Investing in quality work boots is only the first step. To truly maximize their lifespan from the very start, you must select the right boot for your specific job, ensure a perfect fit to prevent premature wear, break them in properly before heavy use, and apply a protective treatment like waterproofing or oil before their first day on the job.

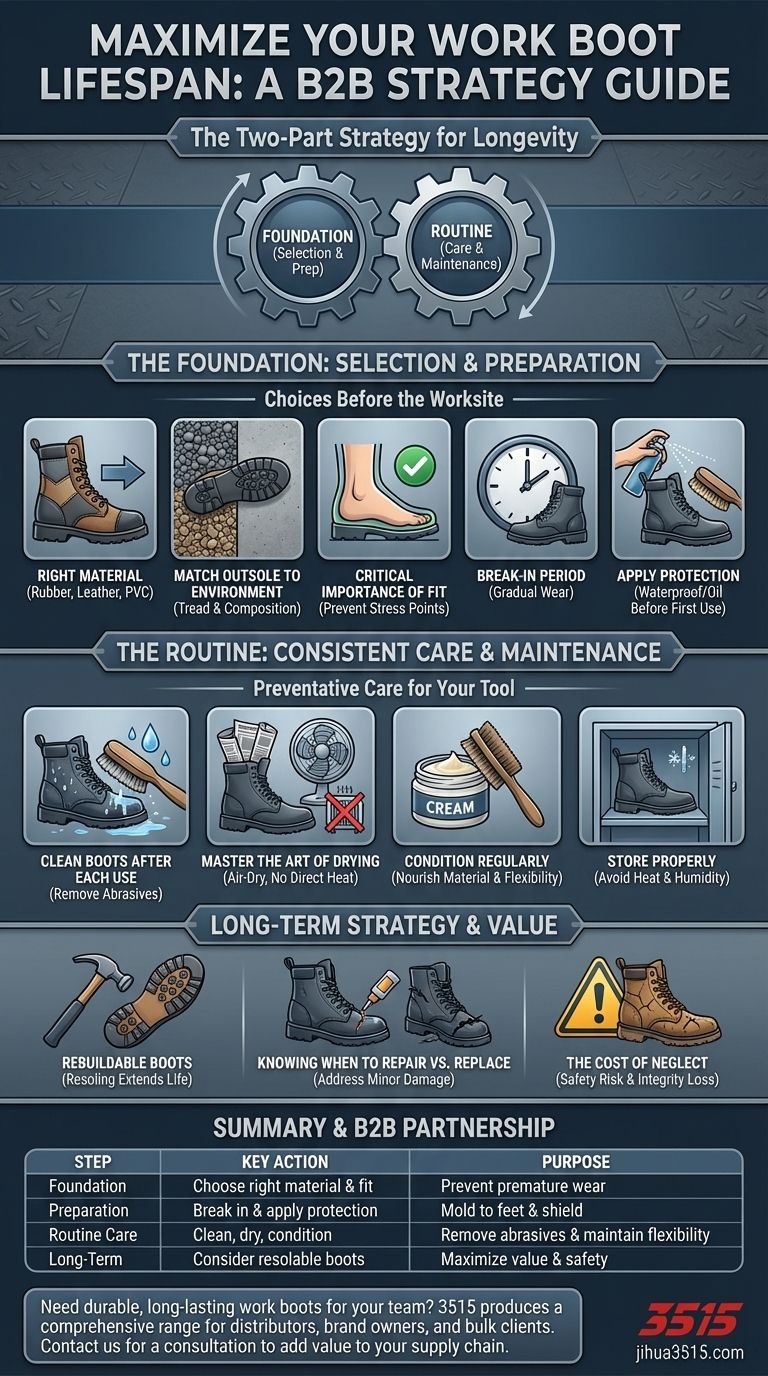

The longevity of your work boots is determined by a two-part strategy. Your initial selection and preparation set the foundation, but it is the consistent routine of cleaning, conditioning, and proper storage that dictates their ultimate lifespan.

The Foundation: Choosing and Preparing Your Boots

The choices you make before your boots ever touch a worksite have the most significant impact on their durability. Rushing this stage often leads to premature failure and replacement costs.

Start with the Right Material

The material must match your environment. Vulcanized rubber offers the highest resistance to wear and tear, making it ideal for harsh conditions. Leather is durable but requires conditioning, while materials like PVC and neoprene are better suited for less demanding jobs where tears are less likely.

Match the Outsole to the Environment

The outsole is your primary point of contact with the ground. A boot designed for a smooth concrete floor will wear out rapidly on abrasive gravel or dirt. Ensure the tread pattern and material composition are appropriate for your typical work surface.

The Critical Importance of Fit

A poor fit does more than cause discomfort. It creates unnatural stress points on the boot's seams and materials as your foot shifts inside. This constant friction and flexing leads to accelerated breakdown of the boot's structure.

The Break-In Period is Non-Negotiable

Never wear brand-new boots for a full workday. Wear them for a few hours at a time over several days. This allows the leather and structural components to mold to the specific shape of your feet, preventing concentrated stress and future blowouts.

Apply Protection Before First Use

Treat your boots before they are exposed to the elements. For leather boots, this means applying a quality waterproofing treatment or oil to nourish the leather and protect the seams. For rubber boots, a wax polish can provide a protective barrier against UV degradation.

The Routine: Consistent Care and Maintenance

Once your boots are in service, a simple and consistent maintenance routine is the key to preserving them. Think of it as preventative care for a critical tool.

Clean Boots After Each Use

A quick wipe-down or brushing at the end of the day is crucial. This removes abrasive materials like gravel, dirt, and chemicals that can slowly grind away at materials and stitching if left to sit.

Master the Art of Drying

Never use direct heat sources like heaters, radiators, or open flames to dry your boots. This can cause leather to crack and adhesives to fail. Stuff them with newspaper to absorb moisture and let them air-dry naturally, away from direct sunlight.

Condition the Material Regularly

Materials need to be nourished to stay flexible and strong. Leather boots should be conditioned monthly to keep the hide supple and prevent cracking. Even natural rubber boots benefit from a conditioner to maintain flexibility and prevent UV damage.

Store Them Properly

When not in use, keep your boots in a cool, dry place. Proper storage prevents the growth of mildew and protects the materials from the damaging effects of heat and humidity, which can degrade glues and synthetic components over time.

Understanding the Trade-offs and Long-Term Strategy

Investing in longevity means thinking beyond the initial purchase price and considering the boot's entire lifecycle.

The Value of Rebuildable Boots

Some high-quality boots are designed to be rebuilt. This means the outsole can be completely replaced by a cobbler when it wears out. Resoling a boot is significantly cheaper than buying a new pair and can extend its life for many years.

Knowing When to Repair vs. Replace

Address minor damage immediately. Small cuts or separating seams can often be fixed with specialty products like shoe glue, preventing them from becoming catastrophic failures. However, if the core structure or safety features are compromised, the boot must be replaced.

The Cost of Neglect

Failing to maintain your boots isn't just a financial mistake; it's a safety risk. Dried-out, cracked leather offers less protection, and failing seams compromise waterproofing and structural integrity, putting you at risk of injury and exposure.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your work environment and priorities.

- If your primary focus is working in wet or chemical-heavy environments: Prioritize boots made of vulcanized rubber or those with meticulously waterproofed seams, and re-apply treatments regularly.

- If your primary focus is durability in abrasive, high-wear conditions: Invest in high-quality leather boots that are resolable and make a habit of cleaning and conditioning them to combat the harsh environment.

- If your primary focus is maximizing lifespan with minimal daily effort: Establish the simple, non-negotiable habit of cleaning your boots and letting them air-dry after every single shift.

Treating your work boots as a critical piece of equipment, not just apparel, is the key to ensuring their long-term performance and protection.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| Foundation | Choose the right material & fit | Prevent premature wear and structural stress |

| Preparation | Break in boots & apply protective treatment | Mold boots to feet and shield from elements |

| Routine Care | Clean, dry naturally, and condition regularly | Remove abrasives and maintain material flexibility |

| Long-Term | Consider resolable boots & timely repairs | Maximize value and safety over the boot's lifecycle |

Need durable, long-lasting work boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, built with the durability and features discussed in this article. Let us help you equip your workforce with reliable footwear that stands up to the toughest conditions. Contact us today for a consultation and see how we can add value to your supply chain.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What features should be considered when choosing work boots for women? Essential Guide for Safety & Comfort

- What materials are typically used for the outsole of light work boots? Find the Perfect Balance of Durability & Comfort

- How can new work boots be broken in? A Step-by-Step Guide to a Pain-Free Fit

- What is the historical origin of moc toe boots? An American Industrial Legacy

- What practical features made engineer boots popular with workers? The Ultimate Guide to Industrial Safety Footwear

- Are there cowboy boots designed specifically for women? Find the Perfect Fit for Your Foot & Style

- What is the difference between traditional cowboy boots and roper boots? Choose the Right Boot for Your Needs

- What should be prioritized when choosing work boots? The Ultimate Guide to Safety, Comfort & Durability