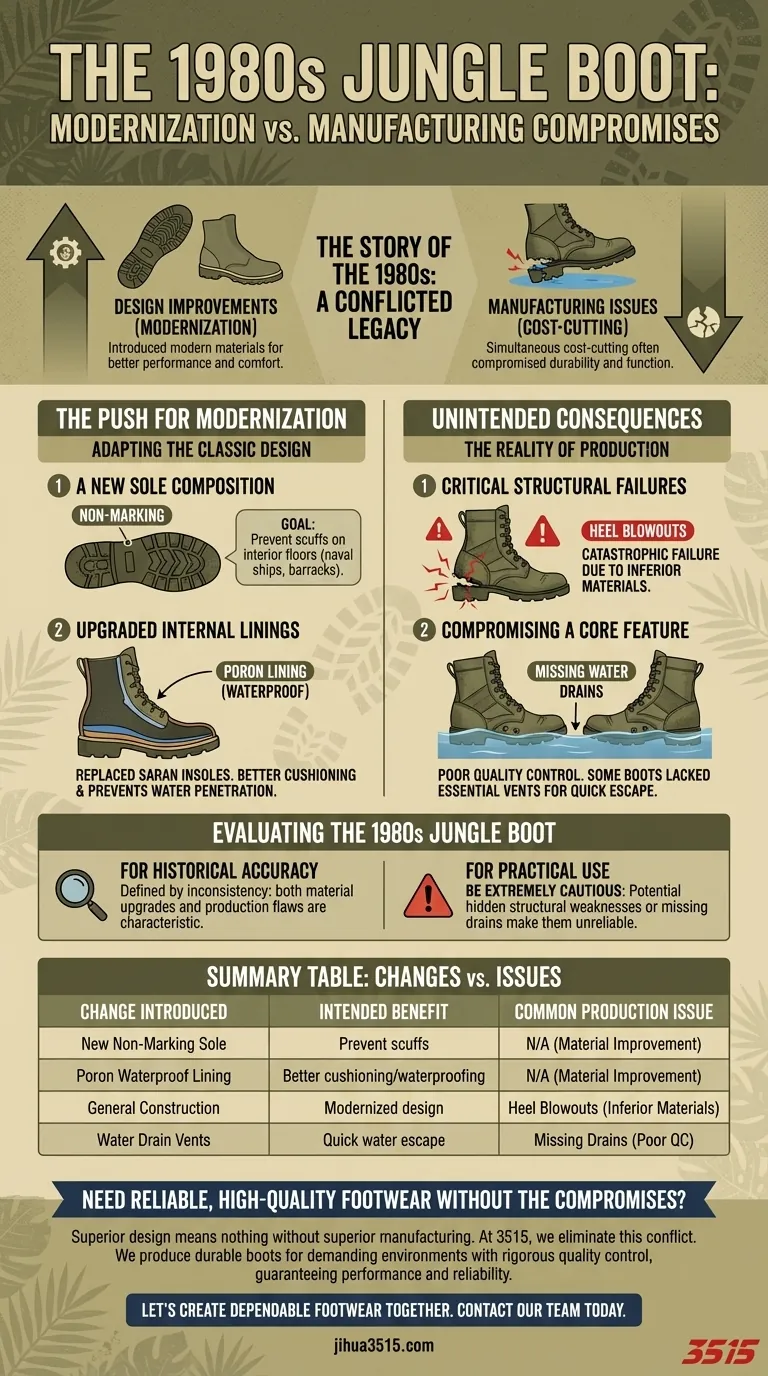

In the 1980s, jungle boots were updated with two key material improvements: a new rubber sole composition and a modern waterproof lining. However, these advancements were often overshadowed by production issues stemming from cost-cutting measures, which led to significant reliability problems.

The story of the 1980s jungle boot is one of conflict. While designers introduced modern materials to improve performance and comfort, simultaneous cost-cutting in manufacturing often compromised the boot's fundamental durability and function.

The Push for Modernization

The changes introduced in the 1980s were intended to adapt the classic jungle boot design to a wider range of environments and improve the user's experience in wet conditions.

A New Sole Composition

The rubber compound used for the boot's sole was altered.

The primary goal of this change was to create a non-marking sole, preventing scuffs and streaks on interior floors, such as those on naval ships or in barracks.

Upgraded Internal Linings

The old-style Saran insoles were replaced with integrated Poron linings.

Poron is a waterproof material designed to offer better cushioning and prevent water from penetrating the boot's interior from the bottom up, representing a significant technological step forward.

The Unintended Consequences of Cost-Cutting

Despite the positive design intentions, the reality of 1980s production was often defined by a push to reduce manufacturing costs. This led to critical failures in materials and construction.

Critical Structural Failures

A common and serious issue reported during this era was heel blowouts.

This refers to the catastrophic failure of the heel structure, often caused by the use of inferior materials that could not withstand the stresses of field use.

Compromising a Core Feature

Perhaps the most significant flaw was the occasional loss of water drains.

The entire principle of a jungle boot is not to keep water out, but to let it escape quickly through metal vents. Poor quality control meant some boots were produced without these essential drains, rendering them completely ineffective in wet environments.

Evaluating the 1980s Jungle Boot

Understanding these changes is key to appreciating the 1980s jungle boot as a transitional piece of gear with a mixed legacy.

- If your primary focus is historical accuracy: Recognize that 1980s-era boots are defined by this inconsistency, with both material upgrades and potential production flaws being characteristic of the period.

- If your primary focus is practical use: Be extremely cautious, as a boot from this decade may have hidden structural weaknesses or lack the critical drainage feature, making it unreliable.

Ultimately, the 1980s jungle boot serves as a clear example of how even thoughtful design improvements can be completely undermined by compromises in manufacturing quality.

Summary Table:

| Change Introduced | Intended Benefit | Common Production Issue |

|---|---|---|

| New Non-Marking Sole | Prevent scuffs on interior floors | N/A (Material improvement) |

| Poron Waterproof Lining | Better cushioning and waterproofing | N/A (Material improvement) |

| General Construction | Modernized design for wider use | Heel Blowouts from inferior materials |

| Water Drain Vents | Essential for quick water escape | Missing Drains due to poor quality control |

Need Reliable, High-Quality Footwear Without the Compromises?

The story of the 1980s jungle boot highlights a critical truth: superior design means nothing without superior manufacturing. At 3515, a large-scale manufacturer, we eliminate this conflict. We produce a comprehensive range of durable footwear—including boots for demanding environments—for distributors, brand owners, and bulk clients. Our rigorous quality control ensures every pair meets the highest standards for materials and construction, guaranteeing the performance and reliability your customers expect.

Let's create dependable footwear together. Contact our team today to discuss your needs.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- Why is waterproofing important in tactical boots? Essential for Foot Health & Mission Success

- What are tactical operations and what do they encompass? Master the Principles for Mission Success

- What is the significance of using professional tactical boots for motion tracking? Ensure Data Precision & Stability

- What are the key features of the new Army Jungle Combat Boot? A Breakdown for Hot & Wet Environments

- What was the primary motivation for developing this new jungle boot? Solving Critical Failures in Tropical Warfare