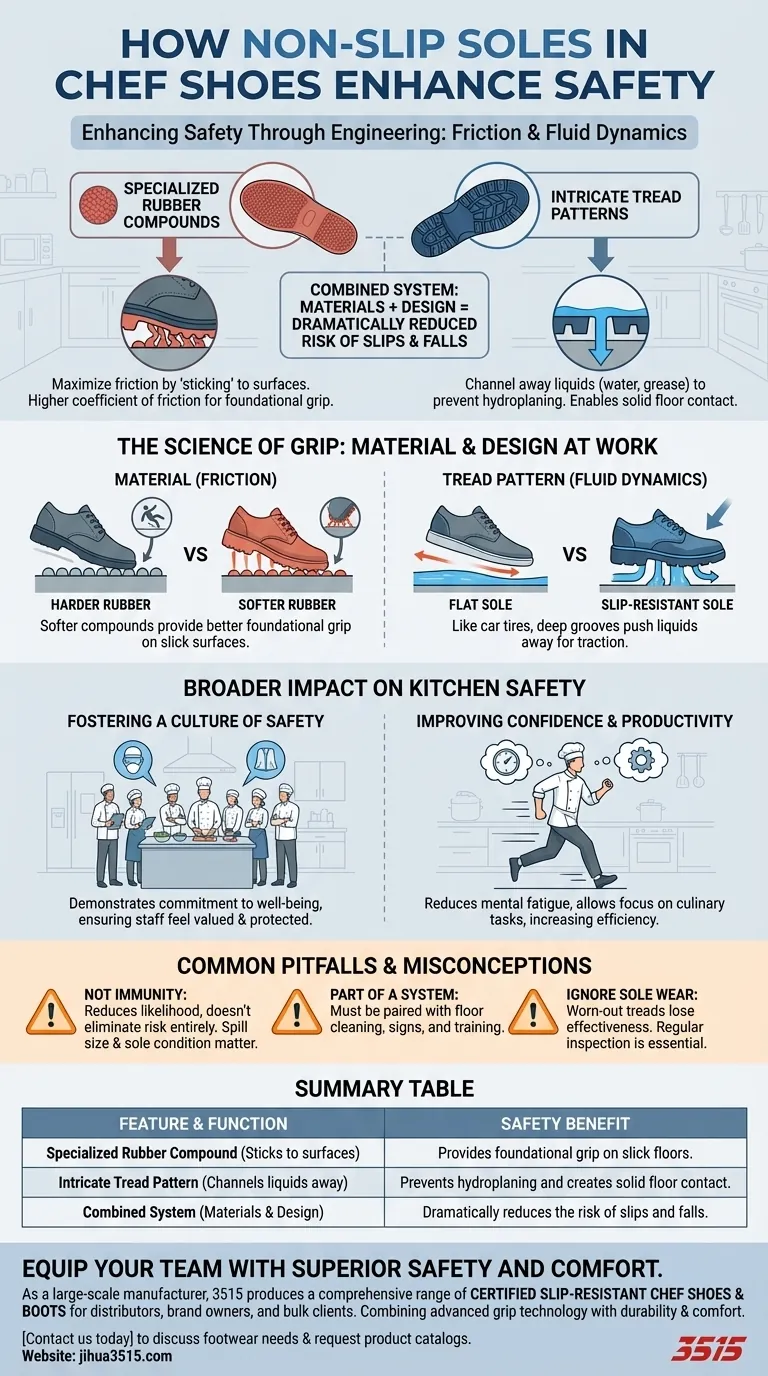

At their core, non-slip soles enhance safety through two critical design elements: specialized rubber compounds that maximize friction and intricate tread patterns that channel away liquids. This combination dramatically increases a chef's grip on the dangerously slick surfaces of a professional kitchen, directly reducing the risk of slips and falls.

The term "non-slip" is a bit of a misnomer; no shoe can completely defy physics. Instead, effective chef shoes are better understood as highly slip-resistant, engineered with specific materials and tread designs that work together to displace liquids and maximize friction on hazardous floors.

The Science of Grip: How a Slip-Resistant Sole Functions

To truly appreciate their safety value, you must understand that slip-resistant soles are an engineered system. The material and the design work in concert to solve a specific physics problem: maintaining traction when a low-friction liquid like water or grease is introduced.

The Critical Role of Material

The foundation of a good non-slip sole is its material composition. Most are made from high-quality, softer rubber compounds.

This choice is deliberate. Softer rubber has a higher coefficient of friction, meaning it is better at "sticking" to a surface at a microscopic level, providing a foundational layer of grip that harder materials lack.

The Engineering of the Tread Pattern

The tread is where the visible engineering takes place. Unlike the flat bottoms of casual shoes, slip-resistant soles feature complex, deep grooves and channels.

These patterns are not for style; they are for fluid dynamics. When you step on a wet or greasy patch, the liquid is instantly squeezed into these channels and pushed away from the bottom of the sole.

Creating Maximum Surface Contact

The tread pattern’s primary job is to clear a path. By channeling liquids away, it allows the specialized rubber material to make direct, solid contact with the floor.

This is the same principle behind the treads on a car tire, which prevent hydroplaning by pushing water out from under the tire. In the kitchen, the sole prevents "skating" on a thin film of oil or water.

Understanding the Broader Impact on Safety

The benefit of slip-resistant footwear extends beyond simply preventing a fall. It contributes to a safer and more efficient kitchen environment as a whole.

Fostering a Culture of Safety

Providing proper personal protective equipment (PPE), including slip-resistant shoes, demonstrates a commitment to employee well-being. This fosters a stronger safety culture where staff feel valued and protected.

Improving Confidence and Productivity

When chefs can move with confidence, they can work more efficiently and securely. They are not constantly second-guessing their footing, which reduces mental fatigue and allows them to focus on their culinary tasks.

Common Pitfalls and Misconceptions

True expertise requires understanding a tool's limitations. While highly effective, slip-resistant shoes are not a magic bullet, and believing they are can lead to a false sense of security.

"Non-Slip" Means Resistance, Not Immunity

The most critical point to understand is that these shoes reduce the likelihood of slipping; they cannot eliminate the risk entirely. A large spill, a poorly maintained floor, or a worn-out sole can still lead to an accident.

Forgetting the Rest of the Safety System

Slip-resistant shoes are only one part of a comprehensive kitchen safety program. They must be paired with diligent floor cleaning protocols, "wet floor" signs, and proper training on how to navigate potential hazards.

Ignoring Sole Wear and Tear

The effectiveness of a slip-resistant sole degrades over time. As the soft rubber wears down, the tread pattern becomes shallower and less effective at channeling liquids. Regular inspection and replacement are essential for maintaining safety.

How to Apply This to Your Kitchen

Choosing the right shoe means matching its features to your specific environment and priorities.

- If your primary focus is maximum safety in high-spill areas: Prioritize shoes with deep, complex tread patterns specifically rated for both oily and wet surfaces.

- If your primary focus is comfort during long shifts: Look for a certified slip-resistant sole combined with features like cushioned insoles, arch support, and lightweight construction.

- If your primary focus is long-term value: Investigate the specific rubber compound used, as some are designed to better resist degradation from cleaning chemicals and constant use.

Ultimately, understanding the engineering behind a slip-resistant sole empowers you to choose a tool that truly enhances safety in the demanding kitchen environment.

Summary Table:

| Feature | Function | Safety Benefit |

|---|---|---|

| Specialized Rubber Compound | Maximizes friction by 'sticking' to surfaces | Provides foundational grip on slick floors |

| Intricate Tread Pattern | Channels water, grease, and other liquids away | Prevents hydroplaning and creates solid floor contact |

| Combined System | Materials and design work together | Dramatically reduces the risk of slips and falls |

Equip your team with superior safety and comfort.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant chef shoes and boots for distributors, brand owners, and bulk clients. Our footwear combines advanced grip technology with the durability and comfort needed for long, demanding shifts.

We can help you enhance kitchen safety, boost staff confidence, and reduce workplace accidents. Contact us today to discuss your footwear needs and request product catalogs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What additional features do slip-resistant shoes often include for comfort? Beyond Grip for All-Day Wear

- What makes slip-resistant shoes essential for food service or industrial jobs? Prevent Costly Slips & Falls

- Why are standardized anti-slip work shoes required in biomechanical research? Ensuring Data Accuracy in Slip Studies

- How can you identify if shoes are non-slip? A Guide to Sole Material, Tread, and Safety

- What is the difference between oil resistance and slip resistance in footwear? Protect Your Boots and Your Safety

- What supplementary protection do portable anti-slip devices offer? Enhance Professional Footwear on Polished Snow

- What is the GRIP rating scheme for slip-resistant footwear? A Clear Guide to Workplace Safety

- Do slip-resistant shoes work on all types of spills? The Truth About Matching Shoes to Hazards