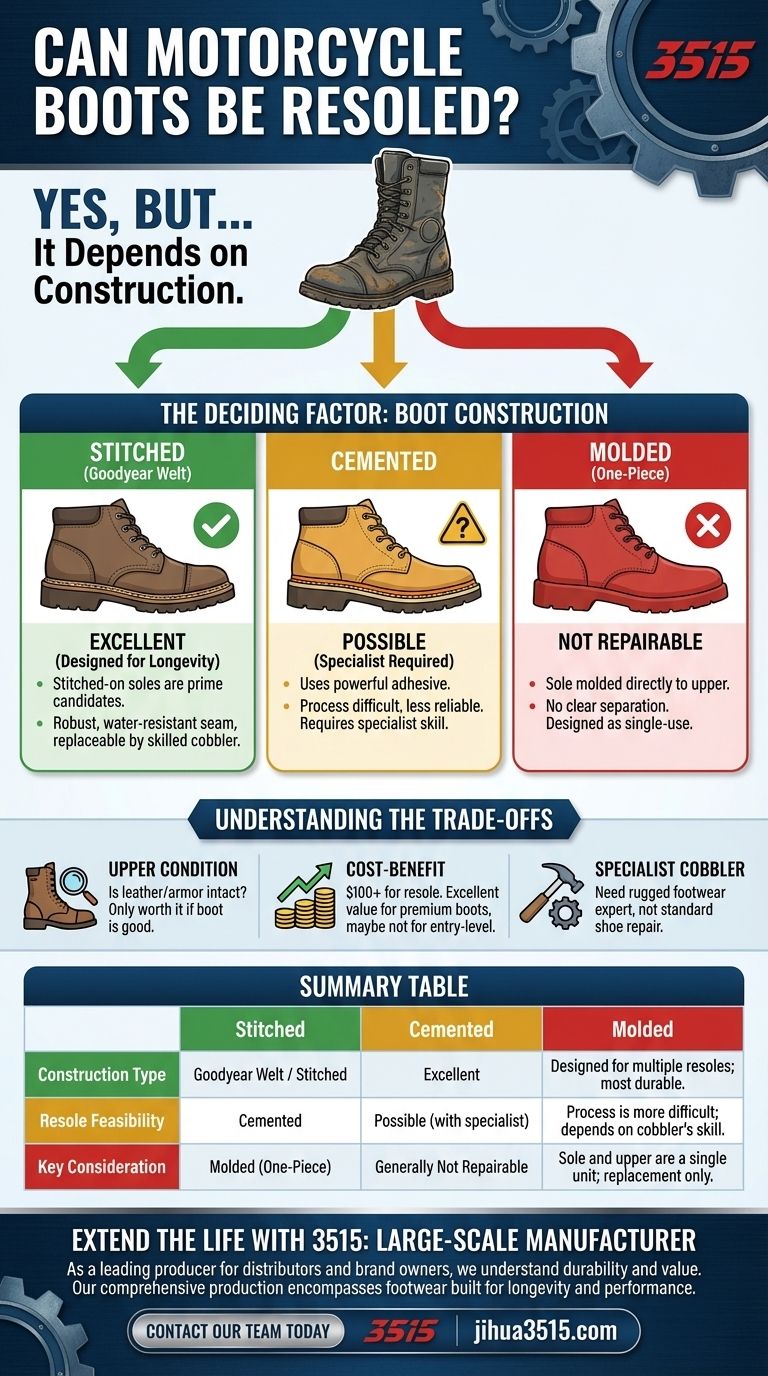

Yes, in many cases, motorcycle boots can be resoled. However, the feasibility and cost-effectiveness of this repair depend almost entirely on how the boot was originally constructed. Before you discard a pair of worn-out favorites, you must determine if the sole was designed to be replaceable.

The critical factor is not the brand or material, but the construction method used to attach the sole. Boots with stitched-on soles are prime candidates for resoling, while those with cemented or molded soles present a significant challenge that may not be worth the cost.

The Deciding Factor: Boot Construction

The ability to resole a boot is engineered into it from the start. Understanding the basic difference between construction methods will tell you almost everything you need to know.

Stitched Soles: Built for Longevity

The most durable and repair-friendly boots use a Goodyear welt or a similar stitched construction. This method involves a strip of leather (the welt) stitched to the boot's upper, and the outsole is then stitched to the welt.

This creates a robust, water-resistant seam that can be unstitched by a skilled cobbler, allowing for the old sole to be removed and a new one attached without compromising the boot's main structure.

Cemented Soles: The Modern Standard

Many modern motorcycle boots, especially those with complex designs or lower price points, use a cemented construction. The sole is attached to the upper using a powerful, high-grade adhesive.

While some cemented boots can be resoled by a specialist with the right equipment, the process is more difficult and less reliable than with a stitched boot. The quality of the repair is highly dependent on the cobbler's skill.

Molded Soles: Generally Not Repairable

Some boots, particularly in the adventure or motocross categories, feature a sole that is molded directly onto the boot upper or is part of a single, unified piece of material.

If there is no clear separation or seam between the sole and the rest of the boot, it is almost certainly impossible to resole. The boot is designed as a single-use item in this regard.

Understanding the Trade-offs

Resoling can be an excellent investment, but you must be aware of the potential downsides before proceeding. A professional assessment is non-negotiable.

The Condition of the Upper

Resoling is only worthwhile if the rest of the boot is in good condition. If the leather is cracked, zippers are broken, or the protective armor is compromised, putting a new sole on a failing boot is a poor investment.

The Cost-Benefit Analysis

A professional resoling service for rugged footwear typically costs around $100 or more. For a premium pair of boots that cost $400+, this is an excellent value that can double their lifespan.

However, for an entry-level pair of boots that cost $150, paying for a resole might not make financial sense compared to buying a new pair.

Not All Cobblers Are Equal

Do not take your high-performance motorcycle boots to a standard shoe repair shop that primarily deals with dress shoes. You need a specialist cobbler who understands the demands of rugged footwear and uses the appropriate materials and adhesives to ensure a safe and durable repair.

Making the Right Choice for Your Gear

Use your boot's construction and condition to guide your decision.

- If your primary focus is extending the life of premium, welted boots: Resoling is an extremely cost-effective and smart choice that honors the original craftsmanship.

- If your primary focus is repairing modern, cemented-sole boots: Get a quote from a specialist cobbler and weigh it carefully against the cost and features of a new pair.

- If you are unsure of your boot's construction: The single most important step is to take them to an experienced cobbler for a professional assessment before making any decision.

By understanding how your boots are made, you can confidently decide whether to repair or replace them, ensuring you get the maximum value and safety from your gear.

Summary Table:

| Boot Construction Type | Resole Feasibility | Key Consideration |

|---|---|---|

| Goodyear Welt / Stitched | Excellent | Designed for multiple resoles; most durable and repair-friendly. |

| Cemented | Possible (with a specialist) | Process is more difficult and less reliable; depends on cobbler's skill. |

| Molded (One-Piece) | Generally Not Repairable | Sole and upper are a single unit; replacement is the only option. |

Extend the life of your motorcycle gear with 3515, a large-scale manufacturer.

As a leading producer for distributors, brand owners, and bulk clients, we understand the importance of durability and value. Our comprehensive production capabilities encompass all types of footwear, including boots built for longevity and performance.

Looking for reliable, well-constructed footwear for your customers? Contact our team today to discuss your manufacturing needs and how we can deliver quality that lasts.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- Why is a Cash on Delivery system considered a necessary payment mechanism in the e-commerce distribution of footwear?

- How does specialized biomechanical software assist in defining slip direction along a curved walking path? Guide to Gait

- Why are reflective patches of different geometric shapes used for footwear tracking? Unlock Precise Gait Analysis

- How does styling influence the choice of winter boots? Finding the Perfect Balance for Your Lifestyle

- Why is shaft height important in motorcycle boots? A Critical Factor for Rider Safety

- What is the function of a hydrostatic pressure tester? Evaluate Water Resistance for Nano-Protective Sports Fabrics

- What are the advantages and limitations of needle grippers vs. vacuum cups? Master handling for porous textiles.

- Are chemical toe warmers useful for winter cycling? Beat the Cold and Extend Your Riding Season