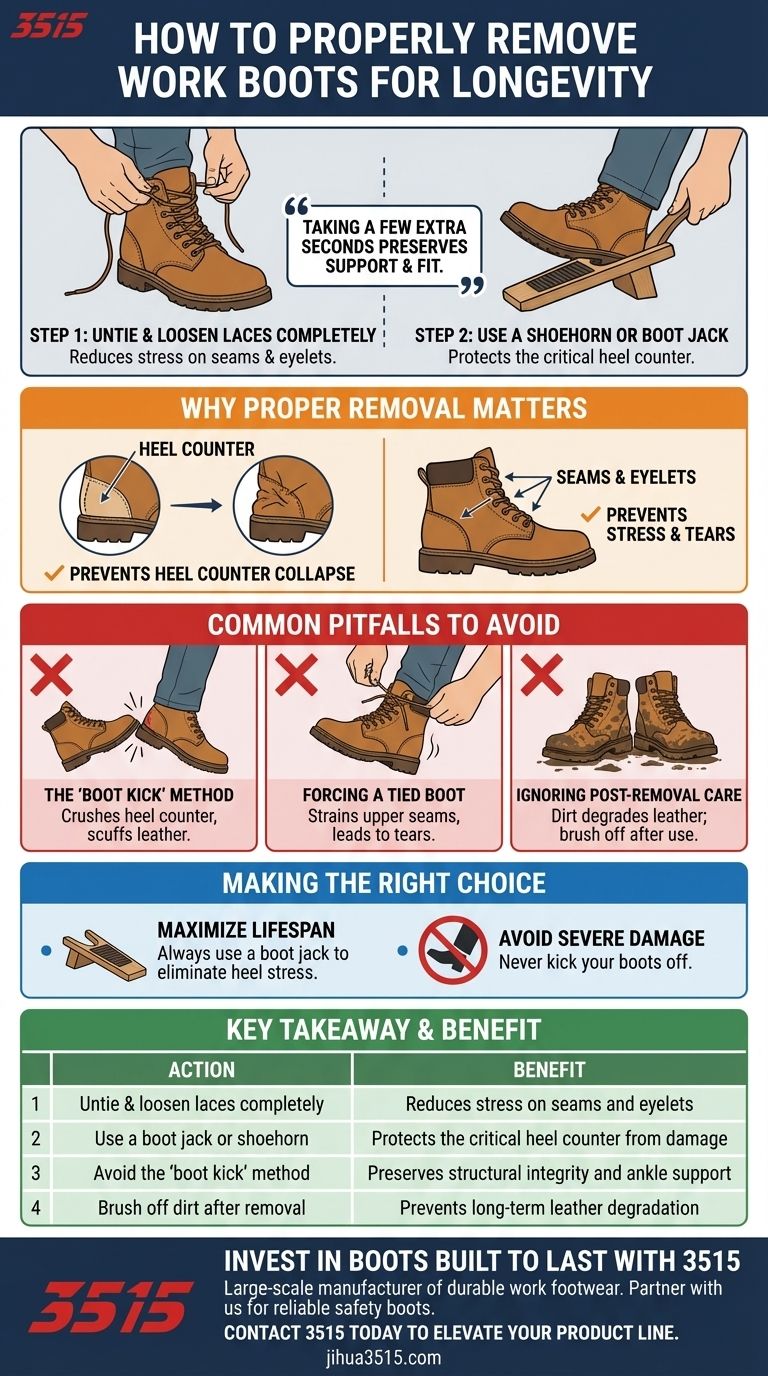

To properly remove your work boots, you must first untie and loosen the laces completely. Then, use a shoehorn or boot jack to slide your foot out, which prevents you from crushing the critical support structure in the heel of the boot.

The method you use to remove your boots is as critical as how you wear them. Taking a few extra seconds for proper removal prevents cumulative damage to the boot's heel counter, preserving the support and fit you rely on.

Why Proper Removal is a Cornerstone of Boot Care

The daily act of taking off your boots seems trivial, but incorrect methods are a primary cause of premature failure. It's the repeated stress on specific components that degrades the boot's integrity over time.

Protecting the Heel Counter

The heel counter is the firm, stiff material at the back of the boot that cups your heel. Its job is to provide stability and prevent your foot from rolling.

When you force a boot off by kicking at the heel with your other foot, you crush this counter. A collapsed heel counter leads to poor fit, blisters, and a significant loss of ankle support.

Preventing Stress on Seams and Eyelets

Forcing a boot off without properly loosening the laces puts immense strain on the stitching and eyelets. This can lead to stretched leather, torn seams, and damaged hardware, compromising the boot's overall structure and water resistance.

Common Pitfalls to Avoid

Developing the right habits means consciously avoiding the shortcuts that cause the most damage. These common mistakes are the fastest way to ruin a good pair of boots.

The 'Boot Kick' Method

The most common mistake is using the toe of one boot to pry off the heel of the other. This action directly crushes the heel counter and scuffs the leather, causing both structural and cosmetic damage with every use.

Forcing a Tied Boot

Simply untying the knot but not loosening the laces is not enough. Yanking your foot out of a tight boot subjects the upper seams and eyelets to concentrated force, leading to tears and stretching over time.

Ignoring Post-Removal Care

The process doesn't end once the boot is off. Leaving dirt, mud, or moisture on your boots after removal allows it to degrade the leather. A quick brush-off should be part of the removal routine.

For a more thorough clean, use lukewarm water, a soft brush, and a mild soap. Avoid harsh detergents, as they can strip the natural oils from the leather and cause it to dry out and crack.

Making the Right Choice for Your Goal

Integrating proper removal into your daily routine is simple and has a significant impact on the longevity of your investment.

- If your primary focus is maximizing lifespan and support: Always fully loosen the laces and use a boot jack or long-handled shoehorn to eliminate all stress on the boot's heel.

- If your primary focus is avoiding the most severe damage: Make it a strict rule to never kick your boots off with your other foot; this single habit change prevents the most common form of structural failure.

These small, consistent actions ensure your work boots continue to provide the protection and support you depend on.

Summary Table:

| Key Takeaway | Benefit |

|---|---|

| Untie and loosen laces completely | Reduces stress on seams and eyelets |

| Use a boot jack or shoehorn | Protects the critical heel counter from damage |

| Avoid the 'boot kick' method | Preserves structural integrity and ankle support |

| Brush off dirt after removal | Prevents long-term leather degradation |

Invest in Boots Built to Last with 3515

Proper care is essential, but it starts with a quality product. As a large-scale manufacturer, 3515 produces a comprehensive range of durable work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots designed for longevity and comfort.

Partner with us to provide your customers with reliable footwear that stands up to the toughest conditions. Contact 3515 today to discuss your manufacturing needs and elevate your product line.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- What dual characteristics do industrial safety boots exhibit? Balance Worker Protection with Health Recovery Efficiency

- What does the 'MT' in ASTM F2413-18 stand for? Essential Metatarsal Protection Explained

- What is the role of industrial footwear within the PPE framework of a palm oil refinery? Expert Safety Guide

- Why is measuring your feet important when buying work boots? Avoid Pain & Boost Safety

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- What are some tips for maintaining and cleaning motorcycle boots? Extend the Life of Your Safety Gear

- Why are high-quality therapeutic boots essential for Diabetic Foot Ulcers? Key Benefits for Recovery & Prevention

- How should work boots be cared for to ensure longevity? A 4-Step Guide to Maximize Durability