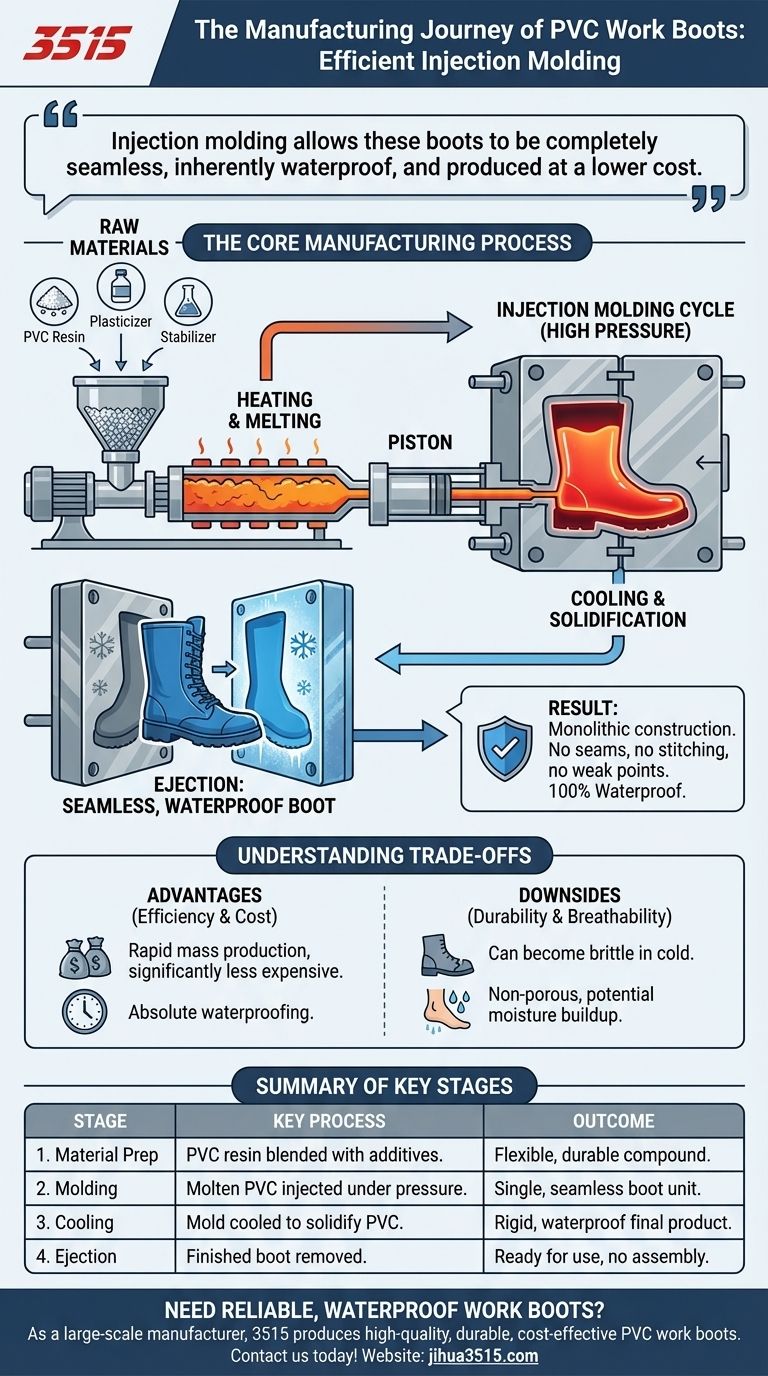

PVC work boots are manufactured through a highly efficient process called injection molding. This method involves heating a specialized compound of polyvinyl chloride (PVC) until it becomes molten and then injecting it under high pressure into a boot-shaped mold. The mold is then cooled, allowing the PVC to solidify into a single, seamless, and waterproof final product.

The use of injection molding is the defining characteristic of PVC boot manufacturing. This single-step process is what allows these boots to be completely seamless, inherently waterproof, and produced at a lower cost than traditionally constructed footwear.

The Core Manufacturing Process: From Pellets to Boot

Understanding the journey from raw plastic pellets to a finished boot reveals why PVC is a popular choice for protective footwear. The entire process is built around speed, consistency, and creating an impenetrable barrier.

The Material Foundation: Polyvinyl Chloride (PVC)

At its core, the boot is made from polyvinyl chloride, a synthetic plastic polymer. This raw material is chosen for its innate resistance to water, chemicals, and abrasion, forming the base of the boot's protective qualities.

The Critical Additives

Raw PVC is rarely used alone. It is blended with several key additives to achieve the desired characteristics for a work boot.

- PVC Resin: This is the primary polymer that determines the boot's fundamental durability and chemical resistance.

- Plasticizer: This crucial additive increases the softness and flexibility of the final product, ensuring the boot is comfortable to wear and walk in.

- Stabilizer: During the heating and molding process, stabilizers are essential to prevent the PVC from decomposing or burning, ensuring a consistent and structurally sound boot.

- Other Additives: Depending on the boot's intended use, manufacturers may also include colorants, flame retardants, antioxidants, or fillers to enhance specific properties.

The Injection Molding Cycle

The actual creation of the boot is a rapid, automated cycle. The prepared PVC compound is fed into a machine, heated to a precise molten temperature, and then forcefully injected into a two-part steel mold shaped like a boot. The mold is then rapidly cooled, causing the PVC to harden into its final form before the mold opens and ejects the finished boot.

The Result: A Seamless, Waterproof Barrier

Because the entire boot is formed in a single action, it has no seams, stitching, or glued joints. This monolithic construction is the reason PVC boots offer exceptional waterproof protection, as there are no weak points for water or other liquids to penetrate.

Understanding the Trade-offs of PVC Construction

While the manufacturing process creates a highly effective and affordable boot, it's important to understand the inherent trade-offs that come with the material and method.

Key Advantages: Waterproofing and Cost

The primary advantage of PVC injection molding is its efficiency. This process allows for the rapid mass production of footwear, making PVC boots significantly less expensive than their rubber or leather counterparts. Their seamless design provides a level of waterproofing that is nearly absolute.

Potential Downsides: Durability and Breathability

While durable, PVC can become stiff and brittle in very cold temperatures and may not offer the same long-term abrasion resistance as high-grade vulcanized rubber. Furthermore, as a non-porous plastic, PVC does not breathe, which can lead to moisture buildup inside the boot during prolonged wear in warm conditions.

Making the Right Choice for Your Needs

Selecting the correct boot depends entirely on the demands of your environment.

- If your primary focus is complete waterproofing for wet or muddy conditions on a budget: A PVC work boot is an excellent and highly practical choice.

- If your primary focus is working in extremely cold temperatures or needing high flexibility: You may want to consider rubber boots, which often retain their flexibility better in the cold.

- If your primary focus is all-day wear in a variety of temperatures: A boot made from a breathable material like leather with a waterproof membrane may provide more long-term comfort.

Ultimately, the manufacturing process of PVC boots makes them a specialized tool for providing affordable and reliable waterproof protection.

Summary Table:

| Stage | Key Process | Outcome |

|---|---|---|

| 1. Material Prep | PVC resin is blended with plasticizers and stabilizers. | Creates a flexible, durable compound. |

| 2. Molding | Molten PVC is injected under high pressure into a boot-shaped mold. | Forms a single, seamless boot unit. |

| 3. Cooling | The mold is cooled to solidify the PVC. | Results in a rigid, waterproof final product. |

| 4. Ejection | The finished boot is removed from the mold. | Boot is ready for use, with no assembly required. |

Need reliable, waterproof work boots for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our advanced injection molding capabilities ensure high-quality, durable, and cost-effective PVC work boots tailored to your specifications.

Contact us today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Can insulated boots cause feet to sweat? How to ensure dry warmth with the right materials.

- Why check ASTM F2413 version when selecting safety boots? Ensure maximum protection and compliance.

- Why are safety boots designated as a core detection target in PPE monitoring? Enhance Industrial Safety Compliance

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort

- How should lace-up boots be properly worn? Master the Fit for All-Day Comfort and Support

- How does the Goodyear Welt Construction process work? Discover the Secret to Decades-Lasting Footwear

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What are the differences between women's and men's work boots? Key Anatomical Design Factors for Safety & Comfort