I'm structuring this as a precise, scannable piece. This means clear headings, short paragraphs, and liberal use of bolding. The format will be a standard Markdown with an opening hook, a core takeaway box, a main body breaking down the "Why," a section on the trade-offs, and then actionable advice, ending with an empowering final statement.

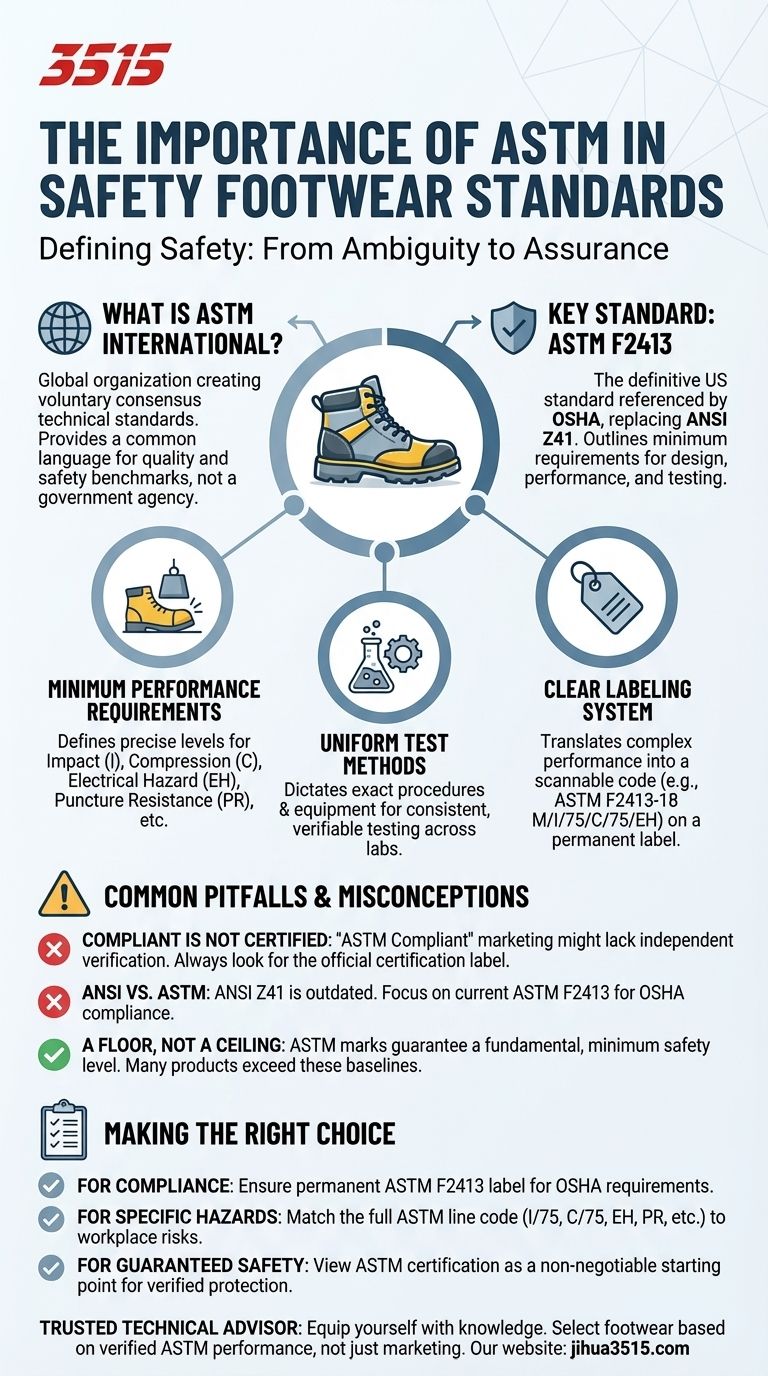

I'll start by synthesizing the references I have. ASTM International (formerly the American Society for Testing and Materials) is a global organization that creates voluntary standards. Its primary function is setting safety standards for things like safety toes and other protective features on footwear. The main standard right now is ASTM F2413, which replaced the older ANSI Z41-1999 standard. OSHA references it. Standards establish minimum requirements and test methods. The goal is to set a solid baseline of quality and safety.

My opening will hook the reader by going right to the heart of the matter: "In the world of safety footwear..." then a direct answer about ASTM being the key organization for defining safe footwear. I'll quickly explain its role in testing and setting minimum requirements.

The core takeaway box will be the article's essence: ASTM standards are the universal language of safety footwear, ensuring a specific, reliable level of protection for the wearer.

The main body will then delve into the “Why”. I'll start with how standards help with the assurance of safety. I'll then break down what exactly ASTM is, and explain that in their absence a "safety boot" could just be a marketing term. I'll also explain ASTM F2413 as the current primary standard. I’ll then detail how the standard defines 'safe' by setting minimum performance requirements, setting uniform test methods and creating a clear labeling system that translates complicated performance requirements into a clear code.

Next comes a section on trade-offs and common misconceptions. Here I will make the key distinction between "ASTM-Compliant" and "ASTM-Certified". I'll also clarify the ANSI vs. ASTM confusion. Finally, I’ll emphasize that a standard is a minimum, not a maximum.

The concluding section will provide actionable advice. I'll offer a bulleted list to clarify how to use the standard to select the right footwear for specific needs, whether it's compliance, specific hazard protection, or overall quality assurance. The final sentence will empower the reader, positioning them as an informed professional.

Finally, I'll review everything to ensure clarity, accuracy, and adherence to the guidelines. The flow from "What" to "Why" should be logical and compelling, and the tone will be both authoritative and empathetic. My goal is to equip the user with the knowledge and confidence to make informed decisions about their safety footwear. In the world of workplace safety, ASTM International is the authoritative body that establishes the technical standards for protective footwear in the United States. It provides the specific, verifiable benchmarks for safety features like impact-resistant toes and electrical hazard protection. This ensures that a "safety boot" is not just a marketing term, but a piece of equipment that has met rigorous, standardized performance requirements.

The core importance of ASTM International is that it translates the concept of "safety" into a measurable, enforceable, and universal standard. It provides the framework that allows employers, workers, and regulatory bodies like OSHA to trust that a piece of footwear will provide a specific, tested level of protection against workplace hazards.

From Ambiguity to Assurance: The Role of a Standard

To understand why ASTM is so critical, we must first appreciate the problem it solves. Without a universal standard, every manufacturer could define "safety" differently, leaving the user with no reliable way to compare products or guarantee protection.

What is ASTM International?

ASTM International, formerly the American Society for Testing and Materials, is a globally recognized leader in developing and publishing voluntary consensus technical standards. It is not a government agency but an independent organization that creates a common language for materials, products, and services.

This organization ensures that products from different manufacturers are tested against the same criteria, providing a level playing field for quality and a clear benchmark for safety.

The Key Standard: ASTM F2413

For protective footwear, the primary standard is ASTM F2413. This is the specification that OSHA (Occupational Safety and Health Administration) references for compliance.

It replaced the older ANSI Z41 standard. While some products may still mention ANSI, ASTM F2413 is the current, definitive document outlining the minimum requirements for design, performance, and testing.

How ASTM Defines and Verifies "Safe"

The ASTM F2413 standard isn't just a single pass/fail grade. It is a comprehensive set of protocols that specifies how footwear must be tested and what level of performance it must achieve to earn a certification.

Setting Minimum Performance Requirements

The standard outlines precise requirements for core safety features. For a safety toe, it defines the exact weight and height of a drop test for impact resistance (I) and the specific force for compression resistance (C).

It also details requirements for other hazards, such as electrical hazard protection (EH), puncture resistance (PR), and static dissipation (SD).

Establishing Uniform Test Methods

Just as important as the performance level is the test method itself. ASTM dictates the exact procedures and equipment that must be used to test the footwear.

This removes variables and guarantees that a boot certified in one lab was subjected to the same stresses as a boot certified in another. This uniformity is the foundation of trust in the system.

Providing a Clear Labeling System

The result of this rigorous testing is a clear, concise labeling system found on a tag inside the footwear. This code is a summary of the boot's certified protections.

A label reading ASTM F2413-18 M/I/75/C/75/EH instantly tells an informed user the boot meets the 2018 version of the standard, is for a male (M), and is certified for the highest levels of impact (I/75) and compression (C/75) resistance, as well as electrical hazard protection (EH).

Common Pitfalls to Avoid

While the ASTM standard provides clarity, misunderstanding its application can lead to compliance issues or a false sense of security.

"Compliant" is Not "Certified"

Be cautious of vague marketing language. A boot that is truly certified to the ASTM F2413 standard has been tested by a third-party laboratory to verify its performance.

Footwear simply described as "ASTM compliant" or "built to ASTM standards" may not have undergone this independent verification. Always look for the official certification label inside the shoe.

The ANSI vs. ASTM Confusion

The reference to the older ANSI Z41 standard can create confusion. For any footwear manufactured after 2005, the relevant standard is ASTM F2413.

OSHA compliance is based on the ASTM standard. While the protection levels from the final ANSI standard are mirrored in the ASTM one, focusing on the current ASTM F2413 label ensures you are referencing the correct and most up-to-date requirements.

A Standard is a Floor, Not a Ceiling

Remember that ASTM F2413 specifies the minimum requirements for a feature to be considered protective. Many manufacturers design footwear that significantly exceeds these baseline standards.

The ASTM mark guarantees a fundamental level of safety, but it does not represent the maximum possible protection available on the market.

Making the Right Choice for Your Goal

Understanding the role of ASTM empowers you to select footwear based on verified performance data. Your specific goal will determine how you use this information.

- If your primary focus is compliance: Look for the permanent ASTM F2413 label inside the footwear to ensure you meet OSHA and workplace requirements.

- If your primary focus is specific hazard protection: Learn to read the full ASTM line code (e.g., I/75, C/75, EH, PR) to precisely match the boot's features to your known workplace risks.

- If your primary focus is guaranteed safety: View the ASTM certification as a non-negotiable starting point, confirming the footwear has passed rigorous, independent, and standardized testing.

By understanding ASTM, you can confidently select footwear based on proven protection, not just marketing claims.

Summary Table:

| ASTM F2413 Standard Component | Purpose | Key Information |

|---|---|---|

| Standard Toe Protection (I/C) | Defines impact & compression resistance levels. | Rated by weight/force (e.g., I/75). Replaced ANSI Z41. |

| Electrical Hazard (EH) | Protects against open circuit accidents. | Must meet 18,000-volt rating. Not for live electrical work. |

| Puncture Resistance (PR) | Shields sole from sharp objects. | Steel or composite plate meets 270-pound force test. |

| Labeling System | Provides clear, scannable certification details. | Look for permanent label inside boot (e.g., ASTM F2413-18 M I/75 C/75 EH). |

Need ASTM-Compliant Safety Footwear You Can Trust?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets the precise requirements of standards like ASTM F2413, guaranteeing the safety, compliance, and quality your business depends on.

Contact our experts today to discuss your specific needs and receive a custom quote.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What factors should be considered when choosing safety shoes? A Complete Guide to Workplace Foot Protection

- How do industrial safety shoes and tactical boots prevent Knee Osteoarthritis? Enhance Joint Health with Precision Gear

- How heavy are firefighter boots? Balancing Critical Protection with On-Scene Mobility

- What tips can help ensure safety toe boots fit correctly? Achieve Optimal Protection & Comfort

- What is a significant advantage of composite safety shoes in workplaces with metal detectors? Unlock Uninterrupted Access and Efficiency

- What type of soles do firefighter boots have and why? Engineered for Extreme Heat & Unmatched Traction

- How does comparative testing on diverse road materials guide the optimization of specialized safety footwear?

- What are the primary functions of industrial-grade safety shoes? Crucial Protection for Construction Safety