In simple terms, the impact cut test measures a motorcycle boot's ability to resist being sliced open by a sharp object during a crash. It simulates a specific and dangerous scenario where your foot strikes sharp metal or road debris with significant force, determining how deep the object penetrates the boot's protective layers.

This test isn't just about cut resistance; it's about resistance to a slicing impact. The results directly indicate how well a boot can protect you from deep lacerations to critical areas like your shin and ankle during a violent, real-world accident.

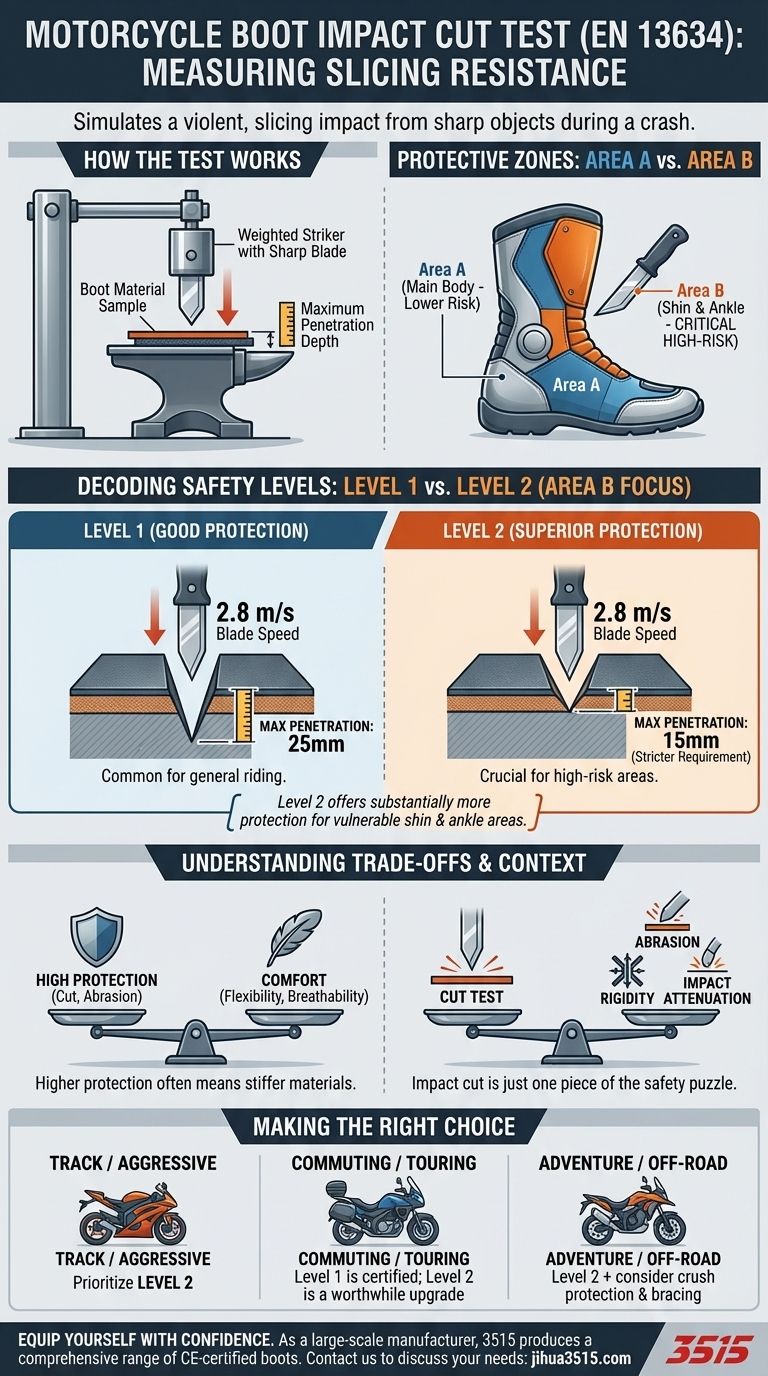

How the Impact Cut Test Works

To understand the safety rating on a boot, you first need to understand how it's tested. The process is designed to replicate the physics of a specific type of crash injury.

The Test Setup

The methodology is straightforward and severe. A sharp blade, mounted on a weighted striker, is dropped from a set height onto samples of the boot's material.

Engineers then measure the maximum depth the blade penetrates into the material. This measurement is the core of the pass/fail criteria.

Defining Protective Zones

The CE standard (EN 13634) recognizes that not all parts of a boot face the same level of risk. It divides the boot into two key zones for this test.

Area A is the main body of the boot upper. Area B covers the critical, high-risk zones, such as the shin and ankle areas, which are more likely to be exposed to severe impacts.

Decoding the Safety Levels: Level 1 vs. Level 2

The difference between a Level 1 and a Level 2 rating comes down to how well the boot performs under increasingly severe conditions, particularly in its most vulnerable areas.

Blade Speed and Impact Force

The test is performed at different speeds to simulate varying impact energy. For Area A, the blade is dropped at a speed of 2.0 meters per second (m/s).

For the more critical Area B, the test is harsher. The blade is dropped at a higher speed of 2.8 m/s, subjecting the material to significantly more impact energy.

Measuring Penetration Depth

This is where the safety levels are defined. The amount of blade penetration allowed determines the rating.

- Level 1: Allows up to 25mm of blade penetration in Area A.

- Level 2: Also allows up to 25mm in Area A, but adds a much stricter requirement for Area B, allowing a maximum penetration of only 15mm.

What Level 2 Really Means

Achieving a Level 2 rating for impact cut resistance demonstrates a substantial increase in protection. It certifies that the most vulnerable parts of your foot and ankle are shielded by materials that can withstand a higher-energy slicing impact with significantly less penetration.

Understanding the Trade-offs

No single test tells the whole story, and higher protection often involves compromises. Being an informed rider means understanding these factors.

Protection vs. Comfort

Materials that offer high levels of cut resistance, like thick leather or advanced composites, are often stiffer and less breathable. A Level 2 boot may feel more rigid and require more break-in time than a more flexible Level 1 boot.

One Piece of a Larger Puzzle

Impact cut resistance is a critical test, but it is not the only one. Certified boots are also tested for abrasion resistance (sliding), transverse rigidity (crushing force across the sole), and impact attenuation (shock absorption).

A great boot provides a balanced performance across all relevant safety tests, not just one.

What the Test Doesn't Measure

This test specifically simulates a slicing impact. It does not measure resistance to a static puncture (like stepping on a nail) or sustained crushing forces from the top or sides of the boot.

Making the Right Choice for Your Goal

Your boot choice should align with your riding style and risk exposure. Use the safety ratings as a tool to make an informed decision.

- If your primary focus is track riding or aggressive canyon carving: Prioritize boots with a Level 2 rating for impact cut resistance, as the risk of encountering sharp debris at high speed is elevated.

- If your primary focus is daily commuting or long-distance touring: A Level 1 boot offers certified protection, but upgrading to Level 2 provides a significant and worthwhile increase in safety for a common crash scenario.

- If your primary focus is adventure or off-road riding: While impact cut resistance is important, you should also heavily weigh factors like crush protection, sole rigidity, and dedicated ankle bracing systems.

Ultimately, understanding what these tests measure empowers you to choose gear that provides the specific protection you need for the way you ride.

Summary Table:

| CE Level | Blade Speed (Area B) | Max Allowed Penetration (Area B) | Key Takeaway |

|---|---|---|---|

| Level 1 | 2.8 m/s | 25 mm | Good protection for general riding. |

| Level 2 | 2.8 m/s | 15 mm | Superior protection for high-risk areas (shin/ankle). |

Equip yourself with confidence. As a large-scale manufacturer, 3515 produces a comprehensive range of CE-certified motorcycle boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring your customers get the safety and quality they demand.

Contact us today to discuss your footwear needs and explore our catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do internal ventilation channels and layered materials enhance comfort? Engineering Airflow in Safety Footwear

- How do ISO, EN, and ANSI safety standards differ? Navigate Global Compliance for Market Access

- What is the strategic market function of high-specification Safety Shoes for footwear distributors? Grow Your Portfolio

- What is the history of firefighter boots? From Leather to Advanced Protective Systems

- What additional specifications should be considered when choosing safety toe boots? Match Your Boot to Your Job's Hazards

- What are the material advantages of recycled rubber powder in safety shoes? Maximize Durability & Cost-Efficiency

- Why are safety shoe materials that comply with OSHA standards critical for risk assessment? Protect Your Workforce

- When did the development of safety footwear begin and what drove its introduction? The Industrial Revolution's Impact on Worker Safety