Ultimately, the right time to waterproof your work boots is dictated by their condition, not a fixed schedule. There is no universal rule, but a clear sign is when you notice water soaking into the leather rather than beading up and rolling off. Depending on your work environment and frequency of use, this could be every few weeks for heavy outdoor use or every few months for lighter, drier conditions.

The most reliable waterproofing strategy is not based on the calendar, but on observation. Proactively treating your boots when their water resistance begins to fail is the key to keeping your feet dry and extending the life of your gear.

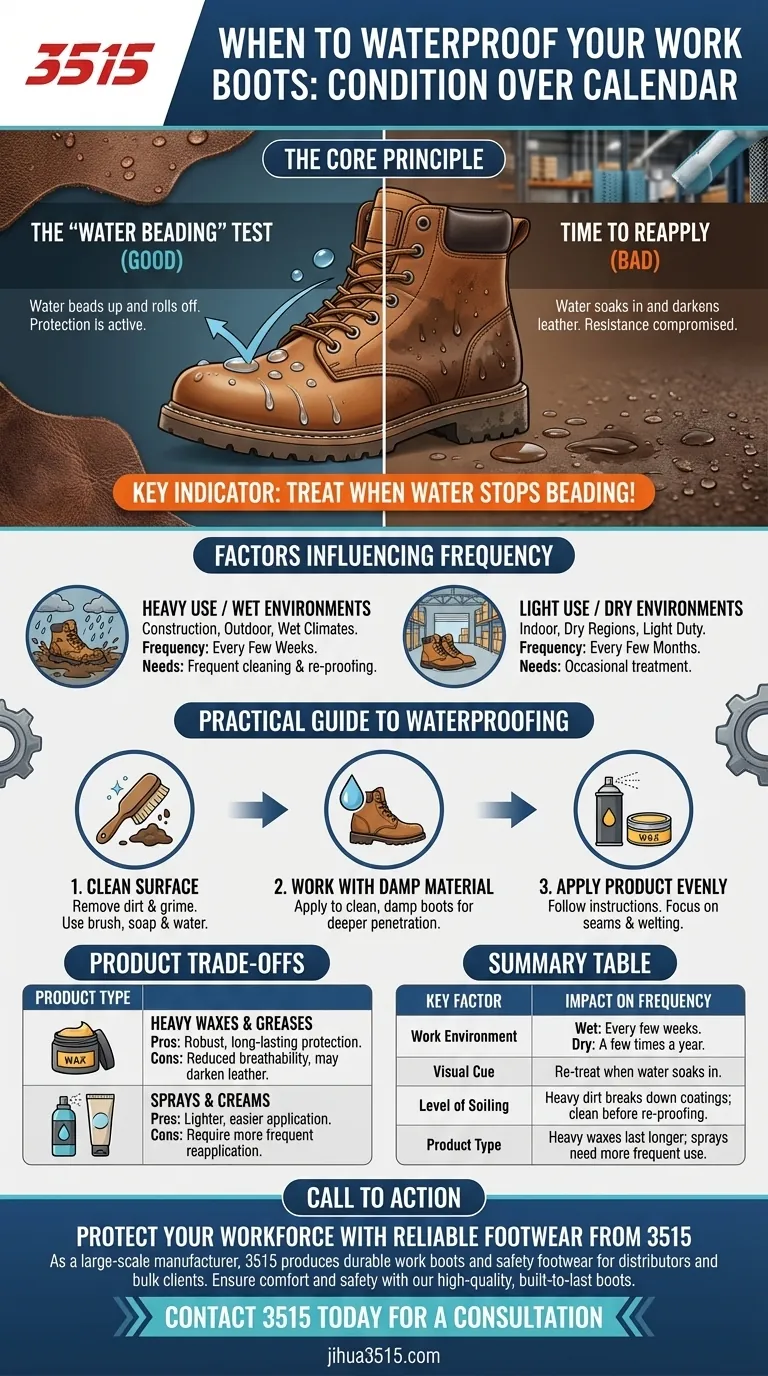

The Core Principle: Condition, Not the Calendar

Relying on a strict schedule—like "the first of every month"—is an inefficient approach. The real factors that determine the need for waterproofing are usage and visual cues.

The "Water Beading" Test

This is your most important indicator. When your boots are new or freshly treated, water should form distinct droplets on the surface and roll off. When you see that water is starting to darken the leather and soak in, water resistance has been compromised, and it's time to reapply a waterproofing treatment.

The Impact of Environment

How and where you use your boots is critical. A construction worker in a wet, muddy climate may need to clean and re-proof their boots every couple of weeks. Conversely, someone working primarily indoors or in a dry region might only need to do it a few times a year.

The Role of Cleaning

Dirt, mud, and grit are abrasive and can break down existing waterproof coatings. A heavily soiled boot loses its water resistance much faster. While you don't need to waterproof after every single cleaning, treating them after a deep clean is an excellent rule of thumb.

A Practical Guide to Effective Waterproofing

Applying a product correctly is just as important as the timing. A proper application ensures the treatment penetrates deeply and provides a durable barrier.

Step 1: Start with a Clean Surface

You cannot effectively waterproof a dirty boot. First, use a brush to remove all dried-on mud and debris. Then, use a simple soap and water solution to gently scrub the surface clean.

Step 2: Work with Damp Material

It may seem counterintuitive, but most waterproofing treatments work best when applied to clean, damp boots. A small amount of moisture in the leather's fibers helps draw the waterproofing agent deeper into the material for more thorough protection.

Step 3: Apply the Product Evenly

Whether you are using a wax, cream, oil, or spray, apply it according to the manufacturer's directions. Pay special attention to seams and welting, as these are common failure points where water is most likely to penetrate.

Understanding the Trade-offs

Waterproofing is a maintenance task that involves balancing protection with material health. More is not always better.

Over-Application Can Be Harmful

Applying waterproofing products too heavily or too frequently can clog the pores in leather, trapping moisture inside and preventing the material from breathing. This can lead to degradation of the leather over time.

Product Choice Matters

Heavy waxes and greases offer the most robust and long-lasting protection but can reduce breathability and may darken the leather. Sprays and creams are often lighter and easier to apply but may require more frequent application to maintain effectiveness.

Treatment vs. Construction

Topical waterproofing treatments are designed to enhance the water resistance of the boot's outer material. They cannot fix fundamental design flaws. A boot without a waterproof membrane or liner and a poorly sealed sole attachment will never be fully waterproof, no matter how much product you apply.

Making the Right Choice for Your Boots

Your maintenance routine should align directly with your work demands and the level of protection you require.

- If your primary focus is maximum protection in harsh, wet conditions: Inspect your boots weekly for water absorption and re-apply a heavy-duty wax or cream after any deep cleaning.

- If your primary focus is general durability in moderate conditions: Rely on the "water beading" test and apply a quality cream or spray whenever you notice performance degrading.

- If your primary focus is extending the life of your boots with minimal effort: Clean your boots regularly and apply an easy-to-use waterproofing spray every couple of months as a preventative measure.

Ultimately, treating your work boots is an act of proactive maintenance that protects both your investment and your comfort on the job.

Summary Table:

| Key Factor | Impact on Waterproofing Frequency |

|---|---|

| Work Environment | Wet/Muddy: Every few weeks. Dry/Indoors: A few times a year. |

| Visual Cue (Water Beading) | Re-treat when water soaks in instead of beading on the surface. |

| Level of Soiling | Heavy dirt and grit break down coatings; clean before re-proofing. |

| Product Type | Heavy waxes last longer; sprays/creams may need more frequent use. |

Protect Your Workforce with Reliable Footwear from 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of durable work boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear designed to withstand harsh conditions.

We help you ensure your team's comfort and safety with high-quality, durable boots that are built to last. Let's discuss how our manufacturing expertise can meet your specific needs.

Contact 3515 today for a consultation and discover the right footwear solutions for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Heavy-Duty Waterproof Steel Toe Work Boots OEM Manufacturer

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What type of leather conditioner is best for full-grain leather boots? Choose Natural Wax-Based for Longevity

- How should suede and nubuck leather work boots be cleaned? A Dry-Cleaning Guide to Preserve the Nap

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- What are the disadvantages of PVC work boots? Uncover the Hidden Costs for Your Workforce

- How have moc toe boots transitioned into modern fashion? From Workwear to Wardrobe Essential

- Are there any recommendations for brands or shopping for packer boots? Focus on Heel, Fit & Construction

- Why is durability important in work boots, and how do cowboy boots meet this need?