In short, not necessarily. While oil is technically a chemical, the "oil-resistant" rating on a safety boot refers to a very specific type of protection. It does not guarantee the boot will protect you from a broad range of other chemicals, such as potent acids, bases, or industrial solvents.

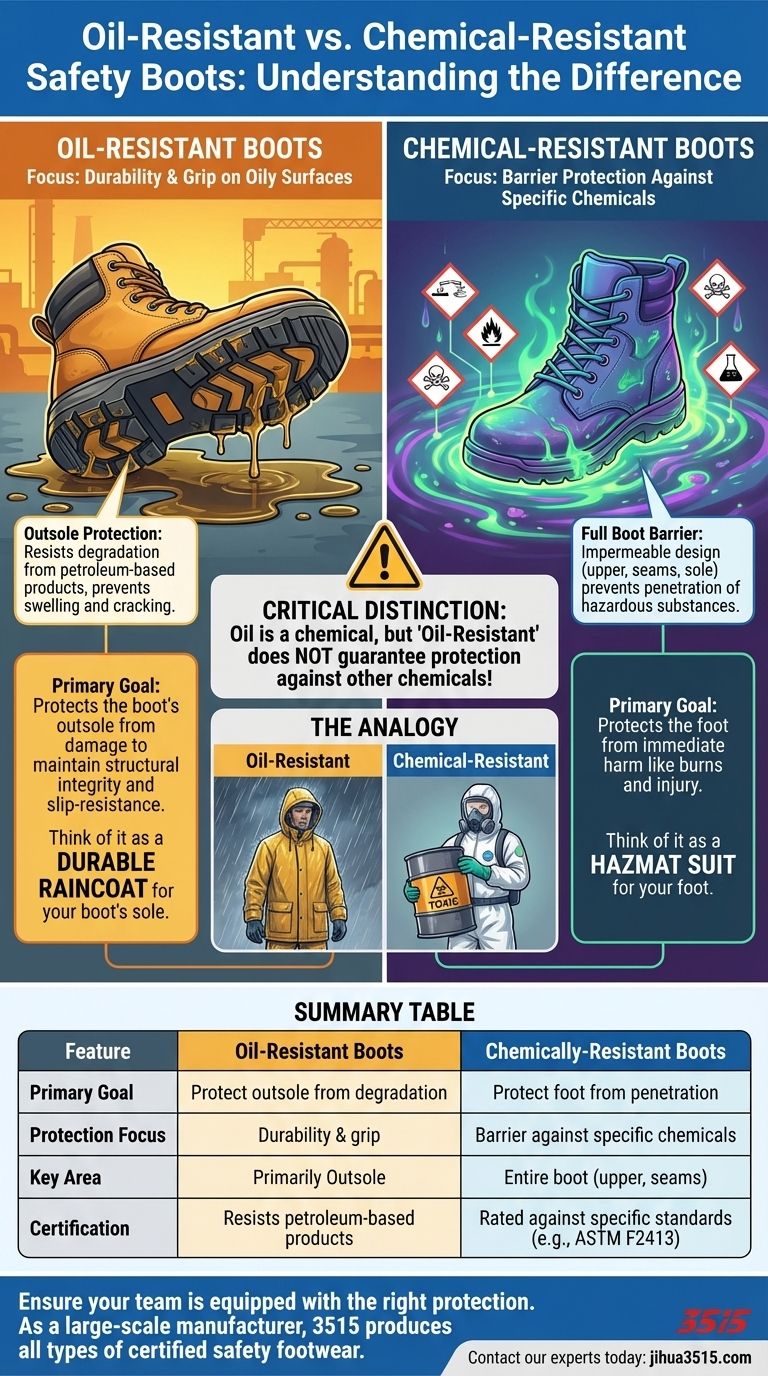

The core distinction is one of purpose: Oil resistance is primarily about protecting the boot's outsole from degrading, while chemical resistance is about protecting your foot from hazardous substance penetration. These are two separate safety features that should not be used interchangeably.

What "Oil-Resistant" Actually Means

It’s About the Outsole

The oil-resistant designation almost always refers to the boot’s outsole. It certifies that the material, typically a specific type of rubber or synthetic compound, will not break down when exposed to petroleum-based products.

The Goal is Durability and Grip

When a standard sole is exposed to oil and grease, it can swell, soften, or crack. This compromises the structural integrity of the boot and can significantly reduce its lifespan and slip-resistance.

An oil-resistant sole maintains its form and durability, ensuring your footwear remains safe and functional in environments like auto garages, manufacturing plants, or oil rigs.

Understanding True Chemical Resistance

A Much Broader Standard

Chemical resistance is a far more comprehensive and critical safety feature. It means the entire boot, including the upper material and seams, is designed to act as an impermeable barrier against specific hazardous liquids.

It's All in the Material

Boots designed for chemical protection are often made from materials like PVC, nitrile, or specialty-treated rubbers. These materials are tested to withstand penetration from a list of specific chemicals for a certain period.

Look for Specific Certifications

True chemical-resistant footwear will be rated against specific safety standards (like ASTM F2413 in the US). These standards explicitly define the level of protection and often list the types of chemicals the boot can safely resist.

The Critical Distinction: Oil vs. Other Chemicals

Why the Confusion Exists

The confusion is understandable because oil is a chemical. However, in the world of personal protective equipment (PPE), the terms address different risks. "Oil resistance" tackles a durability problem, whereas "chemical resistance" tackles a direct human health hazard.

The Danger of Assumption

Assuming your oil-resistant work boots will protect you from a corrosive acid or a solvent is a dangerous mistake. The material may offer no protection at all, allowing the substance to penetrate quickly and cause severe chemical burns or injury.

An Analogy: A Raincoat vs. a Hazmat Suit

Think of an oil-resistant boot like a durable raincoat. It's excellent for its specific purpose—keeping you dry from water.

A chemical-resistant boot, however, is like a hazmat suit. It is designed to provide a total barrier against materials that can cause immediate and severe harm. You would never wear a simple raincoat to handle a toxic spill.

Making the Right Choice for Your Hazard

To ensure your safety, you must match your boot's features to the specific risks of your environment.

- If your primary focus is working with oils, fuels, and grease: An oil-resistant outsole is a critical feature for boot longevity and maintaining reliable traction.

- If your primary focus is handling specific acids, bases, or solvents: You must select a boot explicitly rated as chemical-resistant and confirm it protects against the exact substances you work with.

- If you face a mix of hazards: Look for dual-certified footwear that clearly states it meets standards for both oil resistance and resistance to specific chemical hazards.

Always verify your PPE is rated for the specific hazard you face, not just a general category.

Summary Table:

| Feature | Oil-Resistant Boots | Chemically-Resistant Boots |

|---|---|---|

| Primary Goal | Protect the boot's outsole from degradation | Protect the foot from hazardous substance penetration |

| Protection Focus | Durability and grip on oily surfaces | Barrier against specific chemicals (acids, solvents, etc.) |

| Key Area | Primarily the outsole material | The entire boot, including upper and seams |

| Certification | Resists petroleum-based products | Rated against standards like ASTM F2413 for specific chemicals |

Ensure your team is equipped with the right protection.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oil-resistant and chemically-resistant boots, certified for specific workplace hazards.

We can provide the exact footwear solution you need for durability, chemical safety, or a combination of both.

Contact our experts today for a consultation on your specific requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why are composite-toe boots suitable for composite manufacturing? The Ideal Safety Solution

- What is the process for evaluating job dangers related to footwear? A Guide to Systematic Hazard Assessment

- Why is ankle and arch support important in safety footwear? Prevent Injury & Fatigue

- What are the key differences between EN ISO 20345 and EN ISO 20347 certifications? Choose the Right Footwear for Your Workplace Safety

- What is the application value of lightweight safety shoes? Boost Comfort and Safety in Hybrid Workplaces

- Why is it necessary to balance safety shoe protection with flexibility? Optimize Worker Comfort and Agility

- What are the risks of wearing the wrong safety toe boot? Avoid Catastrophic Injury & Chronic Pain

- What is the correlation between high-standard safety footwear and employee performance? Boost Productivity and Safety