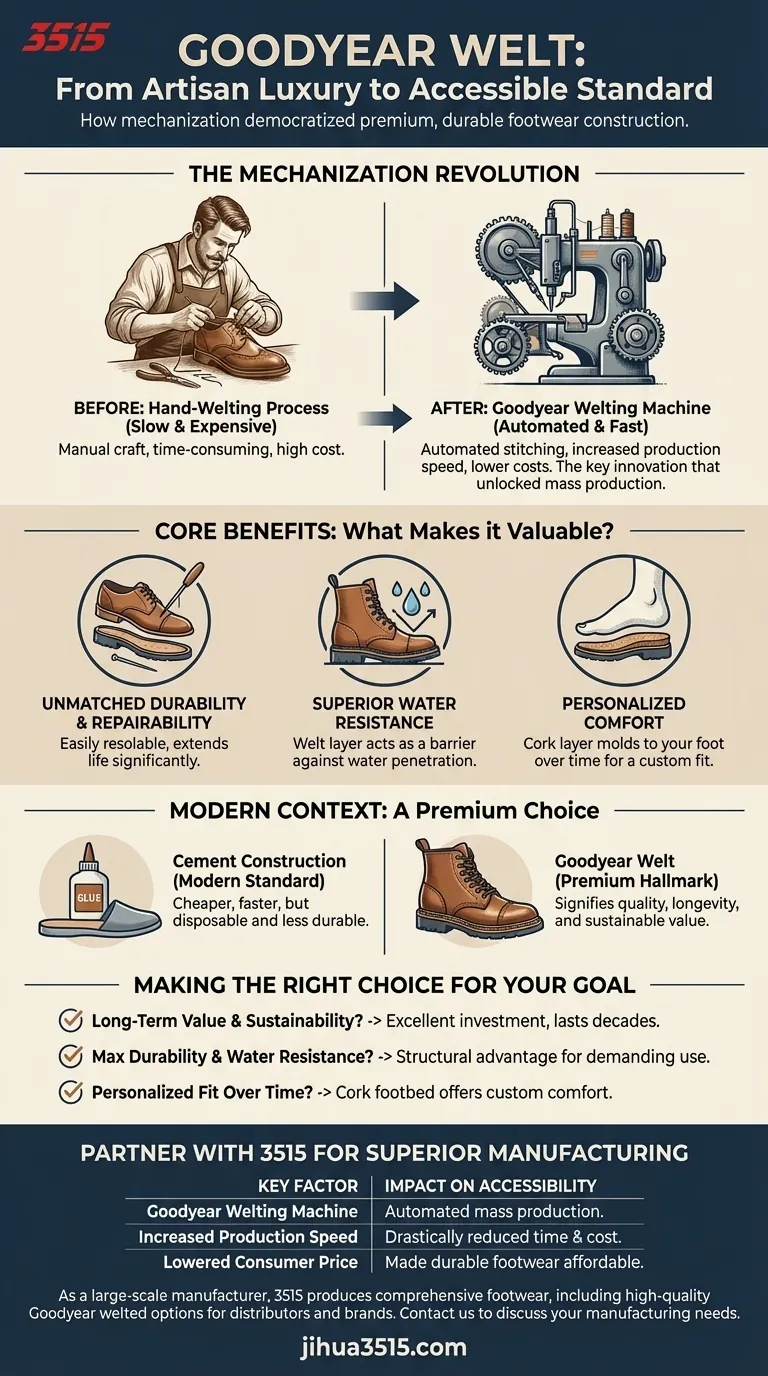

At its core, Goodyear welt construction became more accessible through mechanization. The invention of the Goodyear welting machine by Charles Goodyear Jr. in the 1860s automated what was previously a slow and expensive hand-sewn process, dramatically increasing production speed and lowering costs.

The crucial innovation was not the welt itself, but the machine that could replicate the work of a master craftsman at industrial speed. This single development transformed durable, repairable footwear from a luxury good into an achievable standard.

From Artisan Craft to Industrial Standard

To understand the impact of the Goodyear welting machine, you must first understand the process it replaced. It was a solution to the high cost and slow pace of traditional shoemaking.

The Original Hand-Welting Process

Before industrialization, creating a welted shoe was an exclusively manual craft. A skilled artisan would painstakingly stitch the shoe's upper, lining, and a leather strip (the welt) to the insole. This process was incredibly time-consuming, making the resulting footwear durable but prohibitively expensive for most people.

The Goodyear Innovation

Charles Goodyear Jr.'s machine automated this critical stitching step. It could rapidly and consistently attach the welt to the insole and upper, accomplishing in minutes what took a craftsman hours. This mechanization was the key that unlocked mass production for high-quality footwear.

The Impact of Mechanization

By automating the most labor-intensive part of the process, factories could produce welted shoes on a massive scale. By the mid-20th century, the Goodyear welting machine had become the standard for quality footwear production, making exceptionally durable shoes available to a broad market.

What Makes This Construction So Valued?

The accessibility of Goodyear welting was a historical shift, but the reasons it remains a premium feature today lie in its fundamental design benefits. It creates a shoe that is built to last and adapt to its owner.

Unmatched Durability and Repairability

The defining feature of a Goodyear welt is that the outsole is stitched to the welt, not directly to the upper. This means a cobbler can easily remove the old sole and attach a new one without compromising the shoe's structure. This simple resoling can be done multiple times, drastically extending the life of a single pair of shoes.

Superior Water Resistance

The welt acts as a barrier between the insole and the outsole. This extra layer, combined with the lockstitch seam, makes it significantly more difficult for water to penetrate the shoe from below compared to other construction methods.

The Path to Personalized Comfort

Between the insole and the outsole, a Goodyear welted shoe contains a layer of granulated cork. As you wear the shoe, the heat and pressure from your foot cause this cork to compress and mold to your specific foot shape, creating a custom-like fit over time.

Understanding the Modern Context

While the Goodyear welt was once a mass-market standard, its position has changed in the modern footwear landscape. Understanding this shift is key to appreciating its value today.

The Rise of Cheaper Alternatives

In the latter half of the 20th century, an even faster and cheaper method known as cement construction became dominant. In this process, the shoe's sole is simply glued to the upper. While this drastically reduces manufacturing costs, it almost entirely sacrifices durability and repairability.

Why It's a Premium Feature Today

The industry's shift toward cemented shoes has repositioned Goodyear welting as a hallmark of quality. In an era of disposable fashion, a Goodyear welt signifies a commitment to longevity, craftsmanship, and sustainable value. It is more accessible than a true hand-welted shoe but stands as a premium choice against glued footwear.

Making the Right Choice for Your Goal

Deciding if a Goodyear welt is for you depends entirely on what you value in footwear.

- If your primary focus is long-term value and sustainability: The ability to resole a Goodyear welted shoe makes it an excellent investment that can last for decades.

- If your primary focus is maximum durability and water resistance: The layered construction of a Goodyear welt offers a clear structural advantage for demanding use.

- If your primary focus is a personalized fit over time: The cork footbed provides a level of custom comfort that is difficult to achieve with other methods.

Choosing a Goodyear welted shoe is an investment in a product designed to be maintained, not replaced.

Summary Table:

| Key Factor | Impact on Accessibility |

|---|---|

| Goodyear Welting Machine | Automated the hand-sewn process, enabling mass production. |

| Increased Production Speed | Drastically reduced manufacturing time and cost. |

| Lowered Consumer Price | Made durable, repairable footwear affordable for a broad market. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including high-quality Goodyear welted footwear built for durability and long-term value. Let us help you provide your customers with superior, sustainable footwear. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the key features of winter cycling shoes designed to keep feet warm? Essential Gear for Cold Weather Rides

- What are the technical advantages of using electrodynamic shakers? Precision Tools for Biomechanical Vibration Analysis

- What is the primary function of Peltier elements in a foot thermal feedback system? High-Speed Tactile Navigation

- Why is precise temperature control in a drying oven critical for a-MWCNTs/LDHs/leather? Optimize Sensor Fabrication

- How does a high-sensitivity GPS module contribute to smart footwear safety? Enhance Monitoring with Precision Tracking

- What role do industrial-grade single-axis hydraulic actuators play? Enhancing Human-Machine Vibration Experiment Precision

- How does the randomization of environmental variables in 3D development engines improve the testing of footwear?

- Why is a high-pressure autoclave the preferred equipment for preparing E-TPU foamed granules? Expert Engineering Insights