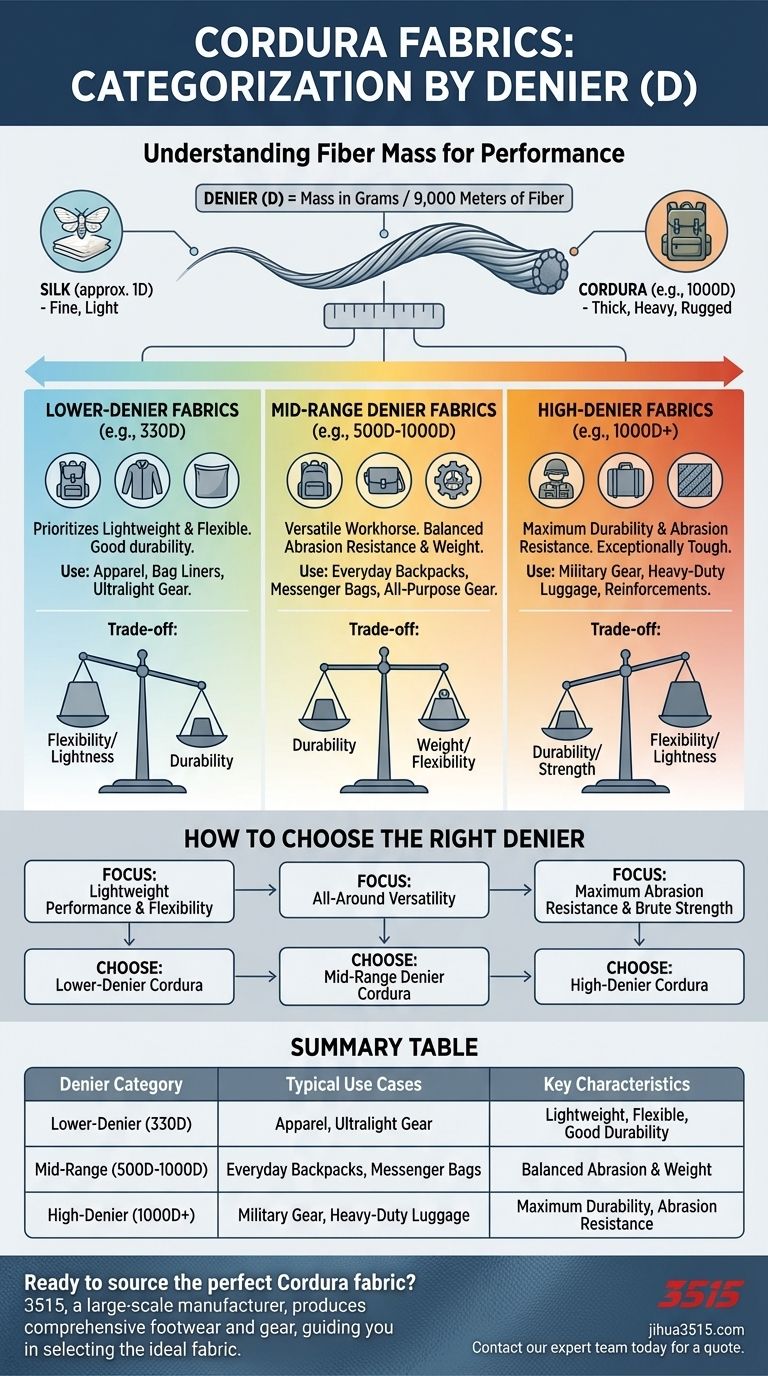

At its core, Cordura fabric is categorized by its denier (D), which is a direct measurement of the linear mass density of its fibers. Put simply, denier tells you the thickness and weight of the individual threads woven together to create the material. A higher denier number signifies a thicker, heavier, and generally more rugged fiber, while a lower denier indicates a lighter and more flexible one.

Choosing the right Cordura isn't about finding the "strongest" option. It's about understanding the trade-off between durability, weight, and flexibility, and matching the fabric's denier to your specific application.

What Exactly is Denier?

Denier is a surprisingly straightforward unit of measurement, but its implications for fabric performance are significant. Understanding it is key to selecting the right material.

A Measure of Fiber Mass

The technical definition of denier is the mass in grams per 9,000 meters of a single fiber.

This means if you had a strand of fiber 9,000 meters long that weighed 500 grams, it would be classified as a 500D fiber.

An Analogy: A Strand of Hair

Think of it like this: a single strand of silk is about 1 denier, making it incredibly fine and light. A 1000D Cordura fiber, by contrast, is vastly thicker and heavier.

A low-denier fiber is like a fine thread, while a high-denier fiber is more like a thick cord.

Decoding Cordura's Common Categories

While Cordura comes in many specific weights, its fabrics generally fall into three practical categories based on their denier.

Lower-Denier Fabrics

These fabrics prioritize being lightweight and flexible while still offering significantly more durability than standard nylon or polyester.

They are often used for apparel, bag liners, or ultralight backpacks where saving weight is a primary concern.

Mid-Range Denier Fabrics

This category represents the versatile workhorse of the Cordura family. It offers an excellent balance of substantial abrasion resistance without becoming excessively heavy or stiff.

This is the sweet spot for everyday backpacks, messenger bags, and all-purpose gear that needs to withstand regular use.

High-Denier Fabrics

These are the heavy-duty options engineered for maximum durability and abrasion resistance. The thick fibers create an exceptionally tough material.

You'll find high-denier Cordura used for military gear, heavy-duty luggage, and reinforcement panels on bags that are exposed to constant friction and abuse.

Understanding the Trade-offs

Selecting a Cordura fabric is a balancing act. A higher denier isn't always the better choice, as every increase in durability comes with a trade-off.

Durability vs. Weight

The core trade-off is simple: thicker fibers are stronger but also heavier. A 1000D Cordura pack will be exceptionally tough but noticeably heavier than an identical pack made from 500D fabric.

Abrasion Resistance vs. Flexibility

Higher-denier fabrics are not just heavier; they are also stiffer. The thick, robust weave that excels at resisting scuffs and tears is less pliable and may not be suitable for products that need to be soft or flexible.

How to Choose the Right Denier for Your Needs

Base your decision on the primary demand of your application.

- If your primary focus is lightweight performance and flexibility: Opt for lower-denier Cordura for applications like apparel or ultralight gear.

- If your primary focus is all-around versatility for everyday equipment: A mid-range denier provides the ideal balance of ruggedness and manageable weight.

- If your primary focus is maximum abrasion resistance and brute strength: Choose high-denier Cordura for gear destined for the most demanding environments.

By understanding denier, you can move beyond marketing terms and select a fabric precisely engineered for your intended use.

Summary Table:

| Denier Category | Typical Use Cases | Key Characteristics |

|---|---|---|

| Lower-Denier (e.g., 330D) | Apparel, bag liners, ultralight gear | Lightweight, flexible, good durability |

| Mid-Range (e.g., 500D-1000D) | Everyday backpacks, messenger bags | Balanced abrasion resistance and weight |

| High-Denier (e.g., 1000D+) | Military gear, heavy-duty luggage, reinforcements | Maximum durability and abrasion resistance |

Ready to source the perfect Cordura fabric for your product line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and gear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we can expertly guide you in selecting the ideal fabric—whether you need lightweight flexibility or maximum durability—to ensure your products excel in their market.

Contact our expert team today to discuss your specific fabric needs and get a quote.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Leather Derby Shoes Manufacturer | Customizable Business & Dress Footwear

- Factory Direct Wholesale Leather Comfort Shoes with Dial Closure

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

People Also Ask

- What emotional appeal do cowboy boots have? Unleash Rugged Individualism and Personal Style

- Why are motorcycle boots essential safety gear? Protect Your Feet and Ankles from Catastrophic Injury

- What is the role of surface electromyography (EMG) sensors in footwear? Quantify Muscle Load & Safety

- What are the different finishes applied to leather? A Guide to Aniline, Pigmented & More

- What are the advantages of integrating AHP and TOPSIS for footwear material supplier selection? Master Supplier Logic

- What is the role of advanced SEM software in analyzing market engagement behavior for occupational footwear?

- Why is the assessment of gait biomechanics important for footwear selection? Optimize Athletic Safety & Performance

- What makes Funchal leather exceptional? Discover the Luxury of French Full-Grain Calfskin