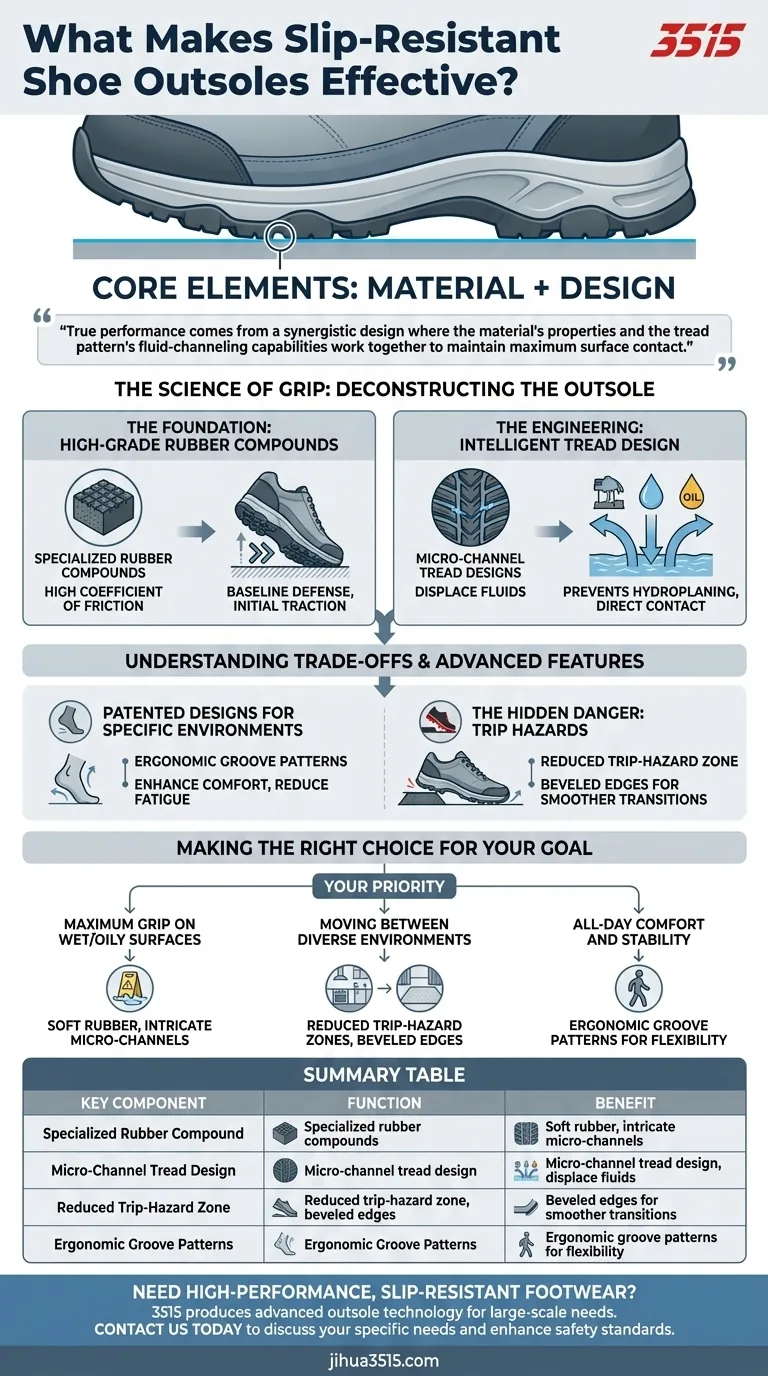

At its core, an effective slip-resistant shoe outsole combines two critical elements: a specialized rubber compound and an intelligent tread design. The material provides the fundamental friction, while the tread pattern actively clears away liquids like water and oil to ensure the rubber makes direct contact with the walking surface.

The effectiveness of a slip-resistant outsole isn't just about using "grippy" rubber. True performance comes from a synergistic design where the material's properties and the tread pattern's fluid-channeling capabilities work together to maintain maximum surface contact.

The Science of Grip: Deconstructing the Outsole

To understand what separates a genuinely effective outsole from a standard one, we need to look at its core components: the material it's made from and the design of its surface.

The Foundation: High-Grade Rubber Compounds

The first and most fundamental element is the material itself.

Not all rubber is created equal. High-performance outsoles use specialized rubber compounds specifically engineered to have a high coefficient of friction, which is the scientific measure of "grip."

This specialized material is the baseline defense against slickness, providing the initial traction needed to prevent a slip before the tread pattern even comes into play.

The Engineering: Intelligent Tread Design

While the material provides potential grip, the tread design makes that grip functional on contaminated surfaces.

The primary job of the tread is to displace fluids. When you step on a wet or oily floor, a layer of liquid can get trapped between your shoe and the ground, causing hydroplaning and a subsequent fall.

Effective outsoles feature micro-channel tread designs. These intricate groove patterns act like the treads on a car tire, quickly funneling water and oil away from the center of the outsole. This clears a path for the rubber to make solid, direct contact with the floor, maximizing friction.

Understanding the Trade-offs and Advanced Features

Beyond the core components, top-tier designs incorporate features that address real-world workplace dynamics, but these often come with design trade-offs.

Patented Designs for Specific Environments

Many leading brands have patented outsole designs tailored for specific challenges. This includes groove patterns that mimic the foot's natural flexing motion to enhance comfort and reduce fatigue during long shifts.

These ergonomic designs help maintain proper footing and stability, not just by preventing slips, but by supporting the wearer's natural movement.

The Hidden Danger: Trip Hazards

An often-overlooked feature is the reduced trip-hazard zone. Aggressive, deep lugs are excellent for grip but can catch on uneven surfaces, flooring transitions, or mats, creating a trip hazard.

More advanced designs feature beveled or smoother edges, allowing for a more fluid transition between different environments without sacrificing the core slip-resistant functionality. This is a critical consideration in dynamic workplaces.

Making the Right Choice for Your Goal

Choosing the right shoe depends entirely on your specific work environment and priorities.

- If your primary focus is maximum grip on wet or oily flat surfaces: Prioritize shoes with soft rubber compounds and intricate, dense micro-channel tread patterns for superior fluid displacement.

- If your primary focus is moving between diverse environments (e.g., from a kitchen to a carpeted area): Look for designs that explicitly mention reduced trip-hazard zones or beveled edges for safer transitions.

- If your primary focus is all-day comfort and stability: Seek out outsoles with patented, ergonomic groove patterns designed to flex with the natural motion of your foot.

Ultimately, the most effective outsole is the one that intelligently combines material science and engineering to solve the specific challenges of your environment.

Summary Table:

| Key Component | Function | Benefit |

|---|---|---|

| Specialized Rubber Compound | Provides high coefficient of friction | Creates fundamental grip and traction |

| Micro-Channel Tread Design | Actively displaces water, oil, and liquids | Prevents hydroplaning, ensures surface contact |

| Reduced Trip-Hazard Zone | Features beveled or smoother edges | Minimizes catching on uneven surfaces, enhances safety |

| Ergonomic Groove Patterns | Flexes with the natural motion of the foot | Improves comfort, stability, and reduces fatigue |

Need high-performance, slip-resistant footwear for your workforce? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with advanced outsole technology for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of occupational shoes and boots, engineered with the precise rubber compounds and tread patterns detailed above to maximize safety and comfort in any environment. Contact us today to discuss your specific needs and discover how we can enhance your safety standards.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Is safety toe better than steel toe? A Guide to Choosing the Right Protection

- What is a working boot? Your Essential Guide to Foot Safety and Durability

- How do safety shoes protect you? A Guide to Essential Footwear Safety Features

- What should I look for in a safety shoe? Find the Perfect Protection for Your Job

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes