Outsole traction is a foundational element of workplace safety. It directly mitigates risk by increasing the coefficient of friction between footwear and a walking surface. This single factor is crucial in preventing slips, trips, and falls, which were responsible for approximately 32% of all nonfatal workplace injuries that required time off in 2019.

The primary role of a slip-resistant outsole is not just to "grip" the floor, but to function as an engineered system that actively maintains contact with a surface, especially in the presence of contaminants like water, oil, or dust.

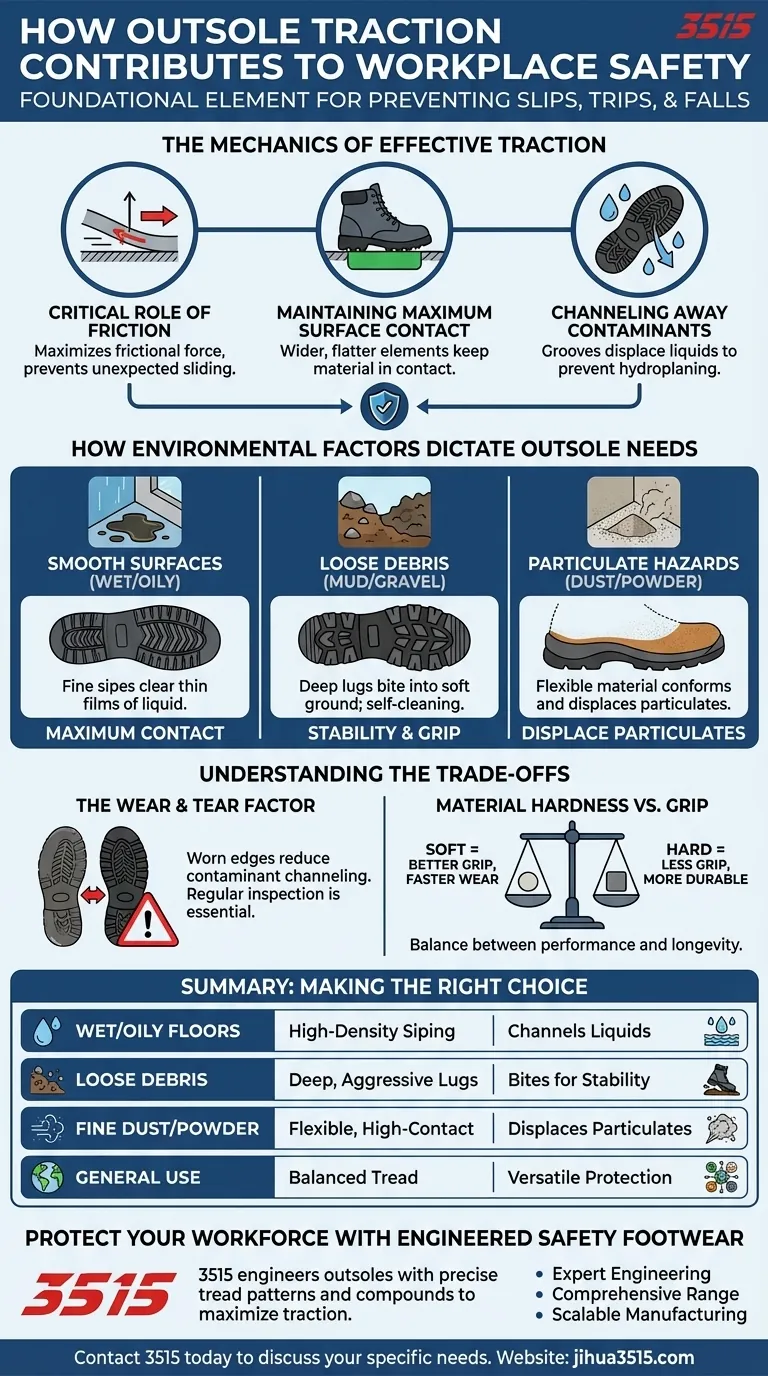

The Mechanics of Effective Traction

A common misconception is that traction is simply about soft, "grippy" rubber. The reality is a sophisticated interplay between material science and physical design, engineered to overcome specific environmental hazards.

The Critical Role of Friction

At its core, traction is a function of friction. A high-traction outsole maximizes the frictional force between the shoe and the ground, preventing the foot from sliding unexpectedly when force is applied, such as when walking, pushing, or turning.

Maintaining Maximum Surface Contact

The tread pattern on an outsole is designed to keep as much of the outsole material in contact with the walking surface as possible. Wider, flatter tread elements are often used for smooth, dry surfaces to maximize this contact area.

Channeling Away Contaminants

This is arguably the most important function of an outsole's tread design in hazardous environments. The channels, or grooves, in the pattern are engineered to displace liquids like water and oil. By quickly moving these contaminants away from the load-bearing surfaces of the tread, the outsole can make solid contact with the floor itself, preventing hydroplaning and a subsequent slip.

How Environmental Factors Dictate Outsole Needs

The effectiveness of any outsole is entirely dependent on the environment in which it's used. A design that excels in one scenario can be a liability in another.

Smooth Surfaces with Liquid Hazards

Environments like commercial kitchens, garages, or manufacturing floors are often contaminated with water, grease, or oil. Here, the ideal outsole has a pattern of very fine, sharp-edged slits called sipes. These micro-channels are extremely effective at clearing thin films of liquid.

Loose Debris and Uneven Terrain

For outdoor environments like construction sites, the primary hazard is often loose material like dirt, gravel, or mud. An outsole designed for this requires deep, aggressive lugs with wide spacing. This design bites into the soft ground for stability and is "self-cleaning," meaning it sheds debris easily instead of getting clogged.

Particulate and Dust Hazards

Fine powders or dust on a smooth floor can act like microscopic ball bearings, creating a dangerously slick surface. A high-contact, flexible outsole material is needed to conform to the floor surface and displace these fine particulates.

Understanding the Trade-offs and Limitations

No single outsole is perfect for every situation. Acknowledging the limitations of your equipment is a key part of any effective safety program.

The Wear and Tear Factor

Traction is not permanent. As an outsole wears down, the edges of the tread pattern become rounded and the channel depth decreases. This severely reduces its ability to channel away contaminants, drastically lowering its slip resistance long before the shoe looks "worn out." Regular inspection of footwear is essential.

Material Hardness vs. Grip

Softer rubber compounds generally offer better grip on smooth, dry surfaces but wear out much faster. Harder compounds are far more durable and resistant to chemicals and abrasion but typically provide less friction. The choice of material is always a balance between performance and longevity.

Design-Specific Performance

An outsole with deep lugs designed for mud will have very little surface area in contact with a smooth, wet floor, making it a significant slip hazard in that context. The opposite is also true. The tread design must be matched to the most common hazard.

Making the Right Choice for Your Goal

Selecting the correct footwear is a critical control measure for workplace safety. Use the primary environmental hazard as your guide.

- If your primary focus is smooth, wet, or oily indoor surfaces: Prioritize outsoles with high-density siping and a softer rubber compound to maximize liquid displacement and surface contact.

- If your primary focus is on loose earth, mud, or uneven outdoor terrain: Choose a boot with deep, widely spaced lugs made from a durable compound to ensure stability and longevity.

- If your primary focus is on mixed indoor/outdoor use with minimal contamination: A balanced, multi-purpose tread pattern with moderate depth and good surface contact offers the most versatile protection.

Ultimately, understanding that an outsole is a piece of safety engineering—not just a shoe bottom—is the key to reducing preventable workplace injuries.

Summary Table:

| Workplace Hazard | Recommended Outsole Feature | Key Benefit |

|---|---|---|

| Wet/Oily Floors | High-Density Siping | Channels away liquids for maximum contact |

| Loose Debris (Gravel, Mud) | Deep, Aggressive Lugs | Bites into soft ground for stability |

| Fine Dust/Powder | Flexible, High-Contact Material | Conforms to surface to displace particulates |

| General Indoor/Outdoor | Balanced, Multi-Purpose Tread | Versatile protection for mixed environments |

Protect Your Workforce with Engineered Safety Footwear

As a leading manufacturer, 3515 produces a comprehensive range of slip-resistant footwear designed for the specific hazards your team faces. We engineer outsoles with the precise tread patterns and rubber compounds needed to maximize traction and minimize workplace injuries.

Our Value to Distributors, Brand Owners, and Bulk Clients:

- Expert Engineering: We design outsoles based on the science of friction and contaminant displacement.

- Comprehensive Range: From kitchen-safe shoes with micro-siping to construction boots with deep lugs, we have a solution for every environment.

- Scalable Manufacturing: As a large-scale manufacturer, we can meet the demands of any order size with consistent quality.

Ready to equip your workforce with the right defense against slips and falls?

Contact 3515 today for a consultation to discuss your specific needs and discover our full catalog of safety footwear.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What are some methods to make regular shoes more slip-resistant? Ensure Safety with Proven Solutions

- Why is a lightweight design important for chef shoes? Boost Endurance and Agility in the Kitchen

- How do non-slip soles in chef shoes enhance safety? Unlock the Engineering Behind Kitchen Grip

- What are the features of non-slip athletic sneakers? The Ultimate Guide to Traction & Performance

- Do slip-resistant shoes work on all types of spills? The Truth About Matching Shoes to Hazards

- What is the general importance of wearing slip-resistant shoes? Essential Safety for High-Risk Workplaces

- How do slip-resistant safety shoes prevent accidents in hotel catering? Mastering Kitchen Safety & Traction

- How do lightweight work shoes help staff focus on work? Boost Productivity & Reduce Fatigue