The durability of a Western work boot is no accident. It is the direct result of a purpose-built system combining high-quality materials like full-grain leather, robust construction methods such as Goodyear welting, and a design philosophy focused on withstanding demanding work environments. These elements work together to create a boot that is not only tough but often repairable, dramatically extending its service life.

True longevity in a work boot is not about a single feature, but a trifecta of quality materials, repairable construction, and diligent maintenance. Understanding this system allows you to look past marketing and identify a boot that offers genuine, long-term value.

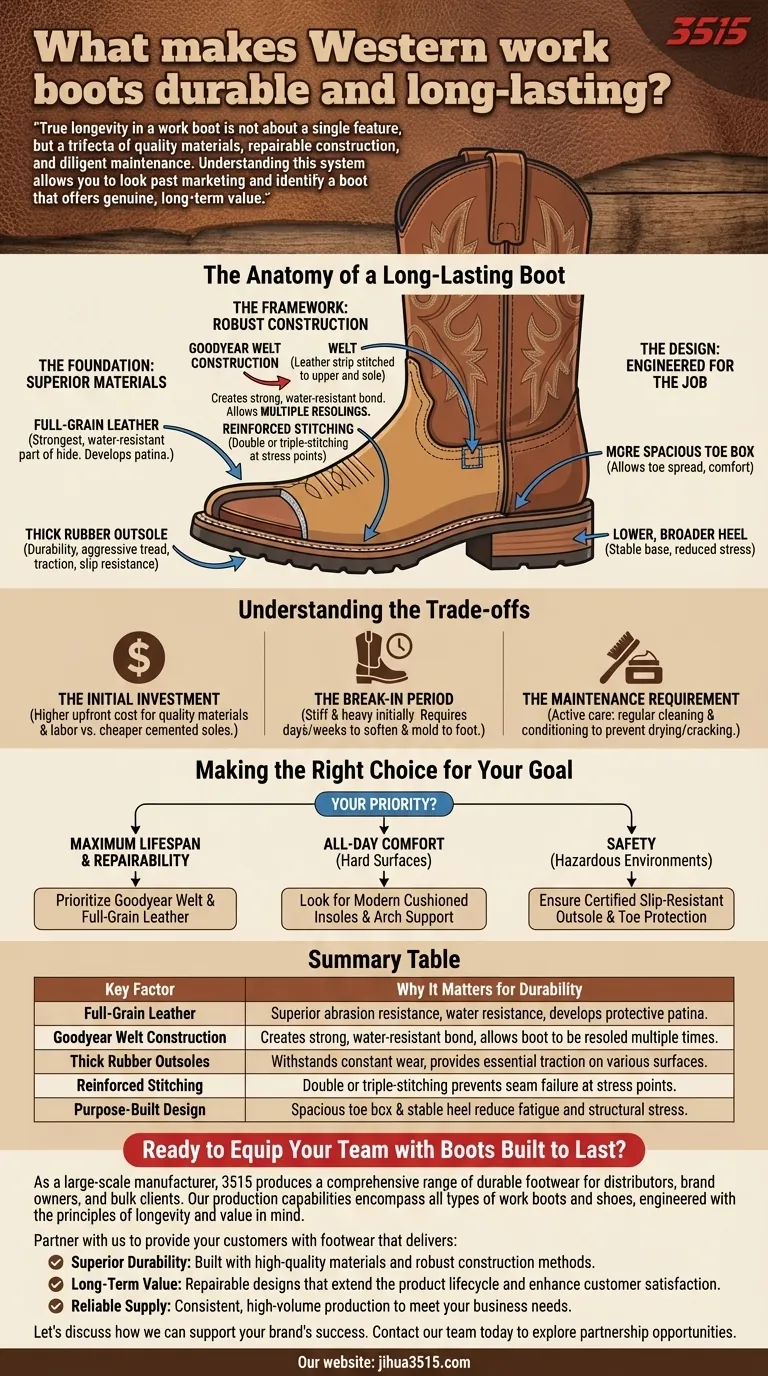

The Anatomy of a Long-Lasting Boot

A durable boot is engineered from the ground up. Each component is chosen specifically to contribute to the strength and resilience of the whole, ensuring it can handle the stress of long hours on your feet.

The Foundation: Superior Materials

High-quality leather is the first key ingredient. Top-tier boots often use full-grain leather, which is the strongest and most water-resistant part of the hide. It stands up to abrasion and, with care, develops a unique patina over time.

The sole is equally critical. Western work boots utilize thick rubber outsoles with aggressive tread patterns. This provides not only durability against constant wear but also essential traction and slip resistance on varied surfaces.

The Framework: Robust Construction

The single most important factor for a long lifespan is Goodyear welt construction. This method involves stitching a leather strip (the "welt") to the boot's upper and then stitching the sole to that welt.

This creates an incredibly strong and water-resistant bond. Most importantly, it allows a cobbler to easily remove the old sole and attach a new one, meaning you can resole the boot multiple times.

Beyond the welt, look for reinforced stitching throughout the boot, especially at stress points. Double or triple-stitching ensures the seams won't fail when the boot is flexed or strained.

The Design: Engineered for the Job

Durability is also a function of a design that reduces fatigue and failure. Western work boots typically feature a more spacious toe box, allowing your toes to spread out and providing comfort during long shifts.

They also have a lower, broader heel than traditional Western riding boots. This provides a more stable base for walking and standing, reducing stress on both your feet and the boot's structure.

Understanding the Trade-offs

No design is without its compromises. True durability comes with considerations you must be aware of before investing in a high-quality pair of boots.

The Initial Investment

The materials and labor required for features like Goodyear welting and full-grain leather uppers result in a higher upfront cost. Boots with cemented or glued soles are cheaper initially but cannot be repaired and must be replaced.

The Break-in Period

Robust construction and thick leather mean these boots are often stiff and heavy out of the box. They require a break-in period of several days or weeks to allow the leather to soften and mold to your foot's unique shape.

The Maintenance Requirement

Durability is not a passive quality. To maximize the boot's lifespan, you must actively maintain it. This means regular cleaning to remove abrasive dirt and periodic conditioning to keep the leather from drying out and cracking.

Making the Right Choice for Your Goal

Your ideal boot depends on balancing maximum durability with the specific demands of your work.

- If your primary focus is maximum lifespan and repairability: Prioritize boots with a Goodyear welt construction and full-grain leather uppers, as these are the cornerstones of a long service life.

- If your primary focus is all-day comfort on hard surfaces: Look for models that include modern cushioned insoles and excellent arch support in addition to a durable build.

- If your primary focus is safety in a hazardous environment: Ensure the boot has a certified slip-resistant outsole and the appropriate toe protection (steel, composite, or soft) for your job site.

Choosing a well-made Western work boot is investing in a tool that, with proper care, will protect and support you for years to come.

Summary Table:

| Key Factor | Why It Matters for Durability |

|---|---|

| Full-Grain Leather | Superior abrasion resistance, water resistance, and develops a protective patina. |

| Goodyear Welt Construction | Creates a strong, water-resistant bond and allows the boot to be resoled multiple times. |

| Thick Rubber Outsoles | Withstands constant wear and provides essential traction on various surfaces. |

| Reinforced Stitching | Double or triple-stitching at stress points prevents seam failure. |

| Purpose-Built Design | A spacious toe box and stable, broad heel reduce fatigue and structural stress. |

Ready to Equip Your Team with Boots Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, engineered with the principles of longevity and value in mind.

Partner with us to provide your customers with footwear that delivers:

- Superior Durability: Built with high-quality materials and robust construction methods.

- Long-Term Value: Repairable designs that extend the product lifecycle and enhance customer satisfaction.

- Reliable Supply: Consistent, high-volume production to meet your business needs.

Let's discuss how we can support your brand's success. Contact our team today to explore partnership opportunities.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How are insulated boots rated for different temperature conditions? Match Your Activity Level for Optimal Warmth

- How do work boot materials impact worker efficiency and safety? Match Materials to Your Work Environment

- Is the toe box a critical component of boot fit? Focus on the 3 pillars for a perfect fit.

- What features should construction and industrial work boots have? Essential Safety & Protection Guide

- What is the primary purpose of lace-to-toe boots? Achieve a Perfect, Customizable Fit

- How do safety features in work boots contribute to overall comfort and safety? Unlock the Secret to All-Day Protection

- What makes Chemical Resistant boots durable and reliable? A Guide to Multi-Layer Protection

- Why is breathability important in fire boots? The Critical Link to Safety and Performance