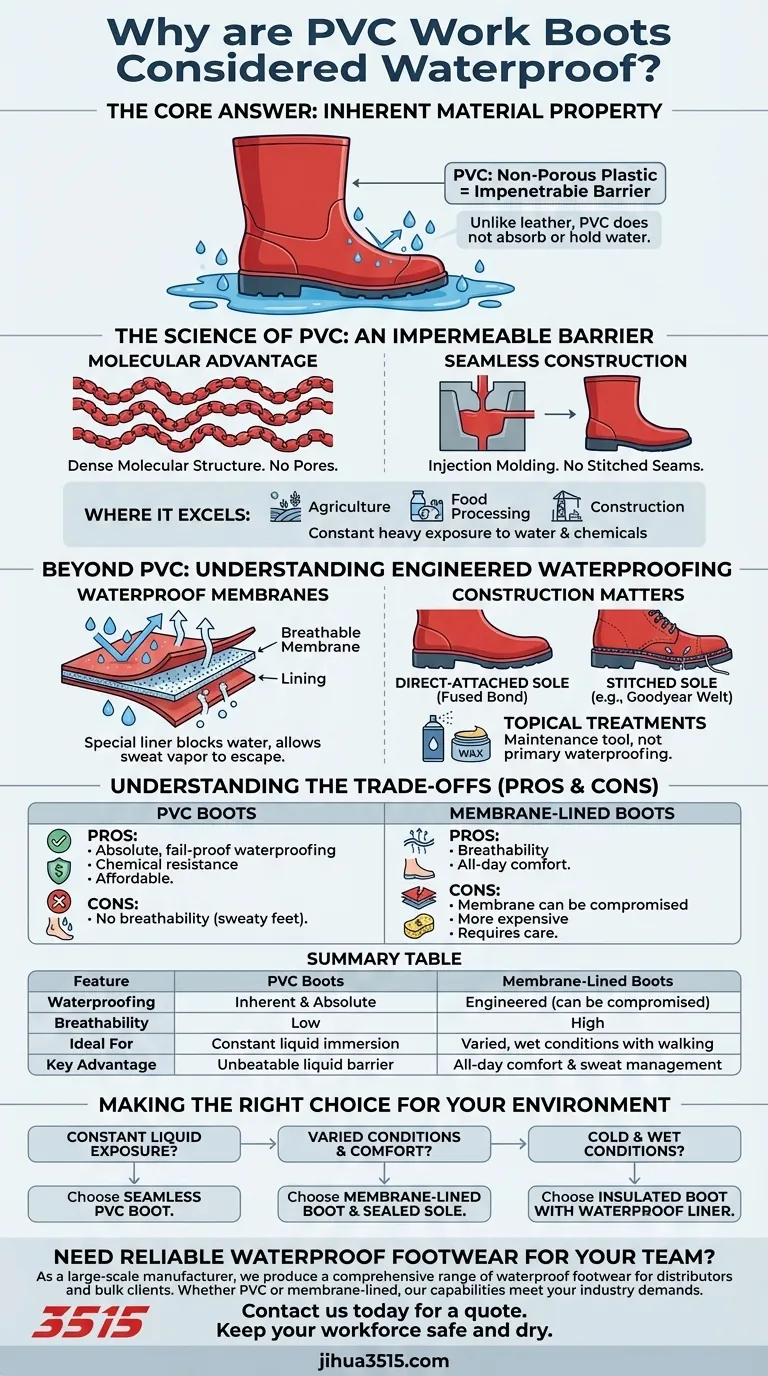

At a fundamental level, PVC work boots are considered waterproof because the material itself, polyvinyl chloride (PVC), is a non-porous plastic. Unlike natural materials like leather, PVC does not absorb or hold water, creating a solid, impenetrable barrier that keeps feet completely dry from external moisture.

While PVC offers absolute waterproofing due to its material properties, understanding the distinction between an inherently waterproof boot and an engineered waterproof boot is critical for selecting the right protection for your specific work environment.

The Science of PVC: An Impermeable Barrier

The reason PVC is so effective against water lies in its molecular structure and the way boots are manufactured from it. It is not a feature that is added; it is a core property of the material.

The Molecular Advantage

PVC is a polymer, a synthetic plastic made of long, tightly packed molecular chains. This dense structure leaves no microscopic pores for water molecules to seep through. The material simply cannot get saturated with water.

Seamless Construction

Most PVC work boots are created using an injection molding process. This means the entire boot, or at least the entire lower portion, is often formed as a single, seamless piece. This eliminates stitched seams, which are the most common points of failure for water entry in traditional leather or fabric boots.

Where Inherent Waterproofing Excels

This type of absolute, built-in waterproofing makes PVC boots the standard choice for industries with constant and heavy exposure to water, chemicals, and other liquids. This includes professions in agriculture, food processing, construction, and plumbing where feet are frequently submerged or splashed.

Beyond PVC: Understanding Engineered Waterproofing

While PVC is inherently waterproof, other types of work boots achieve water protection through design and technology. This is known as engineered waterproofing.

The Role of Waterproof Membranes

Many modern leather and synthetic boots feature a waterproof, breathable membrane. This is a special liner, or "bootie," built between the outer material and the inner lining. This membrane has pores that are too small for liquid water to pass through but large enough to allow water vapor (sweat) to escape, keeping feet dry from both the outside and inside.

The Importance of Construction

How the sole is attached to the boot upper is critical. A direct-attached sole that is fused to the upper creates a powerful waterproof bond. In contrast, a stitched sole, such as a Goodyear welt, requires special waterproof stitching and seals to prevent water from seeping in through the thread holes.

Topical Treatments and Their Limits

Waterproofing products like waxes and sprays are best seen as a maintenance tool, not a primary waterproofing method. They help maintain the water resistance of materials like leather and can seal minor weak spots, but they will not make a non-waterproof boot fully impervious to moisture.

Understanding the Trade-offs

Choosing between PVC and an engineered waterproof boot involves weighing the pros and cons of each technology against the demands of your job.

PVC Boots: Pros & Cons

The primary advantage of PVC is its absolute, fail-proof waterproofing and high chemical resistance at an affordable price. However, its main drawback is a complete lack of breathability. This can cause feet to sweat significantly, leading to discomfort over a long workday.

Membrane-Lined Boots: Pros & Cons

The key benefit of a boot with a waterproof membrane is breathability, which dramatically improves all-day comfort. The trade-off is that the membrane can be punctured or damaged, compromising its waterproof integrity. These boots are also typically more expensive and require more care to maintain the performance of the outer material.

Making the Right Choice for Your Environment

Your decision should be guided by your daily tasks and the conditions you face most often.

- If your primary focus is maximum protection from constant liquid exposure: Choose a seamless PVC boot. Its inherent waterproof nature is the most reliable defense for industries like food processing or heavy-duty cleaning.

- If your primary focus is all-day comfort in varied wet conditions: A boot with a waterproof membrane and sealed sole construction is the superior choice for roles requiring extensive walking, like a utility worker or landscaper.

- If your primary focus is working in cold and wet conditions: Select an insulated boot that explicitly states it has a waterproof liner or membrane to ensure your feet remain both warm and dry.

Ultimately, choosing the right boot is about matching the waterproofing technology to the reality of your work.

Summary Table:

| Feature | PVC Boots | Membrane-Lined Boots |

|---|---|---|

| Waterproofing | Inherent & Absolute | Engineered (can be compromised) |

| Breathability | Low | High |

| Ideal For | Constant liquid immersion | Varied, wet conditions with walking |

| Key Advantage | Unbeatable liquid barrier | All-day comfort & sweat management |

Need Reliable Waterproof Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof footwear for distributors, brand owners, and bulk clients. Whether you need the absolute protection of PVC or the advanced comfort of membrane-lined boots, our production capabilities cover all types of safety footwear to meet your specific industry demands.

Contact us today for a quote and let us provide durable, high-performance boots that keep your workforce safe and dry.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the pros of Stitch-down Construction? Unmatched Durability & Support for Your Boots

- What is a toe rand, and why is it optional? A Guide to Boot Durability

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Why is measuring both foot length and width important for boot fitting? Avoid Costly Foot Pain

- What workplace hazards do safety toe boots protect against? Comprehensive Protection Guide

- How can scratches on work boots be treated? A Guide to Restoring and Protecting Your Gear

- What features should a work boot have for a DIY mechanic? Essential Protection for Your Garage

- Why are heavy-duty work boots considered essential protective equipment? Safeguard Your Team on Hazardous Sites