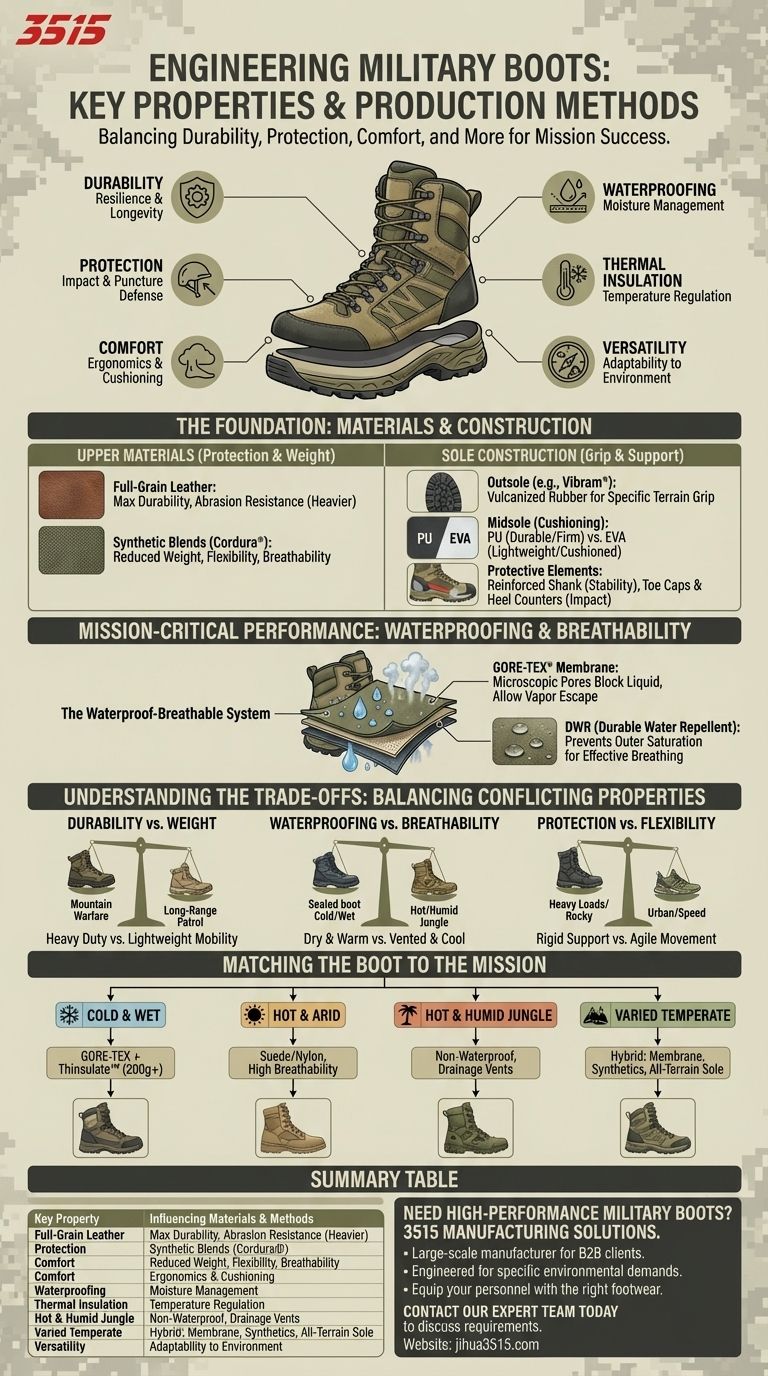

At their core, military boots are complex systems where every material and construction choice directly influences six key properties. These are durability, protection, comfort, waterproofing, thermal insulation, and overall versatility for the intended environment.

The central principle to understand is that no single boot excels in all areas. Each design represents a series of deliberate engineering trade-offs, balancing conflicting properties like waterproofing against breathability or heavy-duty protection against lightweight mobility.

The Foundation: Durability and Protection

A boot's primary function is to protect the wearer's feet from the environment and the rigors of a mission. This is dictated almost entirely by the materials used in its core construction.

Upper Materials: Leather vs. Synthetics

The "upper" is the main body of the boot that covers the foot. Full-grain leather offers the highest level of durability and abrasion resistance but is heavy and requires a break-in period.

In contrast, modern boots often blend leather with synthetic fabrics like Cordura nylon. This reduces weight, improves flexibility, and increases breathability without a significant loss in strength for most applications.

Sole Construction: The Point of Contact

The sole is a multi-layer system. The outsole, often made from a vulcanized rubber compound like Vibram, is engineered for grip and wear resistance on specific terrains.

The midsole provides cushioning and support. Polyurethane (PU) is denser and more durable, offering firm support, while Ethylene-vinyl acetate (EVA), the material in most running shoes, is lighter and offers more cushioning but can compress over time.

Protective Elements

Beyond the main materials, targeted features provide specific protection. A reinforced shank, a rigid piece of material in the midsole, prevents puncture wounds and adds stability on uneven ground. Similarly, reinforced toe caps and heel counters protect against impact.

Mission-Critical Performance: Waterproofing and Breathability

Managing moisture—both from the outside and from sweat—is critical for foot health, comfort, and performance in the field.

The Waterproof-Breathable Membrane

Many modern military boots feature a waterproof-breathable membrane, with GORE-TEX being the most common technology. This is a liner with microscopic pores large enough to let water vapor (sweat) escape but too small for liquid water droplets to penetrate.

The Role of the Outer Material

This membrane works as part of a system. For it to breathe effectively, the boot's outer material must not be saturated with water. This is why leather and synthetic uppers are often treated with a Durable Water Repellent (DWR) finish to make water bead up and roll off.

Understanding the Trade-offs

Selecting the right boot requires understanding the inherent compromises in its design. Excelling in one area often means a reduction in performance in another.

Durability vs. Weight

A heavy, all-leather boot built for extreme mountain warfare offers maximum durability. However, that same weight becomes a significant liability on a long-range patrol over flat terrain, where a lighter nylon and synthetic-leather boot would be far superior.

Waterproofing vs. Breathability

A fully waterproof boot is essential for cold, wet climates to keep feet dry and warm. In a hot and humid jungle environment, that same boot becomes a liability, trapping sweat. Jungle boots are often designed with drainage vents instead of waterproof membranes, built to get wet and dry out quickly.

Protection vs. Flexibility

Rigid ankle support and a stiff sole are critical for carrying heavy loads over rocky, unstable ground. This same rigidity, however, can feel clumsy and restrictive in urban environments or when the mission requires agility and speed.

Matching the Boot to the Mission

Your choice should be dictated entirely by the primary environment and tasks you will face.

- If your primary focus is cold and wet environments: Prioritize a boot with a waterproof GORE-TEX membrane and at least 200g of Thinsulate thermal insulation.

- If your primary focus is hot, arid deserts: Choose a lightweight, highly breathable boot made from suede and nylon, prioritizing ventilation over waterproofing.

- If your primary focus is hot, humid jungles: Select a non-waterproof boot with drainage vents designed to dry quickly after being submerged.

- If your primary focus is varied, temperate terrain: A hybrid boot with a waterproof membrane, synthetic uppers for reduced weight, and a durable all-terrain sole offers the best versatility.

Understanding how materials create performance allows you to select the right tool for the job.

Summary Table:

| Key Property | Influencing Materials & Methods |

|---|---|

| Durability | Full-grain leather, Cordura nylon, vulcanized rubber outsoles (e.g., Vibram) |

| Protection | Reinforced shanks, toe caps, heel counters; Polyurethane (PU) midsoles |

| Comfort & Weight | Synthetic fabric blends, Ethylene-vinyl acetate (EVA) midsoles |

| Waterproofing | GORE-TEX membrane, Durable Water Repellent (DWR) treated uppers |

| Thermal Insulation | Thinsulate liners (e.g., 200g) |

| Versatility | Material selection and design trade-offs (e.g., drainage vents for jungle boots) |

Need High-Performance Military Boots Tailored to Your Mission?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military, tactical, and safety boots. We engineer boots to meet specific environmental demands—whether for cold/wet, hot/arid, or jungle conditions—balancing critical properties like durability, protection, and comfort.

Let us help you equip your personnel with the right footwear for the job.

Contact our expert team today to discuss your specific requirements and explore our manufacturing solutions.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What are the benefits of removable liners in cold-weather boots? Unlock Adaptable Warmth & Dryness

- Can combat boots be worn with a suit? A Guide to High-Risk, High-Reward Style

- What features are considered in the design of military boot soles? The 4 Pillars of Mission-Ready Footwear

- What are the advantages of wireless plantar pressure sensors? Unlock Real-World Gait Analysis for Military Personnel

- What historical event marked the first use of camouflage in military apparel? The Napoleonic Wars' Tactical Shift

- What are the key components of military boot anatomy that affect fit? Unlock Perfect Comfort & Performance

- What are the potential real-world benefits of super boots for soldiers? Boost Endurance & Performance in the Field

- Why is conditioning the leather of military boots important? Essential for Durability & Performance