In short, Goodyear-welted shoes last significantly longer than most other shoes. Their construction is fundamentally designed for repair and renewal, not disposal. Unlike shoes where the sole is simply glued on, a Goodyear-welted shoe can be resoled multiple times, allowing a single pair to last for decades with proper care.

The true value of a Goodyear welt isn't just its initial durability, but its capacity for rebirth. The construction method separates the sole from the upper, allowing a worn-out sole to be replaced repeatedly without compromising the shoe's core structure.

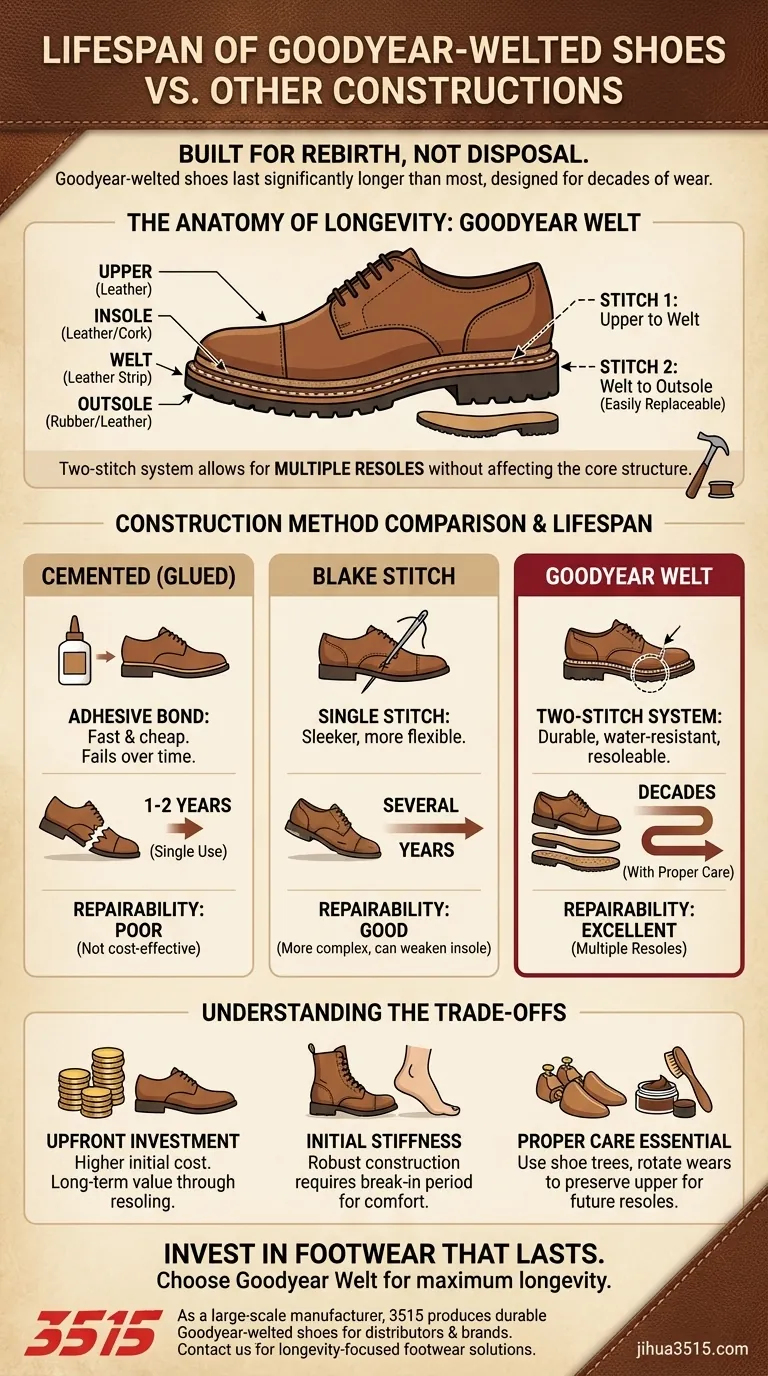

The Anatomy of a Long-Lasting Shoe

To understand the difference in lifespan, you must first understand the construction. It's a question of architecture, not just materials.

What is a Goodyear Welt?

A Goodyear welt is a strip of leather that runs along the perimeter of a shoe's outsole. The construction process involves two independent stitches.

First, the upper is stitched to the welt. Second, the welt is stitched to the outsole. This creates a durable, stable, and water-resistant buffer between the shoe's upper and the part that contacts the ground.

The Key to Unmatched Repairability

This two-stitch system is the secret to the shoe's longevity. When the sole wears down, a cobbler can simply cut the second stitch and attach a brand new sole to the existing welt.

The original, more complex stitch holding the upper to the welt remains untouched. This means you can replace the highest-wear component of the shoe without ever affecting its structural integrity.

How It Compares to Other Methods

The lifespan of a shoe is a direct result of how it's built. The contrast between a Goodyear welt and other common methods is stark.

Cemented Construction (The Most Common)

This is the most widespread method for modern footwear. The upper and sole are attached using a strong adhesive with heat and pressure.

This process is fast and inexpensive. However, the glue bond will eventually fail, and resoling is often impossible or not cost-effective. These shoes are built for a single lifespan.

Blake Stitch Construction (The Sleeker Alternative)

In a Blake-stitched shoe, a single stitch runs directly from the insole through the upper and into the outsole. This creates a more flexible shoe with a closer-cut, sleeker profile than a Goodyear welt.

While more durable than cemented shoes, resoling a Blake-stitched shoe is more difficult. It requires a specific machine, and the process of restitching can puncture and weaken the insole over time.

Understanding the Trade-offs

Choosing a Goodyear welt involves considering its distinct characteristics. It is a superior method for longevity, but it comes with specific trade-offs.

The Upfront Investment

Goodyear welting is a more complex and material-intensive process, which results in a higher initial purchase price. The value is realized over the long term through multiple resoles, which cost a fraction of a new pair.

Initial Stiffness

The robust, multi-layered construction often makes the shoes feel stiffer out of the box. They typically require a break-in period as the leather and cork footbed mold to your feet.

The Need for Proper Care

The potential for a long life is only realized with proper maintenance. Using shoe trees to absorb moisture and maintain shape, along with rotating your shoes between wears, is critical to preserving the leather upper for future resoles.

Making the Right Choice for Your Investment

Your decision should be guided by your primary goal for the footwear.

- If your primary focus is maximum longevity and value over time: The Goodyear welt is the definitive choice, as its unmatched repairability makes it a long-term investment.

- If your primary focus is affordability for occasional use: Cemented construction provides the lowest entry cost but should be considered a disposable item once worn out.

- If your primary focus is a sleek profile and immediate flexibility: A Blake stitch is a strong contender, but you must accept its trade-offs in water resistance and more complex repair.

Choosing a Goodyear welt is not just buying a shoe; it's investing in a durable foundation you can rebuild for years to come.

Summary Table:

| Construction Method | Key Feature | Average Lifespan | Repairability |

|---|---|---|---|

| Goodyear Welt | Two-stitch system, welt strip | Decades (with resoling) | Excellent (can be resoled multiple times) |

| Blake Stitch | Single stitch, sleek profile | Several years | Good (more complex resoling) |

| Cemented (Glued) | Adhesive bond | 1-2 years (single use) | Poor (often not cost-effective) |

Ready to invest in footwear that lasts for decades?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable Goodyear-welted shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive footwear built for longevity and customer satisfaction.

Contact us today to discuss your footwear needs and discover the 3515 advantage!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What should workers consider when selecting comfortable work boots? Prioritize Material, Fit, and Safety

- Why might some firefighters resist switching from leather to rubber boots for hazmat responses? Comfort vs. Cost

- Why is it important to maintain waterproof leather boots? Extend Lifespan & Performance

- What makes Western work boots durable and long-lasting? The Trifecta of Quality Materials, Repairable Construction & Design

- What alternative footwear options are suggested for winter biking? Save Money on Warm Winter Boots

- What factors should be considered when choosing work boots? Prioritize Safety, Fit, and Durability

- What is the purpose of the midsole in work boots? Enhance Comfort, Safety & Durability

- What are the risks of not wearing proper work-safe boots? Avoid Costly Injuries & Downtime