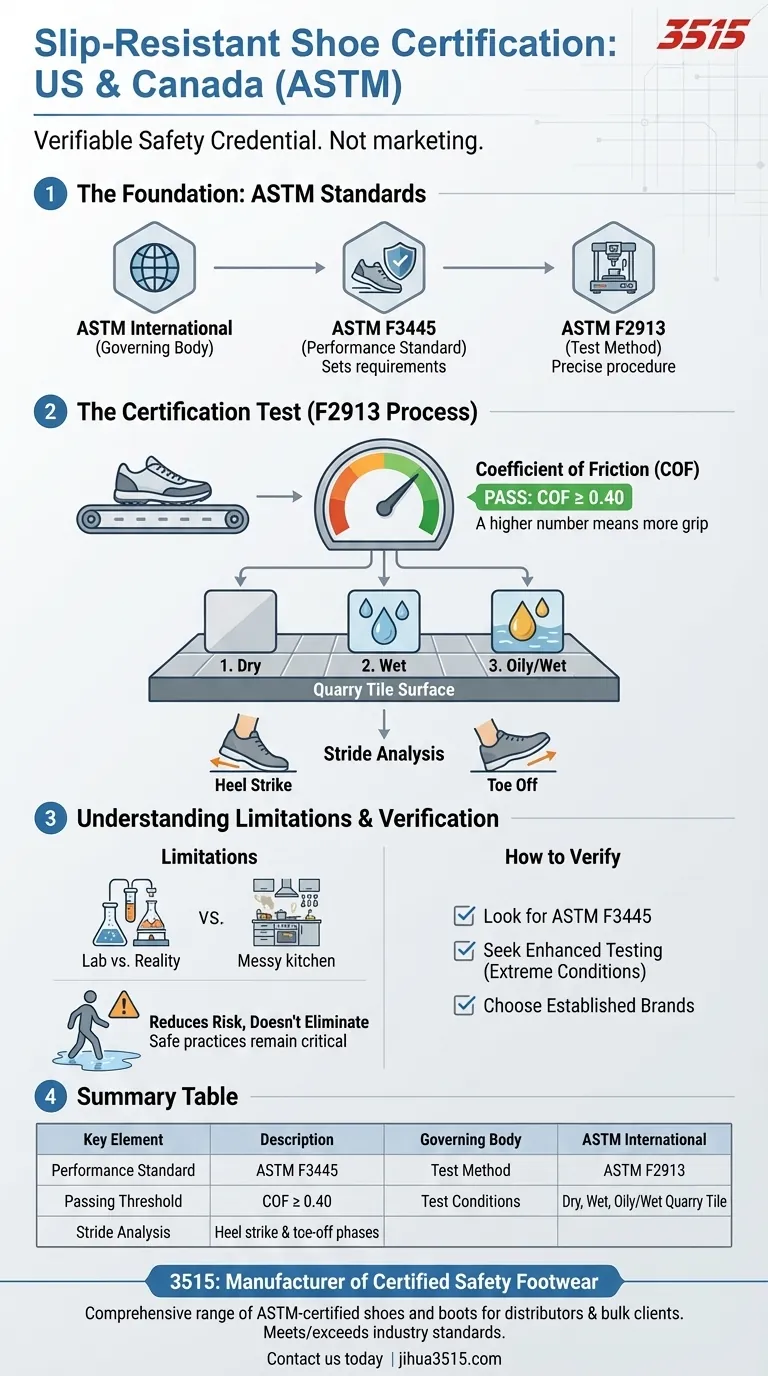

In the United States and Canada, slip-resistant shoes are certified through a standardized, scientific testing process defined by ASTM International. The core of this process is the ASTM F2913 test method, which measures a shoe's grip—its coefficient of friction (COF)—on controlled slippery surfaces. To pass, a shoe must achieve a COF of 0.40 or higher.

The "slip-resistant" label is not a marketing term but a verifiable safety credential. It signifies that a shoe has passed a rigorous laboratory test (ASTM F2913) designed to measure its ability to maintain traction on standardized wet and oily surfaces.

The Foundation of Certification: ASTM Standards

To understand slip resistance, you must first understand the role of ASTM International (formerly the American Society for Testing and Materials). This organization develops and publishes technical standards for a vast range of products and services.

The Performance Standard: ASTM F3445

The primary standard for slip-resistant footwear is ASTM F3445. This is the specification that a shoe must meet to be officially labeled as slip-resistant. It sets the performance requirements for safety footwear.

The Testing Method: ASTM F2913

Within the ASTM F3445 standard, it specifies that shoes must be tested using the ASTM F2913 method. This document details the precise, repeatable procedure for measuring the coefficient of friction.

A Look Inside the Certification Test

The certification process is designed to simulate the conditions that cause slips and falls in a professional environment. It is a highly controlled mechanical test, not a subjective human opinion.

Measuring Grip: The Coefficient of Friction (COF)

The entire test revolves around measuring the coefficient of friction (COF). In simple terms, this is a numerical value that represents the amount of grip between the shoe's outsole and the floor surface. A higher number means more grip.

The Passing Score: A 0.40 COF Threshold

To earn a passing certification under the ASTM F2913 test, a shoe must demonstrate a COF of 0.40 or greater. This number is the established benchmark for effective slip resistance in common workplace conditions.

Simulating Real-World Slips

The test is conducted on a specific surface: quarry tile. This tile is tested under three distinct conditions to replicate different workplace hazards:

- Dry

- Wet

- Oily/Wet

This ensures the shoe performs not just on a simple wet floor, but also when greasy or oily contaminants are present.

Analyzing the Full Stride

The test machine analyzes traction at two critical phases of a person's stride: the heel strike and the toe off. This provides a comprehensive picture of how the shoe will perform throughout the entire walking motion.

Understanding the Limitations

While ASTM certification is the gold standard, it's crucial to understand its context and what it doesn't cover. This awareness is key to making the safest possible choice.

Lab vs. Reality

The test uses a standardized oily/wet solution. Some work environments, like commercial kitchens or automotive shops, may have more extreme contaminants like animal fats or thick grease. A shoe that passes the standard test may perform differently in these unique conditions.

Beyond the Minimum Standard

Because the ASTM standard is a baseline, some premium footwear brands conduct their own additional testing. They may use more challenging contaminants or a wider variety of floor surfaces to ensure their products exceed the minimum requirements.

Certification Reduces Risk, It Doesn't Eliminate It

A certified slip-resistant shoe dramatically reduces the risk of a slip-and-fall accident. However, no shoe can provide a 100% guarantee. Safe work practices, clean floors, and employee awareness remain critical components of any safety program.

How to Verify a Shoe's Certification

When selecting footwear, use your knowledge of these standards to make an informed decision that prioritizes safety over marketing.

- If your primary focus is baseline safety: Look for an explicit statement that the footwear meets or complies with the ASTM F3445 standard.

- If your primary focus is performance in extreme conditions: Seek out brands that publicize their own enhanced testing on contaminants beyond the standard oily/wet tile, such as grease.

- If your primary focus is trust and verification: Choose shoes from established safety brands that clearly display their ASTM certification information and are tested by independent organizations.

Understanding these standards empowers you to look past marketing claims and choose footwear based on proven, scientific safety data.

Summary Table:

| Key Element | Description |

|---|---|

| Governing Body | ASTM International |

| Performance Standard | ASTM F3445 |

| Test Method | ASTM F2913 |

| Passing Threshold | Coefficient of Friction (COF) ≥ 0.40 |

| Test Conditions | Dry, Wet, and Oily/Wet quarry tile surfaces |

| Stride Analysis | Heel strike and toe-off phases |

Ensure your workforce is protected with certified safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, rigorously tested to meet and exceed industry standards for maximum traction and durability.

Contact us today to discuss your specific needs and discover how our certified footwear solutions can enhance workplace safety and reduce slip-and-fall risks for your customers.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- How does the floor type affect slip-resistant shoe choice? Match Your Sole to Your Surface

- What makes certain slip-resistant shoe outsoles particularly effective? The Science of Grip Explained

- What standards are used to test slip resistance in footwear? ASTM F2913 & SR Markings Explained

- How are non-slip shoes versatile? Adapt to Any Environment with One Pair of Shoes

- What are the benefits of slip-resistant work boots? Prevent Falls and Boost Workplace Safety

- Why is the weight of the shoe a key factor for worker comfort? Maximize Efficiency with Lightweight Professional Gear

- Why are non-slip shoes considered durable and long-lasting? Discover the Rugged Design Behind Their Longevity

- What advantages does ergonomic footwear provide? Maximize Protection and Comfort for High-Standing Occupations