To enhance the water resistance of your boots, you must use a combination of topical treatments and understand your boot's structural features. The most effective methods involve applying products like wax, oil, or sprays to create a protective barrier while also leveraging physical elements like stitchdown construction and kilties to block water entry points.

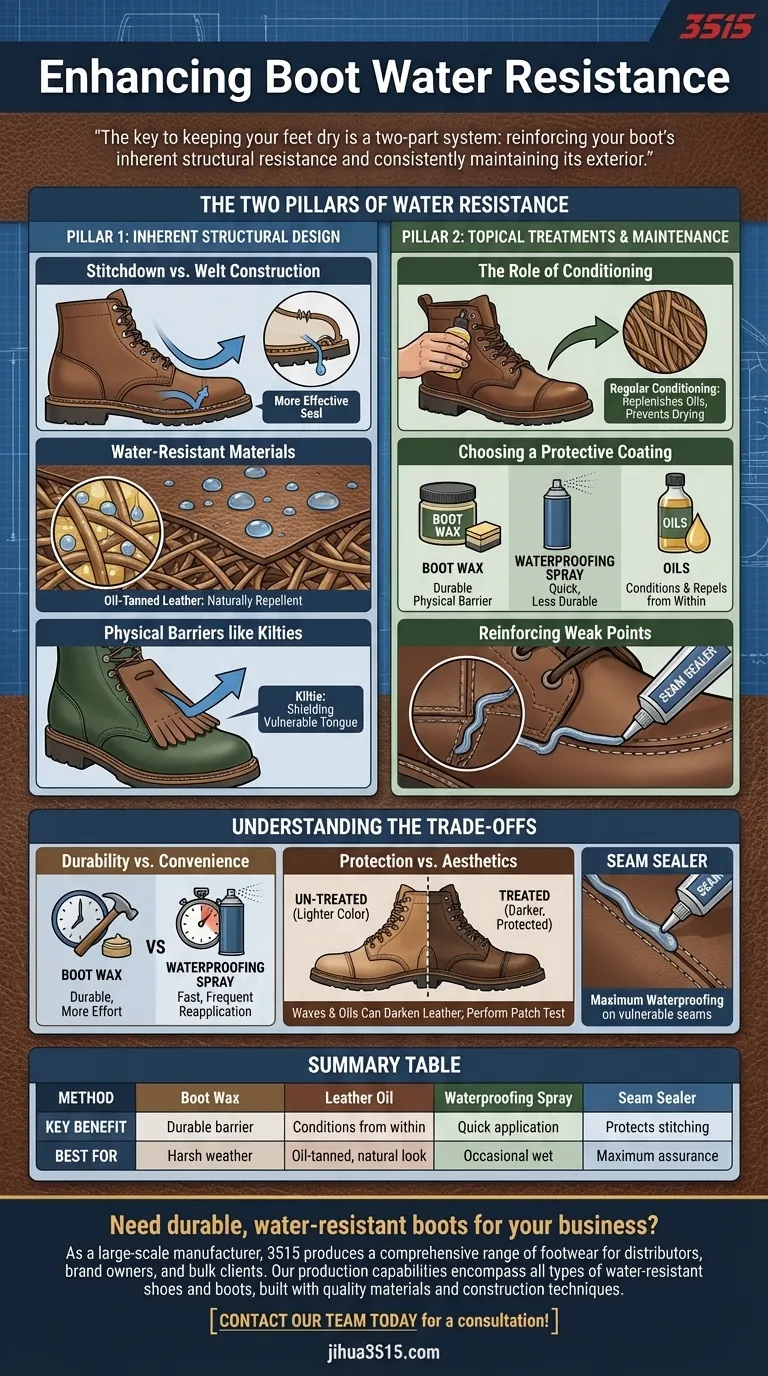

The key to keeping your feet dry isn't a single product, but a two-part system: reinforcing your boot's inherent structural resistance and consistently maintaining its exterior with the right protective treatment.

The Two Pillars of Water Resistance

True water resistance is achieved by addressing two distinct elements: the boot's fundamental construction and the treatments you apply to its surface. Understanding both is essential for effective protection.

Pillar 1: Inherent Structural Design

A boot's construction is its first line of defense against moisture.

Stitchdown vs. Welt Construction The way the upper is attached to the sole significantly impacts water resistance. Stitchdown construction, where the upper leather is turned outward and stitched to the midsole, creates a more effective seal against water compared to a Goodyear welt, which can sometimes allow moisture to seep in over time.

Water-Resistant Materials The material itself is critical. Oil-tanned leather is naturally highly water-repellent because its fibers are saturated with oils and waxes. This causes water to bead up and roll off rather than soak into the material.

Physical Barriers like Kilties A kiltie is a fringed leather panel placed under the laces, covering the tongue of the boot. While often seen as decorative, its primary function is to provide an extra layer of protection, shielding the vulnerable tongue and lace area from water, mud, and debris.

Pillar 2: Topical Treatments and Maintenance

Regularly applying a protective coating is crucial for maintaining and enhancing your boot's ability to repel water.

The Role of Conditioning Leather requires its natural oils to remain pliable and water-resistant. Regular conditioning, especially with leather oils, replenishes these oils, ensuring the leather doesn't dry out and begin absorbing moisture. This should be done monthly for boots exposed to harsh conditions.

Choosing a Protective Coating Different products offer different levels of protection. Boot wax provides a thick, durable physical barrier on the surface. Waterproofing sprays offer a quick but less durable chemical coating. Oils condition while adding water resistance from within the leather's fibers.

Understanding the Trade-offs

Selecting a waterproofing method involves balancing protection, appearance, and maintenance effort. There is no single "best" solution for every boot or situation.

Durability vs. Convenience

Boot wax offers the most durable and robust protection but requires more time and effort to apply correctly. Waterproofing sprays are extremely fast and easy to use but wear off quickly and require frequent reapplication to remain effective.

Protection vs. Aesthetics

Many effective treatments, particularly oils and waxes, can darken the leather. This change in appearance may be undesirable for certain styles of boots. It is critical to perform a patch test on a small, inconspicuous area first.

Reinforcing Weak Points

The seams are the most common points of failure for water entry. A seam sealer is a specialized product designed to be applied directly to the stitching, creating a flexible, waterproof seal that reinforces these vulnerable areas.

Making the Right Choice for Your Goal

Your ideal strategy depends on your specific needs and the type of conditions you anticipate facing.

- If your primary focus is maximum, long-lasting protection for harsh weather: Use a dedicated seam sealer on all stitching, followed by a thorough application of a heavy-duty boot wax.

- If your primary focus is maintaining the natural look of oil-tanned leather: Rely on regular monthly conditioning with a high-quality leather oil to replenish its inherent water-repellent properties.

- If your primary focus is quick and easy application for occasional wet weather: A waterproofing spray is a suitable choice, but be prepared to reapply it regularly.

Properly maintaining your boots not only keeps your feet dry and comfortable but also protects your investment for years to come.

Summary Table:

| Method | Key Benefit | Best For |

|---|---|---|

| Boot Wax | Durable, thick barrier | Harsh weather, long-term use |

| Leather Oil | Conditions & repels from within | Oil-tanned leather, natural look |

| Waterproofing Spray | Quick, easy application | Occasional wet conditions |

| Seam Sealer | Protects vulnerable stitching | Maximum waterproofing assurance |

Need durable, water-resistant boots for your business? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of water-resistant shoes and boots, built with quality materials and construction techniques. Let us help you source reliable footwear that meets your customers' needs. Contact our team today for a consultation!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How did Goodyear welt construction become more accessible? A History of Industrial Innovation

- How do integrated FSR in sensing insoles prevent diabetic foot ulcers? Smart Monitoring for Diabetic Foot Health

- What are synthetic materials in footwear, and how have they evolved? From Imitation to High-Performance Innovation

- How does the picture association technique provide insights into consumer preferences? Decode Footwear Psychology

- How should synthetic riding boots be cared for? A Guide to Long-Lasting Performance

- What are some additional tips for caring for cowboy boots? Essential Habits for Long-Lasting Boots

- What is the significance of peer-to-peer (P2P) online platforms in extending footwear lifecycle? Closing the Loop

- What data does a chest strap heart rate monitor provide? Unlock Footwear Cardiovascular Efficiency Insights