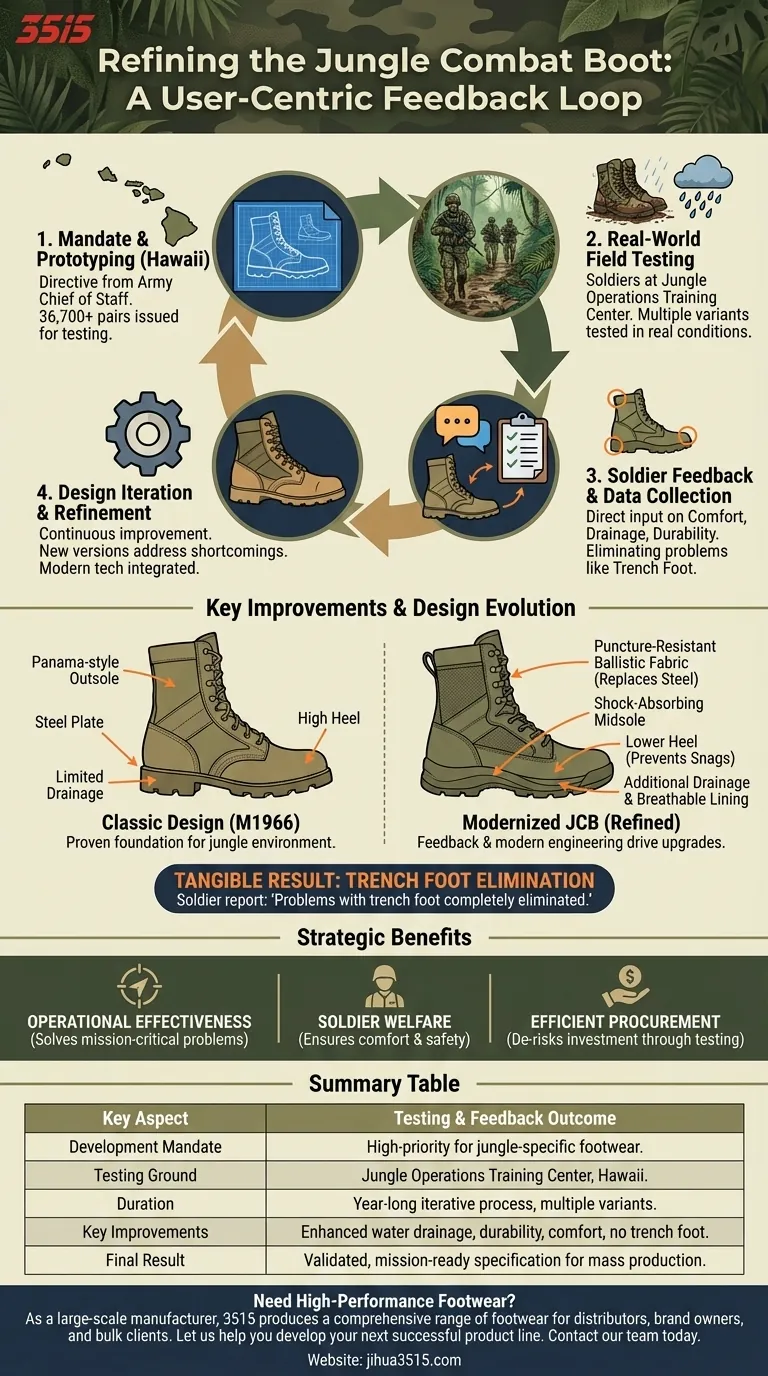

The short answer is that the Jungle Combat Boot (JCB) was refined through a rigorous, year-long iterative testing process. Soldiers at the Jungle Operations Training Center in Hawaii tested multiple boot variants in real-world conditions, and their direct feedback was used to continuously improve the design with each new version.

The core principle behind the boot's development was a user-centric feedback loop. Rather than designing in a vacuum, the Army placed prototype boots on the ground and allowed soldier experience to directly guide the engineering and refinement process, ensuring the final product solved actual operational problems.

The Foundation: A User-Centric Mandate

The development of the JCB wasn't a casual project; it began with a clear directive from the top. This initial push set the stage for a rapid and highly focused development and testing cycle.

From Directive to Development

In September, the Army Chief of Staff mandated the creation of a new jungle boot for two brigade combat teams stationed in Hawaii. This high-level priority led to swift action, with contracts awarded to two U.S. manufacturers by December to produce over 36,700 pairs for testing and initial issue.

The Proving Ground: Hawaii

The Jungle Operations Training Center in Hawaii was selected as the testing ground. This ensured the boots were evaluated by active-duty soldiers in the exact environment for which they were being designed, providing invaluable, real-world performance data.

The Iterative Refinement Loop

The Army's strategy was not to create a perfect boot on the first try. Instead, they embraced a cyclical process of testing, feedback, and improvement that allowed the design to evolve based on evidence.

How the Process Worked

For approximately one year, soldiers wore and evaluated multiple variants of the JCB. Their feedback on performance, comfort, and durability was systematically collected and incorporated into the next iteration of the boot, with each new version addressing the shortcomings of the last.

A Tangible Result: Eliminating Trench Foot

The impact of this feedback was immediate and clear. One soldier reported that after switching from standard-issue desert boots to the JCB prototype, his problems with trench foot during extended wet conditions were completely eliminated.

Key Areas of Improvement

Soldier feedback specifically targeted critical performance areas for a jungle environment. This input led directly to design improvements in features like water drainage, overall comfort during long patrols, and the boot's long-term durability.

Understanding the Design Evolution

The JCB is not a completely new invention but a synthesis of proven concepts and modern technology. The refinement process focused on taking a classic design and upgrading it based on today's material science and manufacturing capabilities.

Learning from the Past

The design team started with the foundation of the iconic M1966 Vietnam-era jungle boot. Key features, such as the mud-shedding "Panama style" outsole, were retained as a proven solution for the environment.

Integrating Modern Technology

Feedback and modern engineering drove significant upgrades. A puncture-resistant ballistic fabric layer replaced the old steel plate, a shock-absorbing midsole was added for comfort, and a lower heel height was implemented to prevent snags on vines and roots. Additional drainage holes, speed laces, and a breathable lining for faster drying were all direct results of this modernization effort.

From Feedback to Final Specification

The entire testing process was designed to culminate in a final, validated product specification ready for mass production.

- If your primary focus is operational effectiveness: The iterative process ensures the final boot directly solves mission-critical problems like trench foot, water drainage, and durability in jungle terrain.

- If your primary focus is soldier welfare: This user-centric approach validates that the equipment is not only effective but also comfortable and safe for the troops who depend on it.

- If your primary focus is efficient procurement: Testing multiple variants de-risks the final investment, ensuring that the design is fully proven before the Army commits to a large-scale production contract.

Ultimately, the JCB's development process demonstrates how to successfully translate direct user experience into a superior, mission-ready piece of equipment.

Summary Table:

| Key Aspect | Testing & Feedback Outcome |

|---|---|

| Development Mandate | High-priority directive for jungle-specific footwear. |

| Testing Ground | Jungle Operations Training Center, Hawaii. |

| Duration | Year-long iterative process with multiple boot variants. |

| Key Improvements | Enhanced water drainage, durability, comfort, and elimination of trench foot. |

| Final Result | A validated, mission-ready specification for mass production. |

Need High-Performance Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring durability, comfort, and performance tailored to your needs.

Let us help you develop your next successful product line.

Contact our team today to discuss your manufacturing requirements and leverage our expertise.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- What materials are commonly used to make combat boots? Discover the optimal blend for durability and performance.

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- What are the primary uses of combat boots? Unmatched Protection for Demanding Environments

- What is the historical significance of combat boots? From Battlefield Necessity to Cultural Icon

- What is the proper method to clean military boots? A Step-by-Step Guide to Maximize Longevity