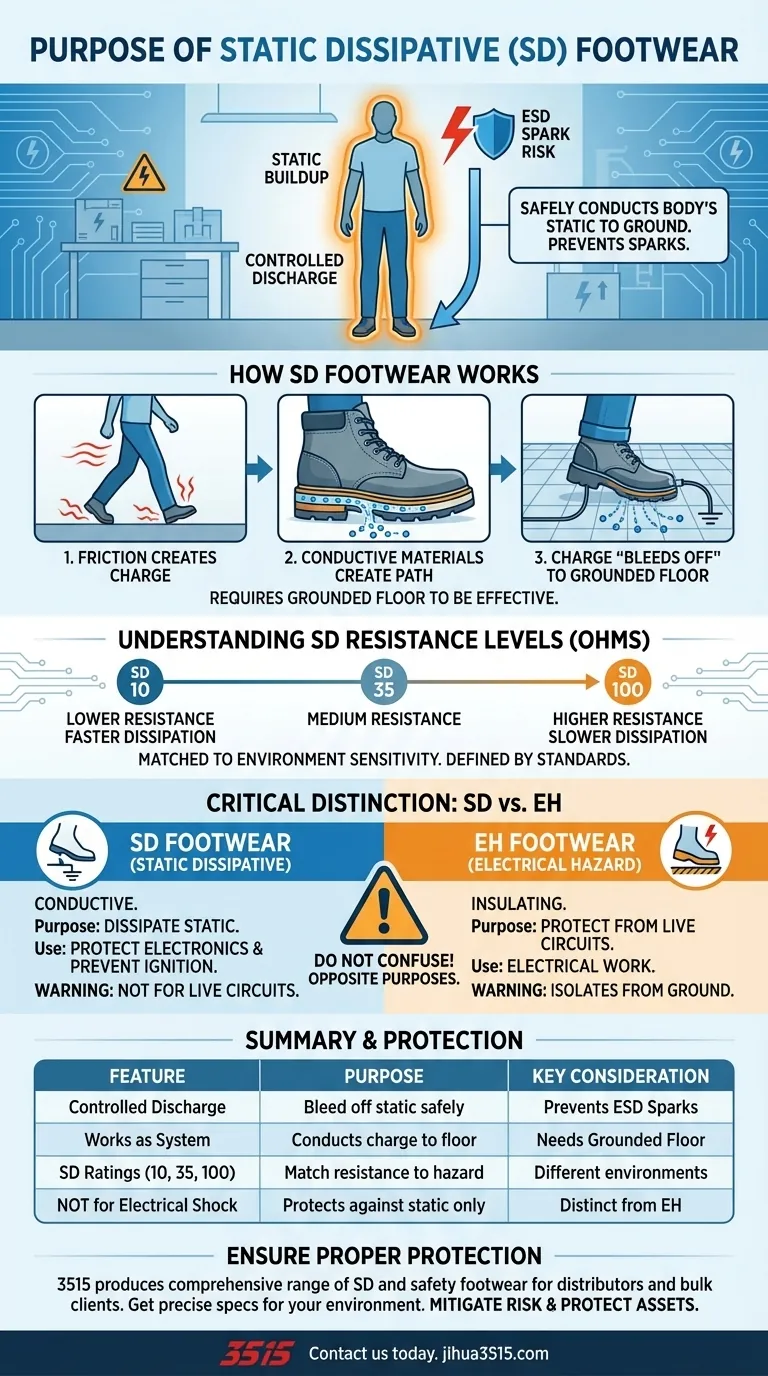

The fundamental purpose of Static Dissipative (SD) footwear is to safely and controllably conduct the body's natural static electricity buildup down into a grounded floor. This controlled discharge prevents a sudden electrostatic discharge (a spark), which can ignite flammable materials or damage sensitive electronic components.

The core function of SD footwear is not merely to get rid of static, but to do so within a specific range of electrical resistance. It acts as a bridge, ensuring static charges flow away from your body at a rate that is safe for both you and your work environment.

How Static Dissipative Footwear Works

To understand SD footwear, you must see it as one component in a complete safety system. The footwear is the critical link between the person and a specialized floor.

The Buildup of Static Charge

Everyday movements, like walking across a floor or pushing a cart, cause friction that can create a static charge on the human body. Without a path to the ground, this charge can build to thousands ofvolts.

Creating a Controlled Path to Ground

SD footwear is constructed with materials that are conductive, but not too conductive. Special soles and insoles create a continuous path from the wearer's foot, through the shoe, and to the floor.

This path allows the static charge to "bleed off" in a slow, controlled manner as it is generated, preventing it from accumulating to a dangerous level where a spark could occur.

The Importance of a Grounded Floor

Static dissipative footwear is ineffective on its own. It absolutely requires a static dissipative or conductive floor that is properly connected to the earth's ground. The shoe moves the charge to the floor, and the floor completes the journey to the ground.

Understanding the SD Resistance Levels

Not all static dissipative footwear is the same. The different ratings correspond to different levels of electrical resistance, which is crucial for matching the footwear to the specific hazards of an environment.

What is Electrical Resistance?

Resistance, measured in Ohms, is the opposition to the flow of an electrical current. In the context of SD footwear:

- Too high a resistance, and the static charge can't bleed off fast enough.

- Too low a resistance, and the charge could flow too quickly, or worse, offer no protection from electrical shock.

The SD Ratings: SD 100, SD 35, and SD 10

These designations classify footwear based on its range of electrical resistance. While specific Ohm values are defined by safety standards, the key concept is that different environments require different levels of protection.

A lower number, like SD 10, generally indicates a lower level of electrical resistance compared to SD 100. This allows for a faster rate of static dissipation.

Why Multiple Levels Exist

The required rate of static discharge depends entirely on the sensitivity of the environment. A facility handling extremely volatile powders might require a faster discharge rate than one assembling sensitive circuit boards. The specific rating is chosen to meet the safety demands of the job.

Common Pitfalls to Avoid: SD vs. EH

One of the most dangerous mistakes is confusing Static Dissipative (SD) footwear with Electrical Hazard (EH) footwear. They are designed for opposite purposes.

The Role of SD Footwear

As discussed, SD footwear is conductive. It is designed to connect you electrically to the ground to dissipate static charge. It provides very limited protection from live electrical circuits.

The Role of EH Footwear

EH footwear is insulating. Its sole and heel are made from non-conductive materials designed to protect the wearer from accidental contact with live electrical circuits. It isolates you from the ground.

The Critical Takeaway

Wearing SD footwear in an environment that requires EH protection is extremely dangerous, as it would provide a direct path for electricity to travel through your body to the ground. Always verify the specific requirement for your workplace.

Making the Right Choice for Your Goal

Selecting the correct footwear is a critical safety decision based on the primary hazards of your work environment.

- If your primary focus is protecting sensitive electronic components: You need SD footwear to prevent static discharge from destroying microchips and other delicate parts.

- If your primary focus is preventing ignition in a flammable or explosive atmosphere: You need SD (or even more conductive) footwear to ensure no static spark can be generated.

- If your primary focus is protecting yourself from live electrical circuits: You must use Electrical Hazard (EH) rated footwear and strictly avoid SD footwear.

Choosing the right safety footwear ensures you are a protected part of your environment's safety system, not a risk to it.

Summary Table:

| SD Footwear Feature | Purpose | Key Consideration |

|---|---|---|

| Controlled Discharge | Safely bleeds off static electricity from the body. | Prevents sudden sparks (ESD). |

| Works as a System | Conducts charge to a grounded floor. | Ineffective without a proper floor. |

| SD Ratings (e.g., SD 10, SD 35) | Different levels of electrical resistance. | Matches the specific hazard level of the environment. |

| NOT for Electrical Shock | Protects against static, not live circuits. | Do not confuse with EH (Electrical Hazard) footwear. |

Ensure Your Workforce is Properly Protected

Choosing the correct safety footwear is a critical decision for workplace safety and productivity. As a large-scale manufacturer, 3515 produces a comprehensive range of SD and other safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the precise specification and rating required for your environment.

Let us help you mitigate risk and protect your assets.

Contact us today to discuss your specific needs and request a quote for reliable, compliant safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene