Altering your boot lacing is a strategic technique to manage pressure and space during the critical break-in period. By selectively skipping eyelets, you can relieve painful hot spots over your arch or around the ankle, allowing the boot's leather to stretch and conform to your foot's unique shape rather than being held rigid by the laces.

The goal of breaking in boots isn't simply to endure discomfort; it's to guide the material to permanently mold to your foot. Strategic lacing creates targeted space and redirects pressure, significantly accelerating how the leather conforms to your anatomy.

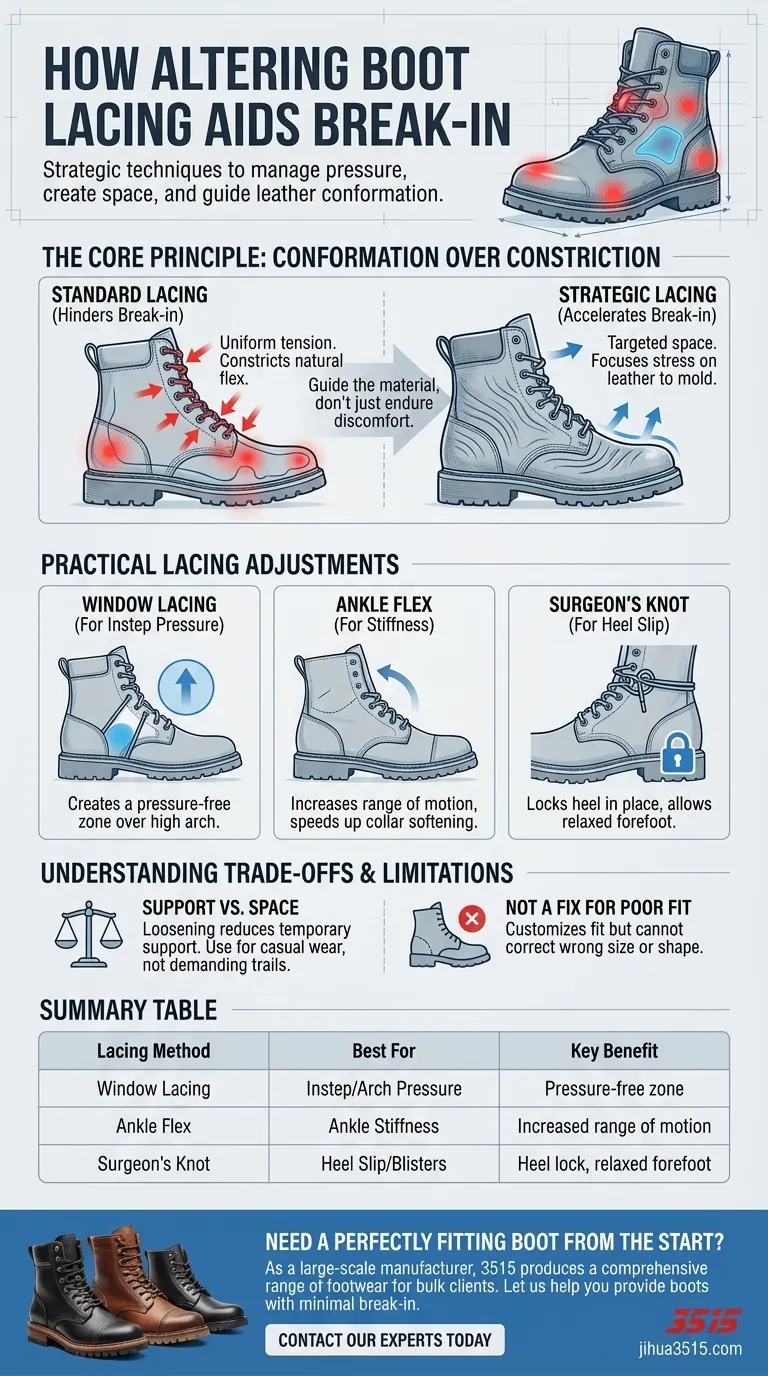

The Core Principle: Conformation Over Constriction

The break-in process is a dialogue between your foot and the boot. Stiff, new leather needs to bend, crease, and stretch in specific places. Standard factory lacing often works against this process.

Why Standard Lacing Can Hinder Break-in

Out of the box, boots are laced for presentation, creating uniform tension across the entire foot. This constriction can prevent the natural flexing and movement required for the leather to soften and stretch where you need it most.

Focusing Stress on the Leather

When laces are tight, they absorb a significant amount of the force generated by walking. By strategically loosening or skipping eyelets, you transfer that stretching force directly from the lace to the leather panels that need to give. This focuses the break-in effort on the material itself.

Creating Targeted Space

A new boot is often tightest across the instep or around the ankle. Altering the lacing in these specific zones gives your foot the physical space it needs to settle into the boot, preventing the pinching and abrasion that cause blisters.

Practical Lacing Adjustments for Break-In

Use these techniques to address common fit issues in new boots.

The "Window Lacing" Method for Instep Pressure

If you feel intense pressure on the top of your foot, skip the eyelets directly over that area. Run the laces vertically up the sides instead of crossing them over the instep. This creates a "window" that completely eliminates pressure on a high arch, a common pain point.

The "Ankle Flex" Method for Stiffness

For boots that feel excessively rigid at the ankle, try lacing them only to the eyelet just below the ankle joint. This gives the stiff leather collar a greater range of motion as you walk, speeding up the formation of natural crease lines and softening the material.

Using a Surgeon's Knot for Heel Lock

Heel slip is a primary cause of blisters. To solve this while keeping the forefoot relaxed, use a surgeon's knot (looping the lace through twice) at the eyelets just before the ankle. This locks your heel into the back of the boot, allowing you to loosen the lacing over the top of your foot without sacrificing stability.

Understanding the Trade-offs

Adjusting laces is a powerful tool, but it's important to recognize its limitations.

Support vs. Space

The primary trade-off is support. Loosening laces to create space for break-in temporarily reduces the boot's ankle and arch support. This is perfectly acceptable for casual wear around the house or office, but avoid using these techniques for the first time on a demanding trail.

A Tool for Fine-Tuning, Not a Fix for Poor Fit

Lacing techniques can customize the fit of a properly sized boot. They cannot fix a boot that is fundamentally the wrong size or shape for your foot. If your toes are crammed or the boot is too narrow, no amount of lacing adjustment will solve the core problem.

Making the Right Choice for Your Goal

Listen to what your feet are telling you and adjust your lacing accordingly.

- If your primary focus is relieving pressure on the top of your foot: Use the "window lacing" method to create a pressure-free zone over your instep.

- If your primary focus is reducing stiffness at the ankle: Lace the boots lower than normal, leaving the top one or two sets of eyelets or hooks empty.

- If your primary focus is preventing heel blisters: Employ a surgeon's knot to secure your heel while allowing the rest of your foot the space it needs.

Ultimately, treating your laces as an adjustable interface is the key to transforming a stiff new boot into a personalized piece of gear.

Summary Table:

| Lacing Method | Best For | Key Benefit |

|---|---|---|

| Window Lacing | Relieving instep/arch pressure | Creates a pressure-free zone over the top of the foot |

| Ankle Flex | Reducing ankle stiffness | Increases range of motion to soften the leather collar |

| Surgeon's Knot | Preventing heel slip/blisters | Locks the heel in place while allowing a relaxed forefoot |

Need a perfectly fitting boot from the start?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring superior comfort and fit. Let us help you provide your customers with boots that require minimal break-in.

Contact our experts today to discuss your footwear needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What dual roles does EVA foam perform in a capacitive pressure sensor? Unlocking Precision in Smart Footwear Sensors

- What role does SEM play in footwear brand reliability? Quantifying Trust and Quality with Structural Equation Modeling

- What outfit can help men stand out and draw attention? The Power of a Blazer

- What is the second method for choosing shoelace length? A Simple Guide Using Eyelet Count

- How does the mechanical unraveling process affect the quality of recycled fibers used in footwear? | Fiber Optimization

- Why is structural stability in footwear required during dual-task walking tests? Ensure Sensor Precision & Data Integrity

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why is the use of rubber or nitrile gloves essential during the pesticide mixing and loading phase? Protect Your Health