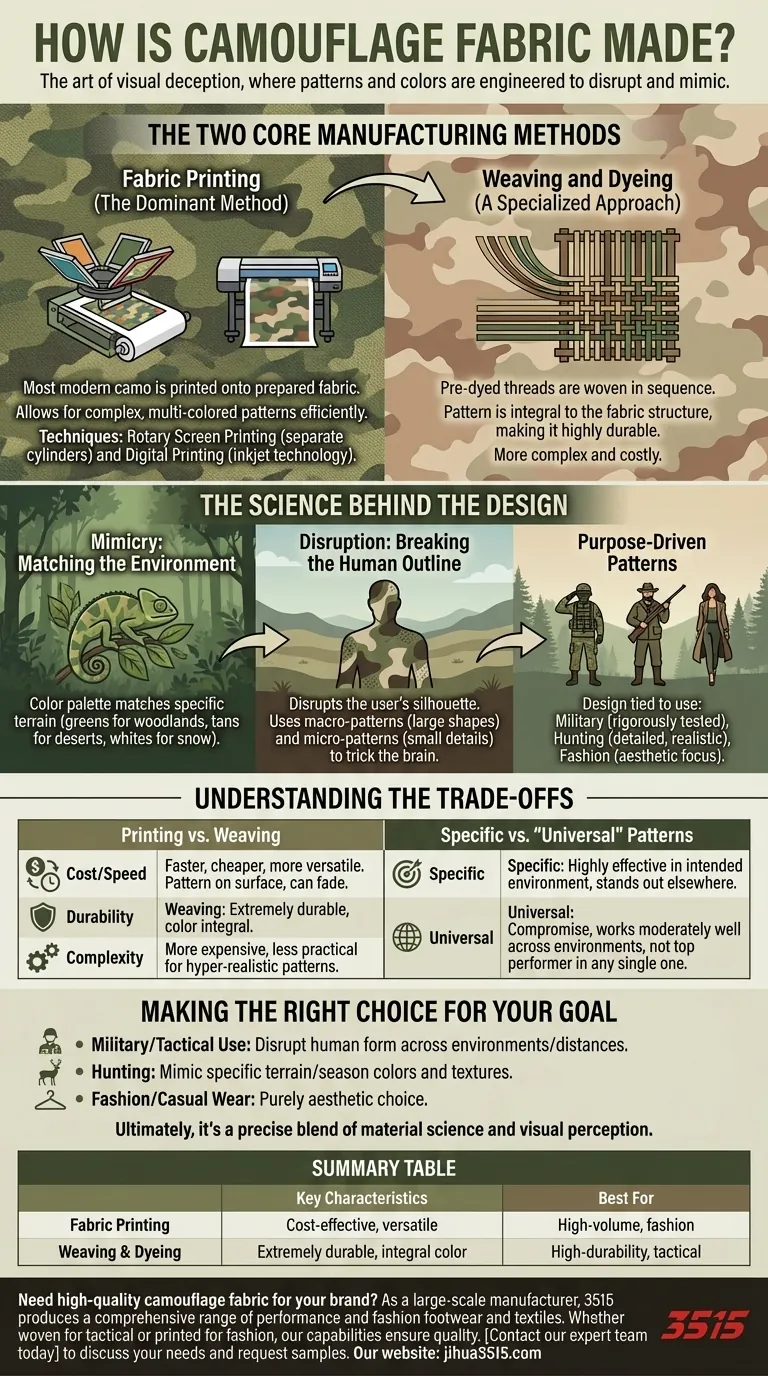

At its core, camouflage fabric is made in two primary ways: by printing patterns onto a base fabric or by weaving pre-colored threads together. The specific method and design are dictated by the environment the camouflage is intended to blend into, whether for military, hunting, or fashion purposes.

The true art of camouflage manufacturing isn't just the physical process of applying color to cloth; it's the science of visual deception, where patterns and colors are engineered to disrupt the human silhouette and mimic the natural environment.

The Two Core Manufacturing Methods

While the goal is always to create a pattern that conceals, the industrial approach to creating that pattern typically falls into one of two categories.

Fabric Printing (The Dominant Method)

Most modern camouflage is created by printing a pattern onto a prepared, often single-color, bolt of fabric. This allows for complex, multi-colored patterns to be produced efficiently and consistently.

Two common printing techniques are rotary screen printing, where different colors are applied through separate patterned cylinders, and digital printing, which uses technology similar to an inkjet printer for extremely high-detail or small-batch patterns.

Weaving and Dyeing (A Specialized Approach)

A less common but highly durable method involves using threads that have been dyed beforehand. These colored threads are then woven together in a specific sequence to create the camouflage pattern directly in the fabric's structure.

This technique is more complex and costly for intricate patterns, but the resulting fabric's color and pattern are integral to the material, meaning they won't fade or wear off in the same way printed patterns can.

The Science Behind the Design

The manufacturing process serves a strategic purpose. The choice of colors and shapes is not random; it's a calculated effort to trick the eye.

Mimicry: Matching the Environment

The most basic principle is mimicry. The color palette of a camouflage pattern is chosen to match the specific terrain it's designed for—greens and browns for woodlands, tans and grays for deserts, and whites for snow.

Disruption: Breaking the Human Outline

Effective camouflage doesn't just blend in; it disrupts the user's silhouette. The human brain is excellent at spotting familiar shapes, especially the human form. Camouflage patterns use macro-patterns (large contrasting shapes) and micro-patterns (smaller, textured details) to break up and obscure this outline, making it harder to recognize.

Purpose-Driven Patterns

The final design is always tied to its intended use. Military patterns are rigorously tested for effectiveness across various light conditions and distances. Hunting patterns are often more detailed and realistic, designed to mimic specific foliage to deceive animals at close range. Fashion camouflage borrows the aesthetic without the strict need for concealment.

Understanding the Trade-offs

Choosing a manufacturing method or pattern involves balancing cost, durability, and effectiveness.

Printing vs. Weaving

Printing is faster, cheaper, and more versatile for creating highly complex patterns. However, the pattern is only on the surface and can fade or wear away with heavy use and washing.

Weaving patterns are extremely durable as the color is part of the thread itself. This method is more expensive and less practical for the hyper-realistic or intricate digital patterns seen today.

Specific vs. "Universal" Patterns

A pattern designed for a specific environment, like a marsh or a pine forest, will be highly effective there but will stand out dramatically elsewhere.

So-called "universal" patterns are a compromise. They are designed to work moderately well in a wide range of environments but will rarely be the top performer in any single one.

Making the Right Choice for Your Goal

The best camouflage is the one that best suits your specific context and needs.

- If your primary focus is military or tactical use: You need a pattern tested for disrupting the human form across multiple environments and distances.

- If your primary focus is hunting: Select a pattern that specifically mimics the colors and textures of the exact terrain and season you'll be in.

- If your primary focus is fashion or casual wear: The choice is purely aesthetic, allowing you to select any pattern or colorway you find appealing.

Ultimately, understanding how camouflage is made reveals that it's a precise blend of material science and the art of visual perception.

Summary Table:

| Manufacturing Method | Key Characteristics | Best For |

|---|---|---|

| Fabric Printing | Cost-effective, versatile for complex patterns, pattern on surface. | High-volume production, fashion, detailed designs. |

| Weaving & Dyeing | Extremely durable, color is integral to fabric, more expensive. | High-durability applications, tactical gear. |

Need high-quality camouflage fabric for your brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of performance and fashion footwear and textiles for distributors, brand owners, and bulk clients. Whether you need durable, woven patterns for tactical gear or cost-effective printed fabrics for fashion lines, our production capabilities ensure quality and consistency.

Contact our expert team today to discuss your specific camouflage fabric needs and request samples.

Visual Guide

Related Products

- Comfortable Block Heel Pumps Wholesale & Custom Factory Production

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Wholesale Leather Derby Shoes Manufacturer | Customizable Business & Dress Footwear

People Also Ask

- What is the purpose of drainage ports in jungle boots? Essential for Rapid Drying in Wet Environments

- What materials are commonly used to enhance the durability of military boots? Discover the Material System for Ultimate Toughness

- What are the disadvantages of combat boots? Heavy, Stiff, and Unsuitable for Many Tasks

- What specialized materials are used in military boots and why? A Guide to Durability & Performance

- What changes were made to jungle boots in the 1980s? A Tale of Innovation and Compromise

- What are the advantages of using military boots for hiking? Durability & Support for Rugged Terrain

- What are the key properties influenced by the materials and production methods of military boots?

- What is boot blousing and why is it important? Master This Essential Uniform Skill