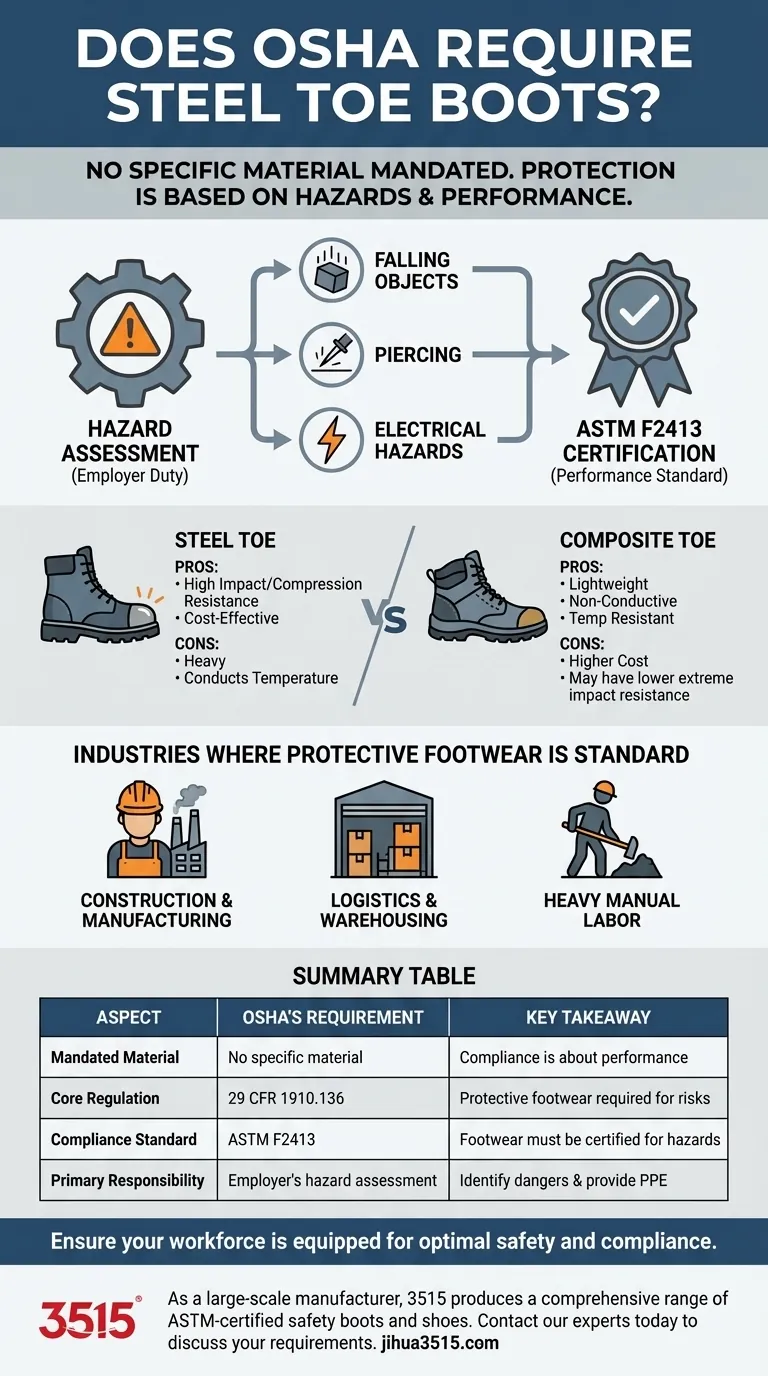

The short answer is no. The Occupational Safety and Health Administration (OSHA) does not specifically mandate that workers wear steel toe boots. Instead, OSHA requires employers to ensure their employees use protective footwear in any workplace where there is a danger of foot injury. This protection can be provided by either steel toe or composite toe boots, as long as they meet the performance standards set by ASTM International.

The core principle of OSHA's footwear regulation is not about specifying a material like steel, but about mandating a level of performance. The employer's responsibility is to assess workplace hazards and provide footwear certified to protect against those specific risks, regardless of its construction.

The Core of the OSHA Mandate: Hazard Assessment, Not Material

OSHA's rules on personal protective equipment (PPE) are designed to be performance-based. This means they focus on the effectiveness of the protection, not the specific product or material used to provide it.

Understanding the Key Regulation

The relevant standard, OSHA 29 CFR 1910.136, states that employers must ensure employees use protective footwear when they are at risk of foot injuries. These risks include falling or rolling objects, items piercing the sole, and electrical hazards.

The Employer's Duty

The responsibility begins with the employer conducting a hazard assessment of the worksite. This process identifies the specific types of foot dangers present, which in turn determines the type of protective footwear required.

It's About the Standard, Not the Steel

The key to compliance is ensuring the footwear meets the standards outlined in ASTM F2413 (Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear). A boot that meets this standard is certified to protect against specific hazards like impact and compression, whether its toe cap is made of steel, aluminum, or a composite material.

Industries Where Protective Footwear Is Standard Practice

While OSHA does not name specific industries, the hazard-based requirement means protective footwear is a practical necessity in many fields. The presence of heavy materials, moving equipment, and sharp objects makes safety-toe boots non-negotiable.

Construction and Manufacturing

These environments present constant risks from falling tools, heavy materials, and moving machinery. Protective footwear is a fundamental safety requirement to prevent crushing injuries.

Logistics and Warehousing

Workers in this sector regularly interact with forklifts, pallet jacks, and heavy packages. A certified safety toe is essential to protect against dropped freight and equipment-related accidents.

Heavy Manual Labor

Fields like farming, disaster relief, and even fishing involve significant foot hazards. These can range from stepping on sharp objects and debris to injuries from heavy equipment or tools.

Understanding the Trade-offs: Steel vs. Composite

Since OSHA allows for different materials, the choice between steel and composite toe boots comes down to the specific needs of the job and the wearer. Both are compliant if they carry the proper ASTM rating.

The Case for Steel Toe

Steel has been the industry standard for decades for a reason. It often provides superior resistance to very high-impact and compression forces and is typically a cost-effective option. However, it is heavier and conducts temperature, which can be a drawback in very hot or cold environments.

The Case for Composite Toe

Composite toe caps are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are significantly lighter, do not conduct electricity, and don't transfer cold or heat. This makes them ideal for jobs requiring more agility or for workers who must pass through metal detectors.

The Deciding Factor: The Certified Rating

Ultimately, the material is secondary to the certification. A boot's tag will specify the ASTM F2413 standard and indicate the exact hazards it is rated to protect against (e.g., I/75 for impact, C/75 for compression, EH for electrical hazard). This rating is your guarantee of compliance.

Making the Right Choice for Your Goal

Choosing the correct footwear is about matching the boot's certified protection to the specific hazards you've identified in your workplace.

- If your primary focus is OSHA compliance: Ensure any chosen boot, steel or composite, is certified to meet the current ASTM F2413 standard for the specific hazards present in your workplace.

- If your primary focus is protection from extreme impact: Steel toe boots have a long-standing reputation for providing maximum protection against crushing and falling objects.

- If your primary focus is employee comfort or work in varied temperatures: Composite toe boots are often lighter and do not conduct cold or heat, which can be a significant factor in employee adoption and overall safety.

A thorough and accurate hazard assessment is the true foundation of a compliant and safe work environment.

Summary Table:

| Aspect | OSHA's Requirement | Key Takeaway |

|---|---|---|

| Mandated Material | No specific material (steel, composite, etc.) | Compliance is about performance, not material. |

| Core Regulation | 29 CFR 1910.136 | Protective footwear required where foot injury risks exist. |

| Compliance Standard | ASTM F2413 certification | Footwear must be certified for specific hazards (impact, compression, etc.). |

| Primary Responsibility | Employer's hazard assessment | Employers must identify workplace dangers and provide appropriate PPE. |

Ensure your workforce is equipped with the right protective footwear for optimal safety and compliance.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, from durable steel toe boots to lightweight composite toe options, ensuring you find the perfect match for your hazard assessment needs.

Let us help you protect your team. Contact our experts today to discuss your requirements and request a quote.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What is the primary purpose of steel toe cap safety boots? Ultimate Toe Protection for Hazardous Work

- Why is it necessary to conduct mechanical strength evaluations on polycarbonate toecaps? Ensure Impact Safety & Comfort

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What are the advantages of alloy toe work shoes? Lighter Weight, Superior Comfort

- Which occupations typically require steel toe boots? A Guide to Essential Foot Protection

- What types of workplaces are steel toe boots traditionally used in? Essential Foot Protection for Hazardous Jobs

- What industries are steel toe boots commonly used in? Essential Foot Protection for High-Risk Work

- What materials are used for impact-resistant toes? Steel, Aluminum, or Composite?