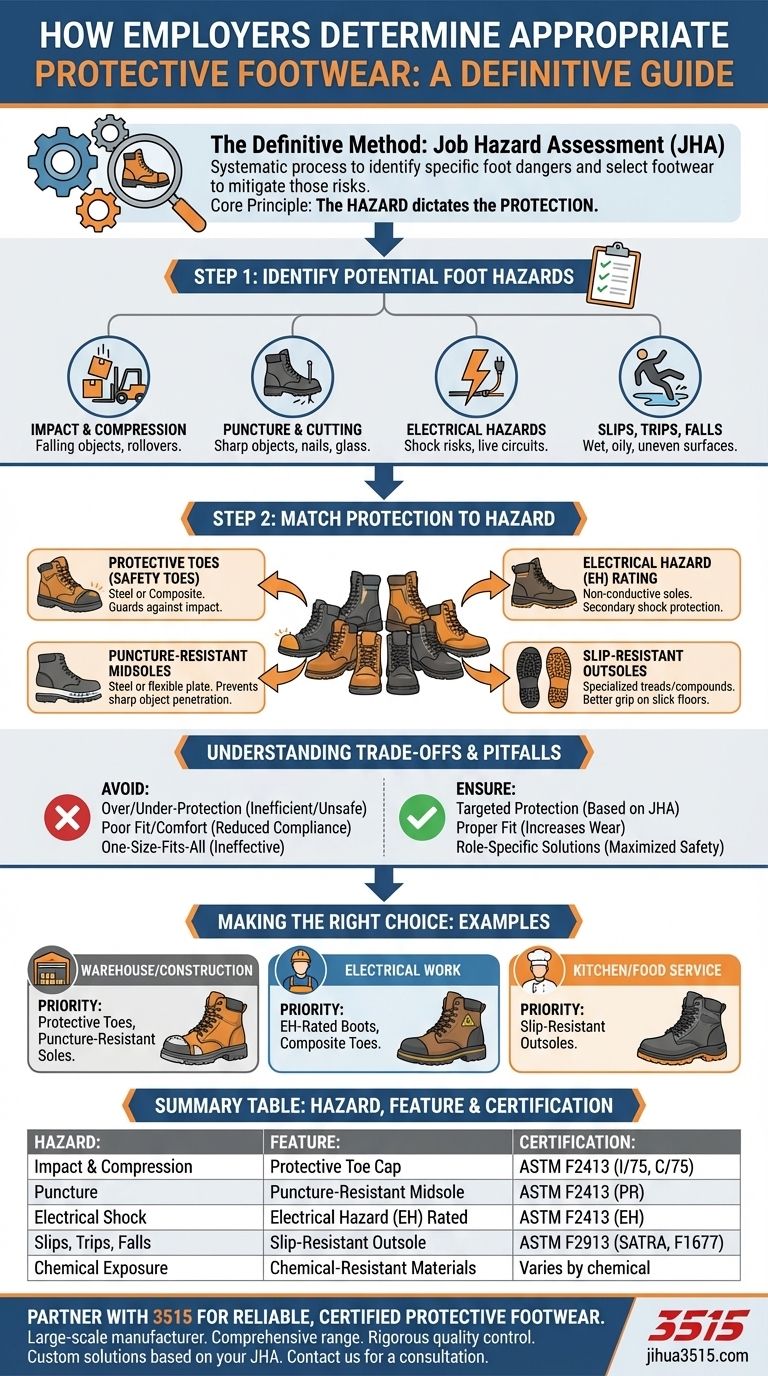

The definitive method for determining appropriate protective footwear is a formal Job Hazard Assessment (JHA). This systematic process involves carefully observing job tasks, identifying potential foot-related dangers in the work environment, and then selecting footwear specifically designed to mitigate those exact risks.

The core principle is simple: the hazard dictates the protection. Rather than searching for a "good work boot," employers must first identify specific risks like impact, puncture, or electrical shock, and then select footwear with the corresponding certified features.

The Foundation: The Job Hazard Assessment (JHA)

A Job Hazard Assessment is not a casual walkthrough. It is a structured process to proactively identify and control dangers before an incident occurs. For footwear, this means focusing on what could happen to an employee's feet during their daily tasks.

Step 1: Identify Potential Foot Hazards

The first step is to analyze every role and work area. You must document any specific and credible threats to foot safety.

Common hazards include:

- Impact and Compression: This involves risks from falling objects or rollovers from heavy equipment. Think of a heavy box falling off a shelf or a forklift running over a foot.

- Puncture and Cutting: This is the danger of sharp objects piercing the sole of a shoe, such as nails, scrap metal, or broken glass on a floor. Kitchens also present risks from dropped knives.

- Electrical Hazards: This applies to anyone working near live or potentially live electrical circuits. The risk is a dangerous or fatal electrical shock passing through the body.

- Slips, Trips, and Falls: Wet, oily, or uneven surfaces are among the most common workplace hazards, leading to serious injuries.

- Chemical Exposure: Certain chemicals can degrade footwear material or cause direct harm to the skin upon contact.

Step 2: Match the Protection to the Hazard

Once you have identified the hazards, you can select footwear with the correct protective features. These features are standardized and certified to meet specific safety criteria.

Understanding Key Footwear Features

- Protective Toes (Safety Toes): This is the most common feature. Steel toes are the traditional standard for impact and compression resistance. Composite toes (made of materials like Kevlar, carbon fiber, or plastic) offer similar protection but are lighter and do not conduct electricity.

- Puncture-Resistant Midsoles: Often made of steel or flexible woven fabrics, these plates are built into the sole to prevent sharp objects from penetrating the bottom of the foot.

- Electrical Hazard (EH) Rating: EH-rated boots are constructed with non-conductive, shock-resistant soles and heels. This feature is critical for electricians as it provides a secondary source of protection from electrocution.

- Slip-Resistant Outsoles: These soles are made from softer rubber compounds and feature specific tread patterns designed to channel away liquids and increase the surface contact area, providing better grip on wet or slick floors.

Understanding the Trade-offs and Common Pitfalls

Choosing the right footwear requires balancing protection with practicality. A mistake in either direction can compromise safety.

Over-Protection vs. Under-Protection

Mandating a heavy-duty, steel-toe, puncture-resistant boot for a role with only a slip hazard can be counterproductive. The footwear will be heavy and uncomfortable, potentially leading to non-compliance. Conversely, providing a simple slip-resistant shoe to a warehouse worker is a critical safety failure.

Forgetting About Comfort and Fit

Protective footwear only works if it's worn properly. Boots that are a poor fit or excessively uncomfortable are more likely to be modified by employees or not worn at all, completely negating their protective value.

Relying on a Single Solution

A single facility may require multiple types of protective footwear. The needs of a maintenance electrician are fundamentally different from those of a forklift operator or a kitchen staff member working in the same building. A one-size-fits-all policy rarely works.

Making the Right Choice for Your Environment

Your final decision should be guided by the specific, documented risks of the job role.

- If your primary focus is a warehouse or construction site: Prioritize footwear with certified protective toes (steel or composite) and puncture-resistant soles to guard against impact and sharp debris.

- If your primary focus is electrical work: Mandate boots with a certified Electrical Hazard (EH) rating and composite (non-conductive) toes.

- If your primary focus is a kitchen, food service, or medical environment: Specify footwear with certified slip-resistant outsoles as the top priority, with puncture resistance as a secondary consideration if needed.

Ultimately, selecting the right protective footwear is a direct outcome of a thoughtful and thorough safety assessment.

Summary Table:

| Hazard Type | Recommended Footwear Feature | Key Certifications/Standards |

|---|---|---|

| Impact & Compression | Protective Toe Cap | ASTM F2413 (I/75 or I/50 for impact; C/75 or C/50 for compression) |

| Puncture | Puncture-Resistant Midsole | ASTM F2413 (PR) |

| Electrical Shock | Electrical Hazard (EH) Rated | ASTM F2413 (EH) |

| Slips, Trips, Falls | Slip-Resistant Outsole | ASTM F2913 (SATRA, F1677 Mark II) |

| Chemical Exposure | Chemical-Resistant Materials | Varies by chemical (e.g., Neoprene, Nitrile rubber) |

Need reliable, certified protective footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety shoes and boots, designed to meet the specific hazards identified in your Job Hazard Assessment.

Partner with us to:

- Source with confidence from a manufacturer with rigorous quality control.

- Get the right fit for every role with our extensive product range.

- Ensure compliance and worker safety with certified protective features.

Contact 3515 today for a consultation and let us help you equip your workforce with the right protection.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?