To ensure your work boots last, you must adopt a consistent routine of cleaning, conditioning, proper drying, and smart storage. This proactive approach protects the leather, maintains structural integrity, and ensures the boots continue to provide the support and safety you rely on. It transforms a simple purchase into a long-term investment.

The key to longevity isn't a single secret trick, but rather understanding that work boots require a system of regular care. Just like any high-performance tool, consistent maintenance is what prevents irreversible damage and costly replacement.

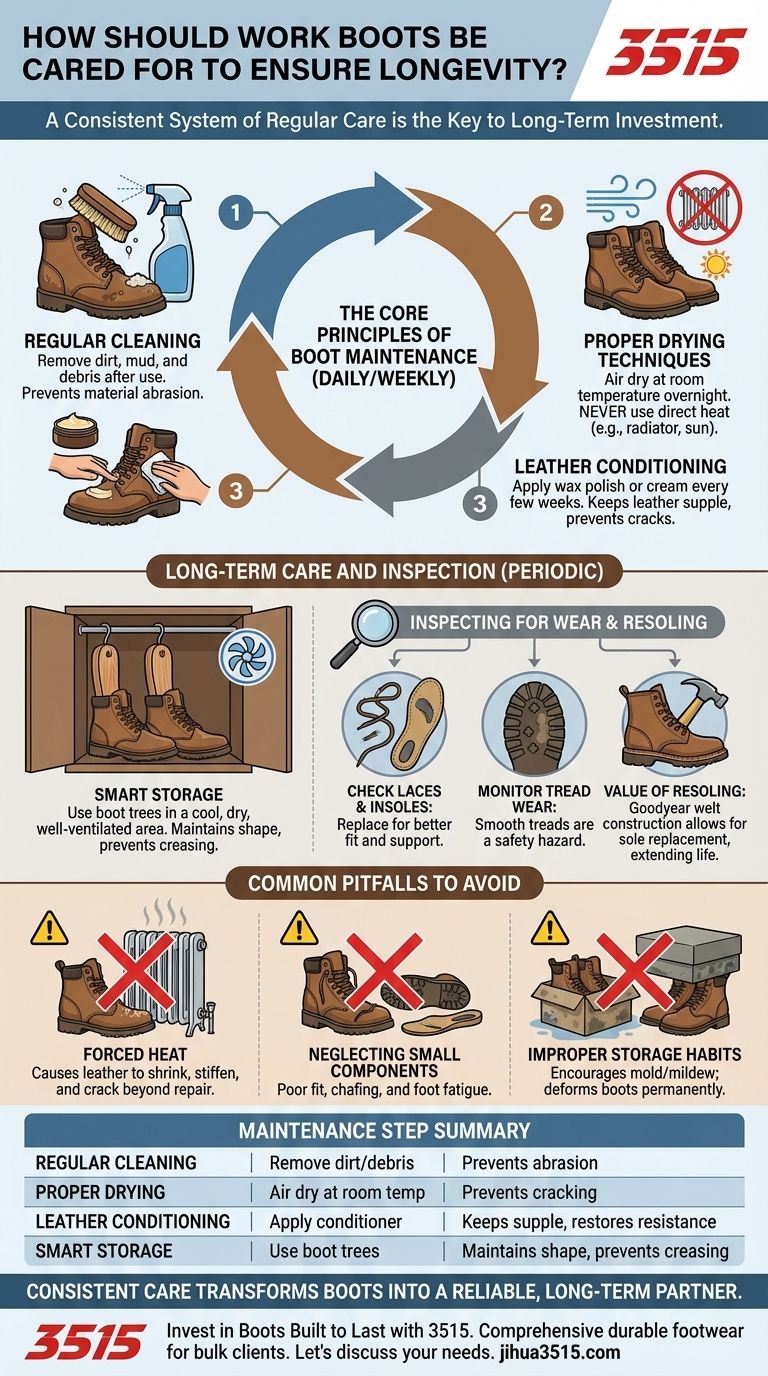

The Core Principles of Boot Maintenance

Proper care is a cycle that begins the moment you get your boots and continues throughout their lifespan. Each step addresses a different type of wear and tear, from daily grime to the slow-drying of leather over time.

Step 1: Regular Cleaning

Dirt, mud, and chemicals are the primary enemies of your boots. They can abrade the material and draw out essential oils from the leather.

A consistent cleaning habit is non-negotiable. For most work environments, a quick clean at the end of the day is sufficient to remove the bulk of debris before it can cause damage.

Step 2: Proper Drying Techniques

How you dry your boots is one of the most critical factors in their longevity. Improper drying can cause more damage than a day of hard work.

Always allow boots to air dry at room temperature overnight. Never use direct heat sources like a radiator, fire, or direct sunlight, as this will cause the leather to crack and become brittle.

Step 3: Leather Conditioning

Leather is a natural material—a skin that needs moisture to stay flexible and strong. Conditioning replenishes the oils that are lost over time and through exposure to the elements.

Condition leather boots every few weeks using a dedicated wax polish, cream, or conditioner. This keeps the material supple, prevents cracks, and can even restore some water resistance.

Long-Term Care and Inspection

Beyond the daily routine, periodic checks and proper storage are essential for extending the life of your boots for years, not just months.

The Importance of Storage

When you're not wearing your boots, where you keep them matters. Improper storage can undo all your hard work.

Store boots in a well-ventilated area away from dampness or direct sunlight. Using boot trees is highly recommended to help them maintain their shape and prevent the leather from collapsing or creasing.

Inspecting for Wear

Regularly check key components for signs of failure. Catching a small problem early prevents it from becoming a major one.

Pay close attention to the outsoles, laces, and insoles. Worn-out laces can compromise fit and support, while degraded insoles reduce comfort. Smooth, worn-down treads on the outsole are a safety hazard that needs to be addressed.

The Value of Resoling

For boots built with a Goodyear welt construction, the sole can be replaced multiple times. This is a powerful feature for extending the life of a high-quality pair.

If the upper part of your boot is still in good condition but the tread is gone, consider taking them to a professional for resoling. This can effectively give your boots a second life.

Common Pitfalls to Avoid

Knowing what not to do is as important as knowing what to do. These common mistakes can dramatically shorten the lifespan of even the most durable work boots.

The Danger of Forced Heat

As mentioned, direct heat is the fastest way to destroy leather. It rapidly pulls moisture from the material, causing it to shrink, stiffen, and crack beyond repair.

Neglecting the Small Components

Ignoring worn-out laces or insoles is a common oversight. Worn laces create a poor fit, leading to chafing and uneven wear, while collapsed insoles fail to provide necessary support, causing foot fatigue.

Improper Storage Habits

Tossing boots in a damp closet or leaving them in a hot truck invites problems. Dampness encourages mold and mildew, while heat and sunlight will dry out and fade the leather. Never stack heavy items on top of your boots, as this will permanently deform them.

Making the Right Choice for Your Goal

Your specific maintenance routine should align with your daily needs and the type of boots you own.

- If your primary focus is maximum durability in harsh conditions: Make frequent cleaning and waterproofing your top priority to protect against moisture and chemical damage.

- If your primary focus is preserving the appearance of leather: Emphasize regular conditioning with quality creams and the consistent use of boot trees to maintain shape.

- If your primary focus is all-day comfort and safety: Regularly inspect and replace your insoles and laces, and monitor outsole tread for wear.

Consistent care transforms your boots from a disposable piece of gear into a reliable, long-term partner in your work.

Summary Table:

| Maintenance Step | Key Action | Why It's Important |

|---|---|---|

| Regular Cleaning | Remove dirt and debris after use. | Prevents material abrasion and damage. |

| Proper Drying | Air dry at room temperature; avoid direct heat. | Prevents leather from cracking and becoming brittle. |

| Leather Conditioning | Apply conditioner every few weeks. | Keeps leather supple and restores water resistance. |

| Smart Storage | Use boot trees in a cool, dry place. | Maintains shape and prevents creasing or mold. |

Invest in Boots Built to Last

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots designed to withstand harsh conditions, and they last even longer when paired with proper care.

Let's discuss your footwear needs. Contact our team today to explore our catalog and discover how our robust work boots can become a long-term investment for your workforce.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the characteristics of synthetic/leather boots? Modern Performance Meets Lightweight Durability

- How can sweat odor be removed from work boots? Eliminate Odor with Proper Cleaning & Drying

- Are Goodyear welted boots worth it? The Ultimate Guide to Lifelong Footwear

- What materials are typically used for the outsole of light work boots? Find the Perfect Balance of Durability & Comfort

- Why is toe protection important in farming and gardening boots? Prevent Crushing Injuries from Heavy Tools and Livestock

- What are the advantages of soft toe work boots? Boost Comfort & Mobility for Long Shifts

- What are the primary dangers of not wearing wildfire boots? The Critical Failure Points That Risk Lives

- How do work boots differ from cowboy boots? Choosing the Right Footwear for Your Job