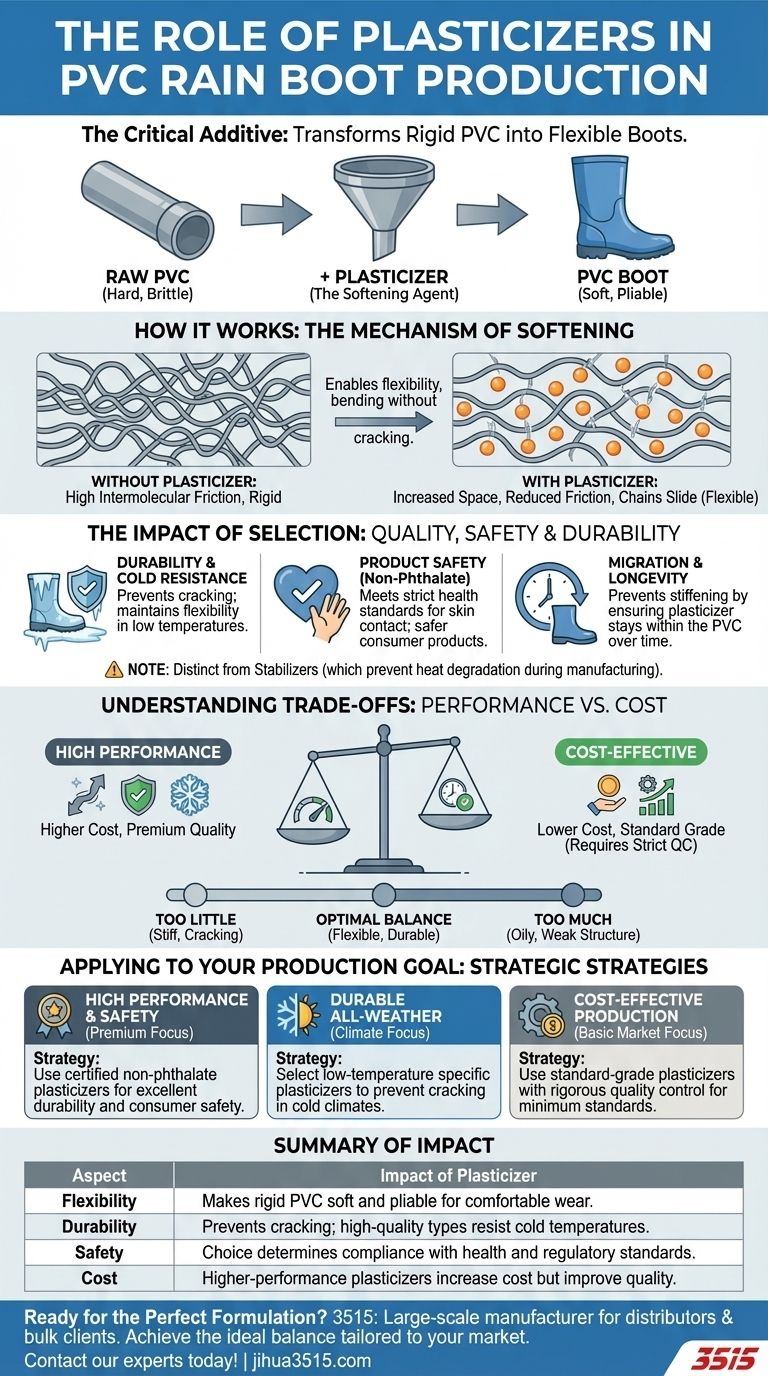

In short, a plasticizer is the critical additive that transforms naturally rigid PVC into the soft, flexible material required for a comfortable and functional rain boot. Its primary role is to increase the material's softness and elasticity, allowing the boot to bend with the foot without cracking.

The choice and amount of plasticizer are the most significant factors in determining a PVC rain boot's final feel, durability, and safety. This single ingredient dictates whether the boot is a premium, long-lasting product or a stiff, low-quality item with potential safety concerns.

Why Raw PVC is Unsuitable for Footwear

From Rigid Pipe to Flexible Boot

Polyvinyl chloride (PVC) in its pure, unmodified state is a hard, brittle plastic. It's the same material often used for pipes, window frames, and credit cards.

This inherent rigidity makes it completely unsuitable for footwear, which must flex and move with the wearer.

The Mechanism of Softening

Plasticizers are small molecules that work their way between the long polymer chains of the PVC. By embedding themselves in this structure, they increase the space between the chains and reduce intermolecular friction.

This allows the polymer chains to slide past one another more easily, translating a rigid material into a pliable one.

The Impact of Plasticizer Selection

Defining Quality and Durability

The specific type and amount of plasticizer used directly correlate to the boot's quality. A high-quality plasticizer can improve resistance to cold temperatures, preventing the boot from becoming brittle and cracking.

The right formulation also ensures the plasticizer doesn't "migrate" or leach out of the PVC over time, which would cause the boot to stiffen and fail prematurely.

Ensuring Product Safety

Safety is a paramount concern. Certain types of plasticizers, particularly some phthalates, are regulated or restricted in many regions due to health concerns.

Manufacturers must select plasticizers that meet strict safety standards for consumer products, especially for items that will be in prolonged contact with skin.

Distinguishing from Other Additives

It's important not to confuse plasticizers with other additives like stabilizers. While a plasticizer provides flexibility, a stabilizer's role is to prevent the PVC from degrading or burning during the high-heat manufacturing process.

Understanding the Trade-offs

Performance vs. Cost

High-performance plasticizers that offer superior flexibility, low-temperature resistance, and a better safety profile are typically more expensive.

Manufacturers must balance the desired product quality and market positioning with the cost of raw materials.

Finding the Right Balance

Using too little plasticizer results in a stiff, uncomfortable boot that is prone to cracking.

Conversely, using too much can make the material feel oily, compromise its structural integrity, and increase the risk of the additive leaching out. The formulation is a precise science.

How to Apply This to Your Production Goal

The ideal plasticizer strategy depends entirely on your final product objective.

- If your primary focus is high performance and consumer safety: Invest in premium, non-phthalate plasticizers that are certified for consumer goods and offer excellent durability.

- If your primary focus is creating a durable, all-weather boot: Select a plasticizer specifically designed for low-temperature flexibility to prevent cracking in cold climates.

- If your primary focus is cost-effective production for a basic market: A standard-grade plasticizer may be sufficient, but rigorous quality control is essential to ensure minimum performance and safety standards are met.

Ultimately, the plasticizer is not just an ingredient but the core determinant of your PVC boot's character and performance.

Summary Table:

| Aspect | Impact of Plasticizer |

|---|---|

| Flexibility | Makes rigid PVC soft and pliable for comfortable wear. |

| Durability | Prevents cracking; high-quality types resist cold temperatures. |

| Safety | Choice determines compliance with health and regulatory standards. |

| Cost | Higher-performance plasticizers increase cost but improve quality. |

Ready to produce high-quality PVC rain boots with the perfect plasticizer formulation?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise ensures your boots achieve the ideal balance of flexibility, durability, and safety, tailored to your market and cost targets.

Contact our experts today to discuss your specific production needs and get a customized solution!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What should adults consider when buying wellington boots? Find the Perfect Fit for Your Needs

- How can you remove odors from rubber boots? Effective Methods for Fresh, Dry Footwear

- How can wellies be styled with skirts and tights? Master the Perfect Layered Look

- Describe the injection molding process for PVC rain boots. High-Speed, Seamless Production

- What are the common issues with cheaper waterproof footwear? Avoid Leaks, Discomfort, and False Economy

- What are the convenience benefits of rubber boots for layering clothing? Master Temperature Control for Safer Hunts

- Why are rubber boots beneficial in hazardous environments? Unmatched Protection & Easy Decontamination

- Who popularized the Wellington boot and how did it get its name? A Story of Practical Design