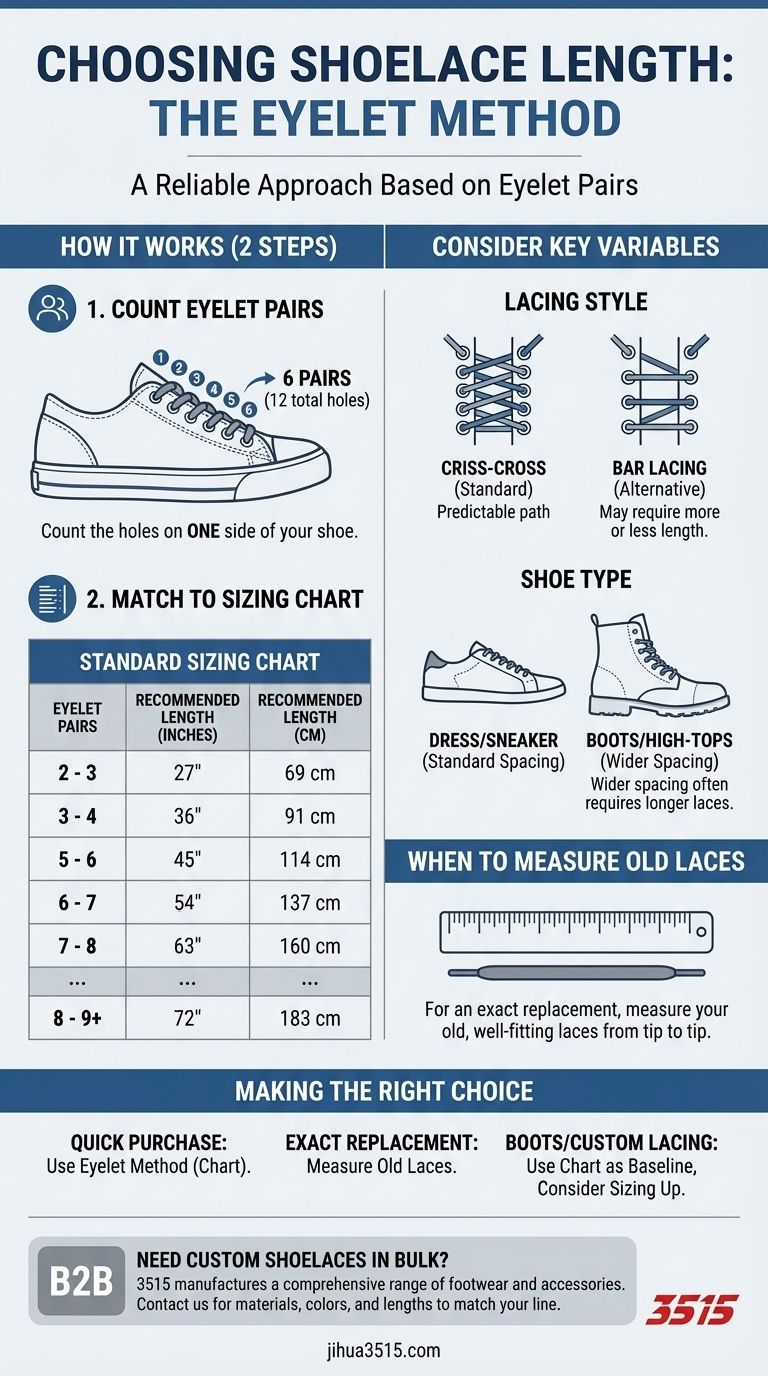

The second method for choosing shoelace length is based on the number of eyelet pairs your shoe has. To apply it, you simply count the number of lace holes on one side of your shoe and match that number to a standard sizing chart to find the recommended length. This is an excellent and reliable method when your original laces are broken, lost, or were the wrong size to begin with.

The core principle is simple: the number of eyelets provides a standardized way to estimate the required lace length. While highly effective for most situations, you must also consider factors like shoe type and lacing style for a perfect fit.

How to Apply the Eyelet Method

Applying this method is a straightforward, two-step process that removes the guesswork from buying new laces. It's the most common and practical approach used by retailers and footwear experts.

Step 1: Count the Eyelet Pairs

Look at one side of your shoe and count the number of holes (eyelets) for the lace. This number represents the "eyelet pairs." For example, a shoe with 12 total holes has 6 eyelet pairs.

Step 2: Match to a Sizing Chart

Once you have the number of eyelet pairs, use a standard conversion chart to find the corresponding lace length. This provides a highly accurate starting point for the vast majority of footwear.

| Eyelet Pairs | Recommended Length (Inches) | Recommended Length (cm) |

|---|---|---|

| 2 - 3 | 27" | 69 cm |

| 3 - 4 | 36" | 91 cm |

| 5 - 6 | 45" | 114 cm |

| 6 - 7 | 54" | 137 cm |

| 7 - 8 | 63" | 160 cm |

| 8 - 9+ | 72" | 183 cm |

Why This Method Works

The number and spacing of eyelets directly correlate to the path a shoelace must travel. More eyelets mean a longer and wider journey across the shoe's upper, requiring a longer lace. This method effectively standardizes that measurement.

Understanding the Key Variables

While the eyelet method is a powerful guide, it's based on averages for a standard shoe and a traditional criss-cross lacing pattern. Being aware of the variables ensures you make the perfect choice.

The Impact of Lacing Style

The way you lace your shoes significantly impacts the required length. A standard criss-cross pattern uses a predictable amount of lace. However, decorative or alternative styles like "bar lacing" may require more or less length to complete.

The Influence of Shoe Type

The eyelet method assumes standard spacing. Boots or high-tops, for instance, often have wider spacing between eyelets than a dress shoe or athletic sneaker. A boot with 6 eyelets may require a longer lace than a sneaker with 6 eyelets.

When to Use Another Method

The most accurate method is always to measure your existing laces, provided they were a good length. Simply remove the old lace and measure it from tip to tip. This guarantees a perfect replacement for an identical shoe and lacing style.

Making the Right Choice for Your Goal

Use your specific situation to determine the best approach.

- If your primary focus is a quick and reliable purchase: The eyelet counting method is the best all-around choice, especially when you don't have the original laces.

- If your primary focus is an exact replacement: Measure your old laces from tip to tip, assuming they fit well before.

- If you wear boots or use a custom lacing pattern: Use the eyelet chart as a baseline, but consider choosing the next size up to ensure you have enough length.

By understanding these simple principles, you can select the correct shoelace length with confidence every time.

Summary Table:

| Eyelet Pairs | Recommended Length (Inches) | Recommended Length (cm) |

|---|---|---|

| 2 - 3 | 27" | 69 cm |

| 3 - 4 | 36" | 91 cm |

| 5 - 6 | 45" | 114 cm |

| 6 - 7 | 54" | 137 cm |

| 7 - 8 | 63" | 160 cm |

| 8 - 9+ | 72" | 183 cm |

Need custom shoelaces in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and accessories for distributors, brand owners, and bulk clients. We can manufacture shoelaces in any material, color, and length to perfectly match your product line. Let us handle your production needs with precision and scale. Contact our team today for a quote!

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

People Also Ask

- How does a standardized step platform analyze lower limb fatigue? Enhance Rescue Footwear Performance Testing

- What is the function of Medium-density Ethylene-Vinyl Acetate (Md-EVA) in intelligent insoles? Enhancing Comfort & Accuracy

- What is the 60-Day Comfort Guarantee? Get a Risk-Free Boot Purchase

- How does a high-precision 3D motion capture system contribute to the evaluation of gait kinematic indicators?

- How did Goodyear Welt Construction evolve historically? From Handcrafted Luxury to Industrial Standard

- What are some hazards that can cause slips and falls in the workplace? Prevent Costly Injuries & Boost Safety

- How can one maintain the waterproofing of leather boots? A 3-Step Guide to Lasting Protection

- How does an industrial-grade hot press molding machine contribute to the production of leather composite sheets?