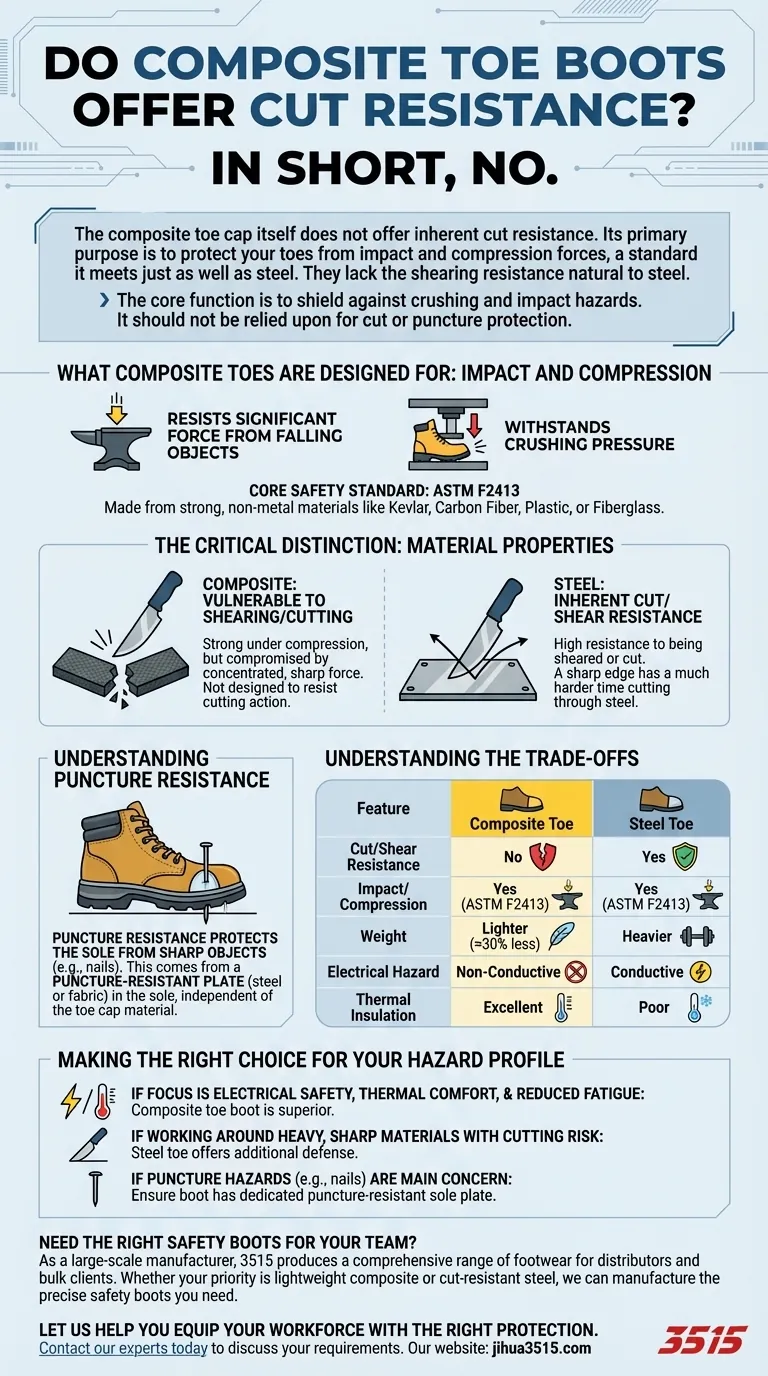

In short, no. The composite toe cap itself does not offer inherent cut resistance. Its primary purpose is to protect your toes from impact and compression forces, a standard it meets just as well as steel. However, the material properties that make composite toes light and non-conductive also mean they lack the shearing resistance that is a natural property of steel.

The core function of a composite safety toe is to shield against crushing and impact hazards. While it excels in this role, it should not be relied upon for cut or puncture protection, which are properties inherent to steel or are provided by other specialized materials in the boot's construction.

What Composite Toes Are Designed For: Impact and Compression

The Core Safety Standard

Composite toe boots are certified to meet the same ASTM F2413 safety standards for impact and compression resistance as their steel toe counterparts. This is their fundamental, non-negotiable safety feature.

These toe caps are made from strong, non-metal materials like Kevlar, carbon fiber, plastic, or fiberglass. They are engineered to withstand significant force from falling objects or crushing pressure.

The "Why" Behind the Design

The primary goal of any safety toe is to prevent your toes from being crushed. Both composite and steel achieve this. The invention of the composite toe was driven by a need to solve the secondary problems associated with steel.

The Critical Distinction: Material Properties

Composite vs. Steel for Cut Resistance

Steel, being a metal, has a high resistance to being sheared or cut. A sharp edge, like the blade of a heavy tool, will have a much harder time cutting through a steel cap than a composite one.

Composite materials, while very strong under compression, can be compromised or fractured by a concentrated, sharp force. They are not designed to resist a cutting or shearing action.

Understanding Puncture Resistance

Puncture resistance is an entirely different safety feature. This protects the bottom of your foot from sharp objects like nails.

This protection comes from a puncture-resistant plate built into the boot's sole. This plate can be made of steel or a flexible composite fabric like Kevlar. The material of the toe cap has no bearing on a boot's puncture resistance.

Look at the Whole Boot

A boot's overall cut resistance often depends more on the upper materials than the toe cap. Boots designed for high-risk environments may use cut-resistant fabrics throughout their construction, independent of whether the toe is steel or composite.

Understanding the Trade-offs

Choosing between composite and steel is about matching the boot's properties to your specific work environment and priorities. Neither is universally "better"; they are simply different tools for different jobs.

The Case for Composite Toes

Workers often choose composite toes for several key advantages. They are roughly 30% lighter than steel toes, which significantly reduces foot fatigue over a long day.

They are also non-conductive to electricity and provide excellent thermal insulation, making them ideal for electricians or those working in extreme hot or cold conditions. Finally, they do not set off metal detectors, a major convenience in secure facilities.

The Case for Steel Toes

The primary advantage of steel is its sheer durability. Beyond impact protection, it offers superior resistance to cuts and punctures.

While a composite cap might shatter under an extreme impact that exceeds its rating, a steel cap is more likely to bend. This can still trap the foot but may be preferable in certain accident scenarios.

Making the Right Choice for Your Hazard Profile

To select the correct boot, you must accurately assess the risks of your job. The toe cap is just one component of a complex piece of personal protective equipment.

- If your primary focus is electrical safety, thermal comfort, and reduced fatigue: A composite toe boot is the clear and superior choice for your needs.

- If you work around heavy, sharp materials with a tangible risk of cutting or shearing: A steel toe offers an additional layer of defense that composite materials do not provide.

- If puncture hazards like nails are your main concern: Ensure the boot you choose has a dedicated puncture-resistant sole plate, regardless of the toe cap material.

Ultimately, understanding these specific protections allows you to select the boot that truly matches the hazards of your workplace.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Impact/Compression Protection | Yes (ASTM F2413) | Yes (ASTM F2413) |

| Cut/Shear Resistance | No | Yes |

| Weight | Lighter (≈30% less) | Heavier |

| Electrical Hazard | Non-Conductive | Conductive |

| Thermal Insulation | Excellent | Poor |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We can manufacture the precise safety boots you need—whether your priority is the lightweight, non-conductive comfort of composite toes or the superior cut resistance of steel.

Let us help you equip your workforce with the right protection. Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Why is safety the top priority when selecting oilfield work boots? Essential Protection for High-Risk Environments

- What is the importance of ASTM International in safety footwear standards? Ensure OSHA Compliance and Worker Safety

- What is the ASTM standard for puncture resistance? A Guide to Selecting the Right Protective Footwear

- What is the purpose of puncture-resistant footwear? Protect Your Feet from Sharp Hazards