Applying boot wax is a simple process of working warmed wax into clean, dry leather with a cloth, paying special attention to seams. After the wax is absorbed and has dried, you buff off any excess to create a durable, water-resistant barrier. This method is most effective for full-grain, oiled, or previously waxed leather boots.

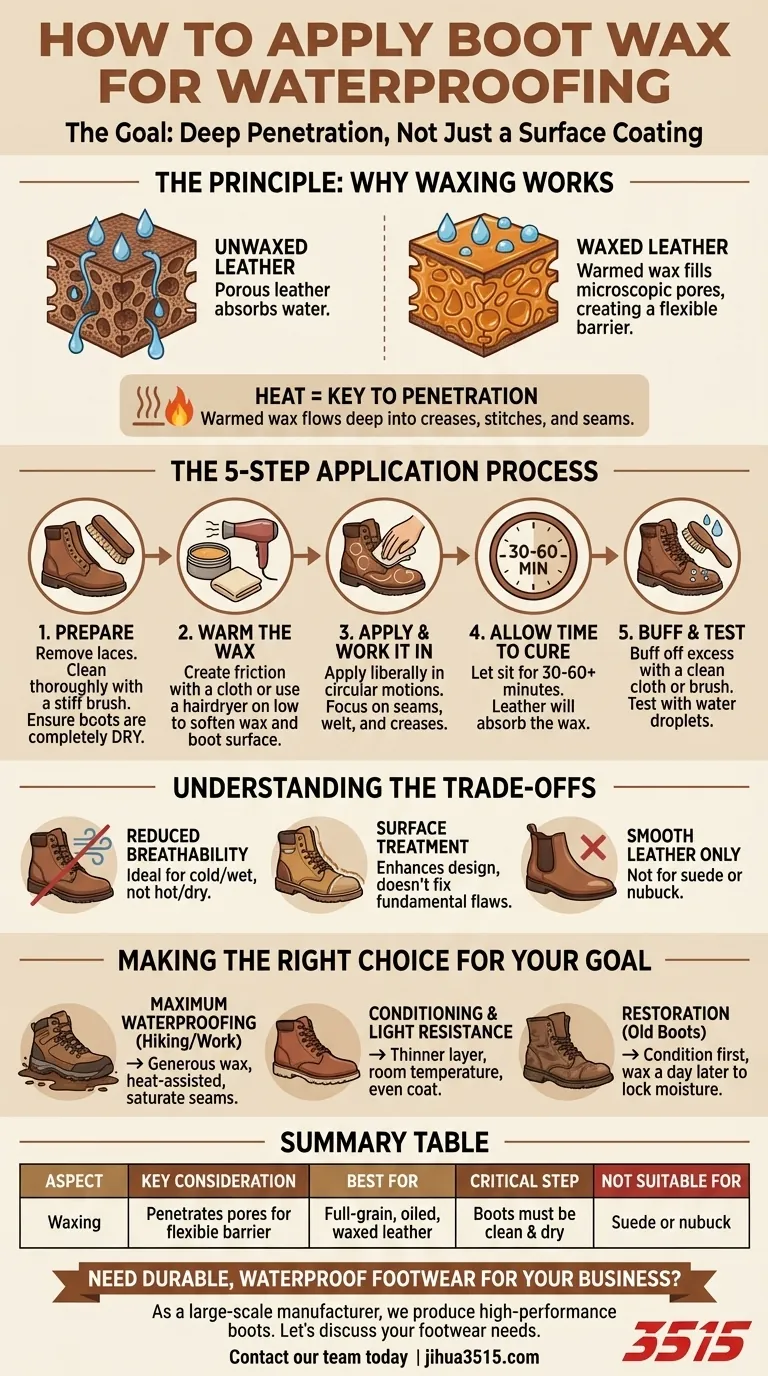

The goal of waxing is not to simply coat the boot's surface, but to allow the warmed wax to penetrate and seal the leather's natural pores. This creates a deep, flexible barrier against moisture from the inside out.

The Principle: Why Waxing Creates a Durable Seal

How Wax Protects Leather

Boot wax, typically made from beeswax, works by filling the microscopic pores inherent in natural leather. When warmed, the wax becomes less viscous, allowing it to soak deep into the material rather than just sitting on top. As it cools, it solidifies, creating a resilient and flexible barrier that repels water.

The Importance of a Clean Canvas

Applying wax to a dirty boot is ineffective. Dirt, dust, and grime clog the leather's pores, physically blocking the wax from penetrating. Always start with boots that are thoroughly cleaned and completely dry to ensure maximum absorption and a proper seal.

Heat is the Key to Penetration

Heat is the critical factor that transforms a simple coating into a deep-penetrating treatment. Gently warming the wax, and sometimes the boot itself with a hairdryer on a low setting, allows the wax to flow into every crease, stitch hole, and seam. This ensures the most vulnerable areas are fully protected.

The Step-by-Step Application Process

Step 1: Prepare the Boot

First, remove the laces to ensure you can access the tongue and all hidden seams. Use a stiff brush to remove all loose dirt and mud. If necessary, use a dedicated leather cleaner and a damp cloth to remove any stubborn grime, then allow the boots to air dry completely, away from direct heat.

Step 2: Warm the Wax

You can warm the wax simply by rubbing a clean cloth firmly in the tin to create friction. For a deeper application, you can use a hairdryer on a low setting to gently soften the surface of the wax in the tin or to warm the surface of the boot leather itself.

Step 3: Apply and Work It In

Using a clean, lint-free cloth or even your fingers, apply the wax in small, circular motions. Apply a liberal amount, ensuring you create an even layer over the entire boot. Pay special attention to the welt (where the sole joins the boot), all seams, and any high-flex creases.

Step 4: Allow Time to Cure

Let the boots sit for at least 30-60 minutes, or as directed by the product instructions. This curing time allows the wax to be fully absorbed by the leather. The leather will absorb what it needs, leaving a slight excess on the surface.

Step 5: Buff and Test

Using a clean cloth or a horsehair brush, buff the entire boot to remove the excess wax. This will remove the tacky feeling and can produce a slight sheen. To test your work, sprinkle a few drops of water on the boot; if it beads up and rolls off, your seal is effective.

Understanding the Trade-offs

Wax Reduces Breathability

The very process that makes wax effective—filling the leather's pores—also reduces the material's natural breathability. For this reason, wax is ideal for cold, wet conditions but may feel overly warm in hot, dry climates.

Wax is Only a Surface Treatment

While highly effective, wax is a maintenance treatment applied to the exterior leather. It cannot fix fundamental design flaws. A boot with a non-waterproof sole attachment or without a waterproof liner can still leak, even with a perfect wax coating. Wax enhances the boot's design; it does not replace it.

Compatibility with Leather Types

Wax is designed specifically for smooth, full-grain, or oiled leathers. It should not be used on suede or nubuck, as it will mat the fibers and permanently ruin the texture. Always use products specifically formulated for those materials.

Making the Right Choice for Your Goal

- If your primary focus is maximum waterproofing for hiking or work: Use a heat-assisted application with a generous amount of wax, ensuring every seam and the entire welt are completely saturated.

- If your primary focus is conditioning and light water resistance for casual boots: Apply a thinner layer of wax at room temperature, focusing more on achieving an even coat to nourish the leather than on saturating the seams.

- If your primary focus is restoring old, dry boots: Treat them with a dedicated leather conditioner first to restore oils and flexibility, then apply wax a day later to lock in that moisture and add a protective layer.

Properly waxing your boots is the most reliable way to take control of your gear's performance and longevity.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Best For | Full-grain, oiled, or previously waxed leather boots |

| Core Principle | Warm wax penetrates leather pores to create a flexible, internal barrier |

| Critical Step | Boots must be clean and completely dry before application |

| Primary Trade-off | Excellent waterproofing at the cost of reduced breathability |

| Not Suitable For | Suede or nubuck leathers |

Need Durable, Waterproof Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear, including rugged boots designed for superior waterproofing from the start.

We can help you:

- Source or customize boots with factory-applied, durable water repellent (DWR) treatments.

- Ensure critical seams and welts are constructed for maximum weather resistance.

- Provide consistent quality and volume for your brand or distribution network.

Let's discuss your footwear needs. Contact our team today to explore how we can build a reliable supply partnership.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

People Also Ask

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- What is the primary function of industrial safety shoes in polymer recycling? Protect Against Machinery & Sharp Debris

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- Why is hydrophobic waterproof leather commonly utilized in the construction of fire safety boots? Essential Protection

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards