At its core, Goodyear Welt Construction is a traditional shoemaking method where a strip of leather, known as the "welt," acts as a middleman between the upper part of the shoe and the sole. This welt is first stitched to the upper and the insole, and then the outsole is stitched directly to the welt. This two-level stitching process creates an exceptionally durable and easily repairable shoe.

The true genius of the Goodyear welt lies in its architecture. By stitching the sole to the welt instead of directly to the upper, it creates a robust, water-resistant, and endlessly repairable platform that allows a shoe to last for decades, not just seasons.

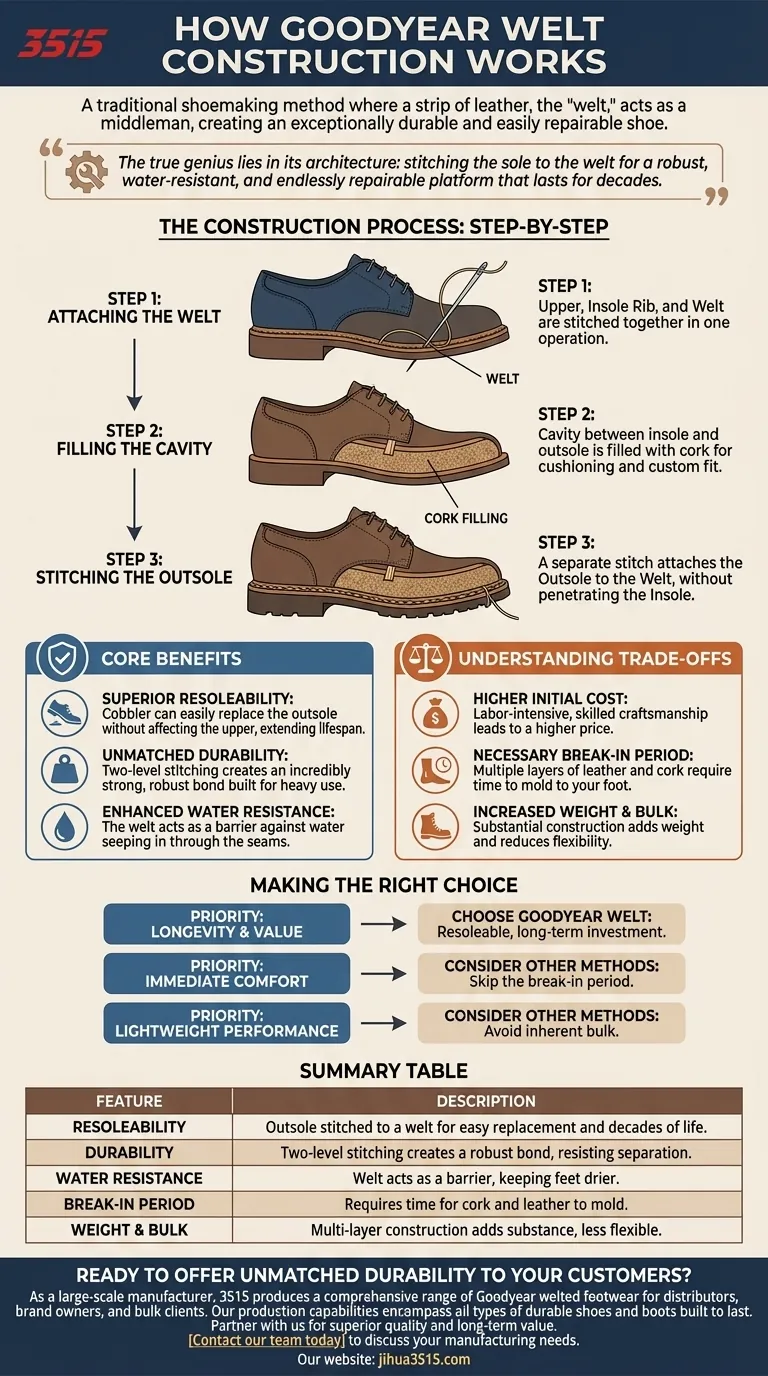

How a Goodyear Welt Is Constructed

To understand why this method is considered a gold standard, it’s helpful to visualize the key steps. It is a precise process that builds the shoe in distinct, durable layers.

The Key Components

A Goodyear welted shoe is an assembly of several critical parts. The upper is the main body of the shoe that covers your foot. The insole is the material inside directly beneath your foot. The welt is a dedicated strip of leather, and the outsole is the layer that contacts the ground.

Step 1: Attaching the Welt

The process begins by preparing the insole with a perpendicular "rib" or ridge that runs along its edge. The upper is pulled taut over the shoe last (a foot-shaped mold), and its edge is stitched securely to this insole rib. In the same stitch, the leather welt is attached, locking all three components—upper, insole, and welt—together.

Step 2: Filling the Cavity

This stitching method creates a natural cavity between the insole and the outsole. This space is filled with a layer of granulated cork. This cork filling provides cushioning, insulation, and, over time, molds to the shape of your foot for a custom fit.

Step 3: Stitching the Outsole

Finally, the outsole is attached. A separate, heavy-duty stitch is used to sew the outsole directly to the welt, running around the outside of the shoe. This is the visible stitch you often see on the top edge of a welted shoe's sole. Because this stitch never penetrates the insole, the integrity of the upper is never compromised.

The Core Benefits of This Method

The complexity of the Goodyear welt process directly translates into tangible, long-term advantages for the owner.

Superior Resoleability

This is the most significant benefit. Since the outsole is only stitched to the welt, a cobbler can easily remove the old sole and stitch on a new one without disturbing the fundamental structure of the shoe. This allows for multiple resoles, dramatically extending the footwear's lifespan.

Unmatched Durability

The two-level stitching system creates an incredibly strong bond between all parts of the shoe. This robust construction is built to withstand heavy use and years of wear, resisting the sole separation common in cheaper, cemented footwear.

Enhanced Water Resistance

The welt acts as a small wall or buffer between the upper and the outsole. This design makes it much more difficult for water on the ground to seep into the shoe through the seams, keeping your feet drier than other construction methods.

Understanding the Trade-offs

While revered, the Goodyear welt is not the perfect solution for every situation. Its robust nature comes with inherent compromises.

The Higher Initial Cost

Goodyear welting is a labor-intensive and material-heavy process that requires skilled craftsmanship. This intricacy and quality naturally result in a higher purchase price compared to simpler construction methods.

A Necessary Break-in Period

The multiple layers of thick leather, the cork footbed, and the sturdy stitching make new Goodyear welted shoes notoriously stiff. They require a significant break-in period as the cork molds to your foot and the leather becomes more pliable.

Increased Weight and Bulk

This construction method is, by definition, substantial. The extra layers of the welt and midsole add weight and create a less flexible shoe, which may not be ideal for activities requiring agility or lightweight footwear.

Making the Right Choice for Your Goal

Deciding if Goodyear welted footwear is right for you depends entirely on your priorities.

- If your primary focus is longevity and value over time: A Goodyear welt is the undisputed champion, as its resoleable nature makes it a long-term investment.

- If your primary focus is immediate, out-of-the-box comfort: You may prefer a more flexible construction that forgoes the stiff break-in period.

- If your primary focus is lightweight performance: The inherent bulk of a Goodyear welt makes it less suitable than modern, bonded constructions for athletic or highly mobile use.

Ultimately, choosing a Goodyear welt is an investment in a durable, repairable footwear platform that trades initial flexibility for a potential lifetime of service.

Summary Table:

| Key Feature | Description |

|---|---|

| Resoleability | Outsole is stitched to a welt, allowing for easy replacement and extending the shoe's life for decades. |

| Durability | Two-level stitching creates a robust bond, resisting sole separation and heavy wear. |

| Water Resistance | The welt acts as a barrier, making it difficult for water to seep into the shoe. |

| Break-in Period | Requires time for the cork footbed to mold to your foot and the leather to soften. |

| Weight & Bulk | The multi-layer construction adds substance, resulting in a less flexible, heavier shoe. |

Ready to Offer Unmatched Durability to Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots built to last.

Partner with us to provide your customers with the superior quality and long-term value of Goodyear welt construction. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear