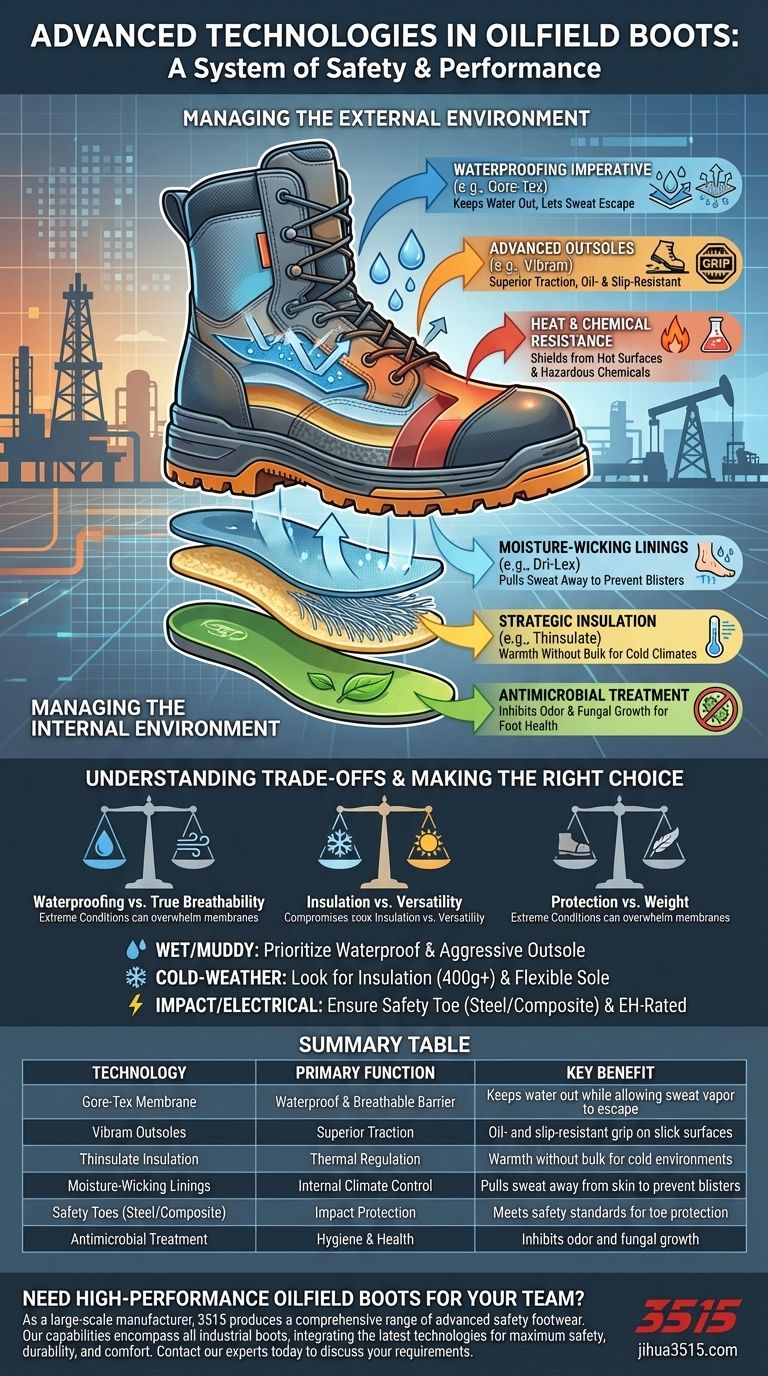

Modern oilfield boots integrate a suite of advanced technologies designed to provide a comprehensive system of safety, durability, and comfort. These innovations include waterproof yet breathable membranes like Gore-Tex, specialized outsole compounds from brands like Vibram for superior traction on slick surfaces, and high-performance insulation such as Thinsulate for thermal regulation. They also incorporate critical safety features like electrical hazard protection and materials engineered to resist heat and chemicals.

The most advanced oilfield boots are not defined by a single feature, but by how these individual technologies work together as a system to manage the extreme external environment while maintaining a safe and stable internal environment for your foot.

Managing the External Environment

The primary challenge in the oilfield is protecting you from the hazardous conditions on site. Modern boot technology creates a barrier against water, chemicals, and slippery surfaces.

The Waterproofing Imperative

A boot's ability to keep water out is fundamental. Technologies like Gore-Tex use a membrane with pores that are too small for liquid water molecules to penetrate from the outside.

Critically, these pores are large enough for smaller water vapor molecules (sweat) to escape from the inside. This creates a boot that is both waterproof and breathable, preventing external moisture while reducing internal sweat buildup.

The Foundation of Safety: Advanced Outsoles

Traction is a non-negotiable safety requirement. Brands like Vibram are leaders in this area, developing specialized rubber compounds, not just tread patterns.

These outsoles are engineered to be oil- and slip-resistant, preventing the chemical breakdown that can occur when standard rubber contacts petroleum products. This ensures the sole maintains its grip and integrity on slick rig floors and muddy terrain.

Heat and Chemical Resistance

Many boots also use materials in the sole and upper that are rated for high-heat resistance. This provides short-term protection against contact with hot surfaces or materials, preventing severe burns and sole degradation.

Managing the Internal Environment

Equally important is managing the climate inside the boot. Long shifts demand technologies that handle sweat, regulate temperature, and maintain hygiene to prevent discomfort and injury.

The Battle Against Moisture

Even with a breathable membrane, you will sweat. Linings made from materials like Dri-Lex are designed to be moisture-wicking.

They actively pull perspiration away from your skin and spread it across a larger surface area, allowing it to evaporate more quickly through the breathable membrane. This process is vital for preventing blisters and skin breakdown.

Regulating Temperature: Strategic Insulation

For work in colder climates, insulation is key. Materials like Thinsulate provide exceptional warmth without adding significant bulk or weight.

This is achieved using extremely fine microfibers that trap air, creating a thermal barrier. The lack of bulk ensures you maintain the flexibility and mobility needed to work effectively and safely.

Preventing Odor and Fungus

Long hours in boots can create a breeding ground for bacteria and fungus. Many high-end boots now include an antimicrobial treatment integrated into the footbed and lining to inhibit microbial growth, control odor, and improve overall foot health.

Understanding the Trade-offs

No single boot is perfect for every condition. Understanding the inherent compromises in boot technology is key to selecting the right tool for the job.

Waterproofing vs. True Breathability

Even the best waterproof/breathable membranes have limitations. In extremely hot and humid conditions, the rate of sweat production can overwhelm the membrane's ability to transfer moisture vapor, making the boot feel warm and damp.

Insulation vs. Versatility

A boot with heavy insulation (e.g., 600g Thinsulate or higher) is ideal for sub-zero work but will be extremely uncomfortable and cause excessive sweating in moderate or warm weather. Often, professionals require different boots for different seasons.

Protection vs. Weight

Features like steel toes, puncture-resistant plates, and thick, durable outsoles are critical for safety. However, they add weight and can reduce flexibility, leading to increased fatigue over a 12-hour shift. Lighter composite safety toes can mitigate this, but a balance must always be struck.

Making the Right Choice for Your Role

Selecting the right boot means matching the technology to your specific work environment and primary risks.

- If your primary focus is working in wet, muddy conditions: Prioritize a boot with a proven waterproof/breathable membrane and an aggressive, oil-resistant outsole.

- If your primary focus is cold-weather environments: Look for a boot with at least 400g of quality insulation and a sole compound that remains flexible in freezing temperatures.

- If your primary focus is safety from impact and electrical risks: Ensure your boot has a certified safety toe (steel or composite) and is explicitly EH-rated.

Ultimately, viewing your boots as a critical piece of performance equipment ensures you select the technology that will keep you safe and productive.

Summary Table:

| Technology | Primary Function | Key Benefit |

|---|---|---|

| Gore-Tex Membrane | Waterproof & Breathable Barrier | Keeps water out while allowing sweat vapor to escape |

| Vibram Outsoles | Superior Traction | Oil- and slip-resistant grip on slick surfaces |

| Thinsulate Insulation | Thermal Regulation | Warmth without bulk for cold environments |

| Moisture-Wicking Linings | Internal Climate Control | Pulls sweat away from skin to prevent blisters |

| Safety Toes (Steel/Composite) | Impact Protection | Meets safety standards for toe protection |

| Antimicrobial Treatment | Hygiene & Health | Inhibits odor and fungal growth |

Need High-Performance Oilfield Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of advanced safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial boots, integrating the latest technologies like those described above to ensure maximum safety, durability, and comfort for workers in the most demanding environments.

Let us help you equip your workforce with the right protective gear. Contact our experts today to discuss your specific requirements and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene