Deeper grooves on slip-resistant shoes improve safety by creating significantly more friction between the sole and the floor. These grooves, often called treads, act as channels that grip the walking surface, with each individual groove measurably increasing the shoe's hold and reducing the risk of a slip.

The core function of a slip-resistant shoe is not just to cover your foot, but to actively manage the point of contact with the ground. Deeper grooves are a critical engineering feature designed to maximize this contact and friction, especially when surfaces are compromised by liquids.

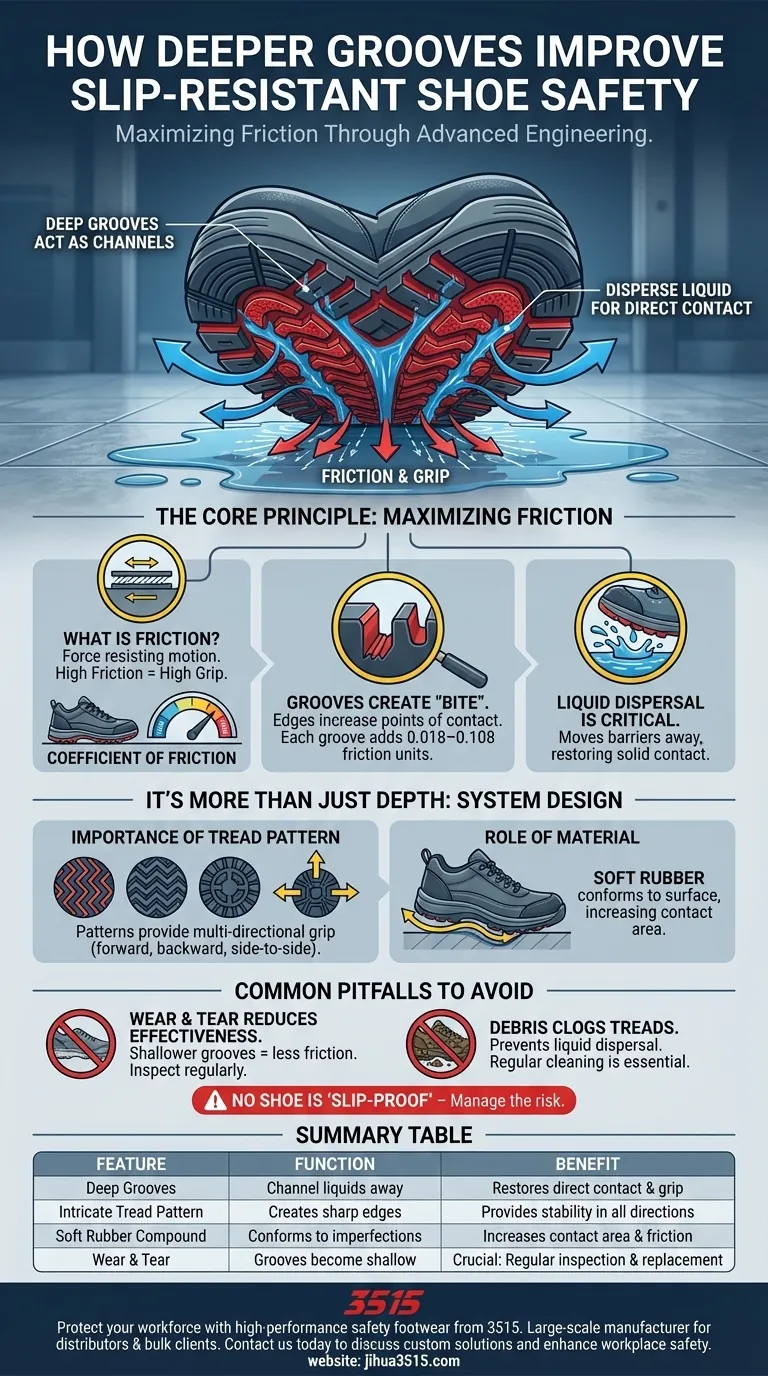

The Core Principle: Maximizing Friction

To understand slip resistance, we first need to understand the role of friction. It’s the force that resists motion when two surfaces rub against each other.

What Friction Means for Safety

In simple terms, high friction equals high grip. When you walk, the sole of your shoe rubs against the floor. A shoe with a higher coefficient of friction will be much harder to slide across that surface, providing a more stable footing.

How Grooves Create Friction

The deep grooves, or treads, on a shoe's outsole are designed to "bite" into the walking surface. The edges of these grooves create multiple points of contact that increase the overall resistance.

Each groove adds a measurable amount of friction—typically between 0.018 and 0.108 friction units, depending on the floor type. This is why a greater number of deep grooves generally corresponds to better slip resistance.

The Critical Role of Liquid Dispersal

On a wet or oily floor, the liquid creates a barrier between the shoe and the surface, which is a primary cause of slips. Deep grooves act as channels, quickly moving this liquid away from the bottom of the shoe.

This channeling allows the solid parts of the rubber sole to make direct contact with the floor, restoring the friction needed for a secure grip.

It's More Than Just Groove Depth

While depth is crucial, it's part of a larger system. The overall design of the outsole determines its effectiveness.

The Importance of Tread Pattern

The pattern of the grooves is also a key factor. Small, circular, or zigzag patterns create multiple sharp edges that can grip from any direction, providing stability whether you are moving forward, backward, or side-to-side.

The Role of Material

Most slip-resistant shoes use a soft rubber compound for the outsole. This material is naturally high in friction and is flexible enough to conform to the microscopic imperfections in a floor surface, further increasing the contact area and grip.

Common Pitfalls to Avoid

Even the best slip-resistant shoes have limitations. Understanding them is key to maintaining safety.

Wear and Tear Reduces Effectiveness

Over time, the tread on any shoe will wear down. As the grooves become shallower, their ability to channel liquids and create friction decreases significantly. A worn-out slip-resistant shoe is no longer a safety shoe.

Debris Can Clog the Treads

Deep grooves can sometimes become clogged with dirt, grease, or other debris. When this happens, the channels can no longer disperse liquid effectively, and the sole's contact with the floor is compromised. Regular cleaning is essential.

No Shoe is "Slip-Proof"

The term "slip-resistant" is important—no shoe is completely "slip-proof." These shoes dramatically reduce the risk of slips and falls, but extreme conditions or large spills can still overwhelm any footwear design.

Making the Right Choice for Your Goal

When selecting footwear, consider the specific environment where it will be used.

- If your primary focus is safety on wet or oily floors: Look for shoes with a high density of deep, intricate grooves designed to maximize liquid channeling.

- If your primary focus is stability across various indoor surfaces: A shoe with a multi-patterned tread and a soft rubber sole will provide versatile and reliable grip.

- If your primary focus is long-term safety: Remember that slip-resistance is a feature that wears out, so commit to regularly inspecting your shoe's treads and replacing them when they become worn.

Ultimately, choosing the right shoe is an active investment in your personal safety.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Deep Grooves | Channel liquids away from the sole | Restores direct contact with the floor |

| Intricate Tread Pattern | Creates multiple sharp edges for grip | Provides stability in all directions |

| Soft Rubber Compound | Conforms to floor imperfections | Increases contact area and friction |

| Wear & Tear | Grooves become shallower over time | Regular inspection and replacement are crucial |

Protect your workforce with high-performance safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our expertise in engineering outsoles with optimal groove depth and tread patterns ensures maximum grip and durability for your specific work environment. Contact us today to discuss your custom footwear needs and enhance workplace safety.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- Why is arch support important in work shoes? Protect Your Body from Fatigue and Pain

- What industries are most at risk for slips and falls at work? Protect Your Workforce and Bottom Line

- What is the objective of conducting comparative experiments on packed vs. polished snow? Optimize Anti-Slip Performance

- What is the most effective long-term solution for making shoes non-slip? Achieve Permanent Safety with Professional Resoling

- What are the benefits of slip-resistant shoes for women in the workplace? Prevent Costly Falls & Boost Productivity

- Why must a high-precision digital Shore hardness tester be used before evaluating footwear slip resistance performance?

- What are the advantages of visiting a cobbler for non-slip shoe solutions? Get a Professional, Durable Fix

- What combination of features prevents non-slip shoes from slipping? The Science of Sole Material, Tread, and Liquid Displacement