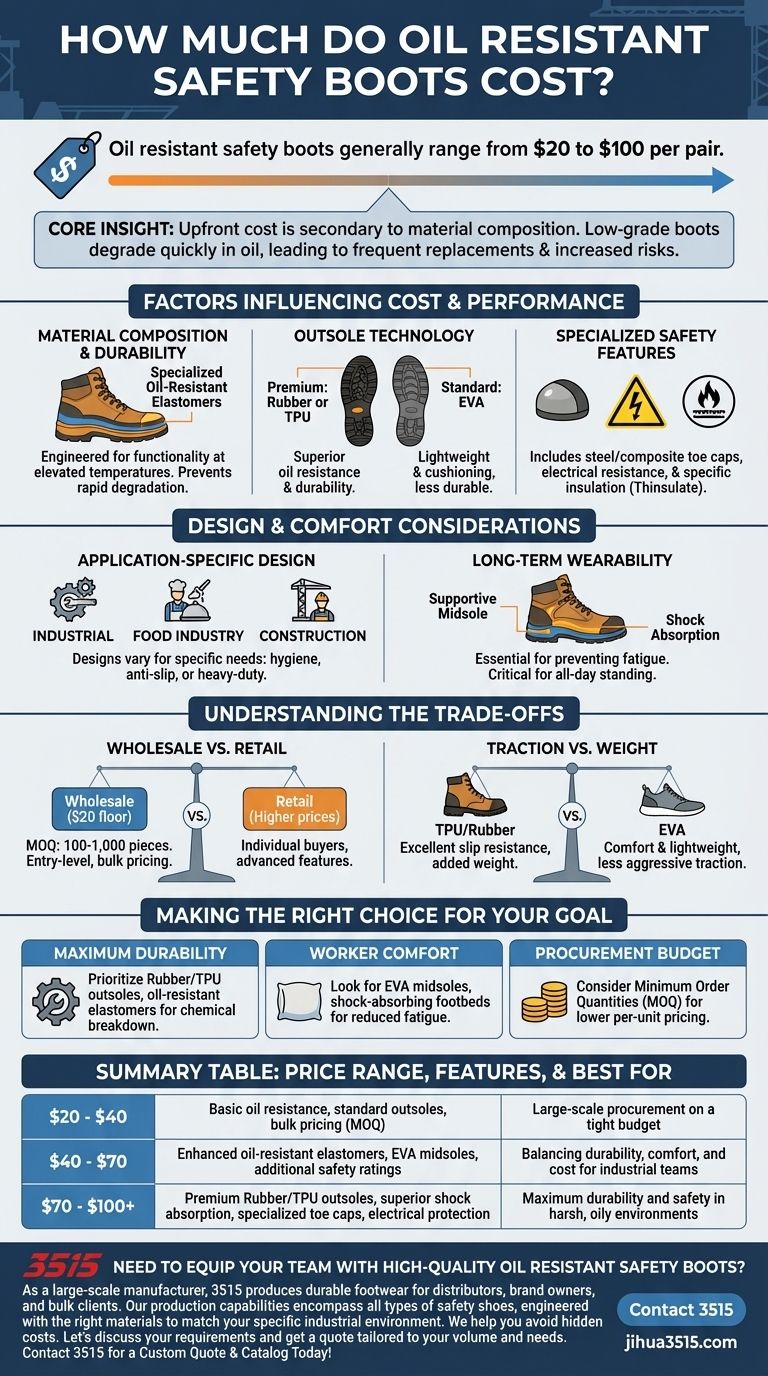

Oil resistant safety boots generally range from $20 to $100 per pair. This wide price variance is dictated by the quality of materials, the specific safety ratings, and the brand reputation. While the lower end of this spectrum often reflects bulk pricing or basic construction, the higher end typically incorporates advanced features like specialized toe caps and superior shock absorption.

Core Insight: The upfront cost of a safety boot is secondary to its material composition. A lower-priced boot that lacks high-grade oil-resistant elastomers will degrade quickly in industrial environments, leading to frequent replacements and increased safety risks.

Factors Influencing Cost and Performance

Material Composition and Durability

The primary driver of cost is the material used in construction. High-quality boots utilize specialized oil-resistant elastomers in the sole, counter, and upper components.

These materials are engineered to maintain functionality and structural integrity even when exposed to oil at elevated temperatures.

Outsole Technology

The outsole is the critical point of failure in oily environments. Premium boots often feature Rubber or Thermo-Polyurethane (TPU) soles.

These materials offer superior oil resistance and durability compared to generic alternatives. Ethylene-vinyl acetate (EVA) is also common, frequently selected for its lightweight and cushioning properties.

specialized Safety Features

Beyond basic oil resistance, the inclusion of protective elements affects the price. This includes toe caps made from steel, aluminum, or composite materials.

Additional safety ratings, such as electrical hazard resistance and specific insulation (like Thinsulate), also contribute to a higher cost basis.

Design and Comfort Considerations

Application-Specific Design

Boots are rarely "one size fits all" regarding their application. Designs vary significantly between industrial use, the food industry, and construction.

For example, a boot designed for the food industry may prioritize specific hygiene and anti-slip standards differently than a heavy-duty construction boot.

Long-Term Wearability

Comfort features are essential for preventing worker fatigue. Higher-end models invest more in supportive midsoles with shock absorption.

A comfortable footbed is critical for professionals who stand all day, directly impacting productivity and health.

Understanding the Trade-offs

Wholesale vs. Retail Quality

The referenced price floor of $20 often correlates with Minimum Order Quantities (MOQ) ranging from 100 to 1,000 pieces.

Individual buyers should be wary of extremely low prices, as these often apply to bulk orders or entry-level boots that may lack advanced longevity features.

Traction vs. Weight

Materials like TPU and Rubber provide excellent slip resistance in oily conditions but can add weight to the boot.

Lighter materials like EVA offer comfort but may not provide the same level of aggressive traction or durability in harsh chemical environments.

Making the Right Choice for Your Goal

To select the correct footwear, you must look beyond the price tag and match the boot's specifications to your specific environment.

- If your primary focus is Maximum Durability: Prioritize boots with Rubber or TPU outsoles and oil-resistant elastomers to withstand chemical breakdown.

- If your primary focus is Worker Comfort: Look for boots featuring EVA midsoles and shock-absorbing footbeds to reduce fatigue during long shifts.

- If your primary focus is Procurement Budget: Consider the Minimum Order Quantities (MOQ) to leverage lower per-unit pricing for large teams.

True value is found when the boot's construction matches the intensity of the environment, ensuring safety without constant replacement.

Summary Table:

| Price Range | Typical Features | Best For |

|---|---|---|

| $20 - $40 | Basic oil resistance, standard outsoles, bulk pricing (MOQ) | Large-scale procurement on a tight budget |

| $40 - $70 | Enhanced oil-resistant elastomers, improved comfort (EVA midsoles), additional safety ratings | Balancing durability, comfort, and cost for industrial teams |

| $70 - $100+ | Premium rubber/TPU outsoles, superior shock absorption, specialized toe caps, electrical hazard protection | Maximum durability and safety in harsh, oily environments |

Need to Equip Your Team with High-Quality Oil Resistant Safety Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the right materials—like oil-resistant elastomers, rubber/TPU outsoles, and protective toe caps—to match your specific industrial environment.

We help you avoid the hidden costs of frequent replacements by providing boots that offer true value through superior durability and safety.

Let's discuss your requirements and get a quote tailored to your volume and needs.

Contact 3515 for a Custom Quote & Catalog Today!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit

- What is the importance of ASTM International in safety footwear standards? Ensure OSHA Compliance and Worker Safety

- How are safety standards addressed in the development of safety shoes? Ensuring Compliance from Design to Delivery

- What does the impact cut test measure in motorcycle boots? Understand CE Level 1 vs. Level 2 Safety

- What is the purpose of static dissipative (SD) footwear? Prevent Static Discharge Hazards

- How does the mechanism of Negativity Bias apply to safety footwear? Safeguard Your Brand Reputation and Compliance

- What are the advantages of composite toe boots compared to steel toe boots? Lighter, Safer & Metal-Free.

- Which footwear series acts as the flagship product line for a large-scale manufacturer? Safety Shoes Core Excellence