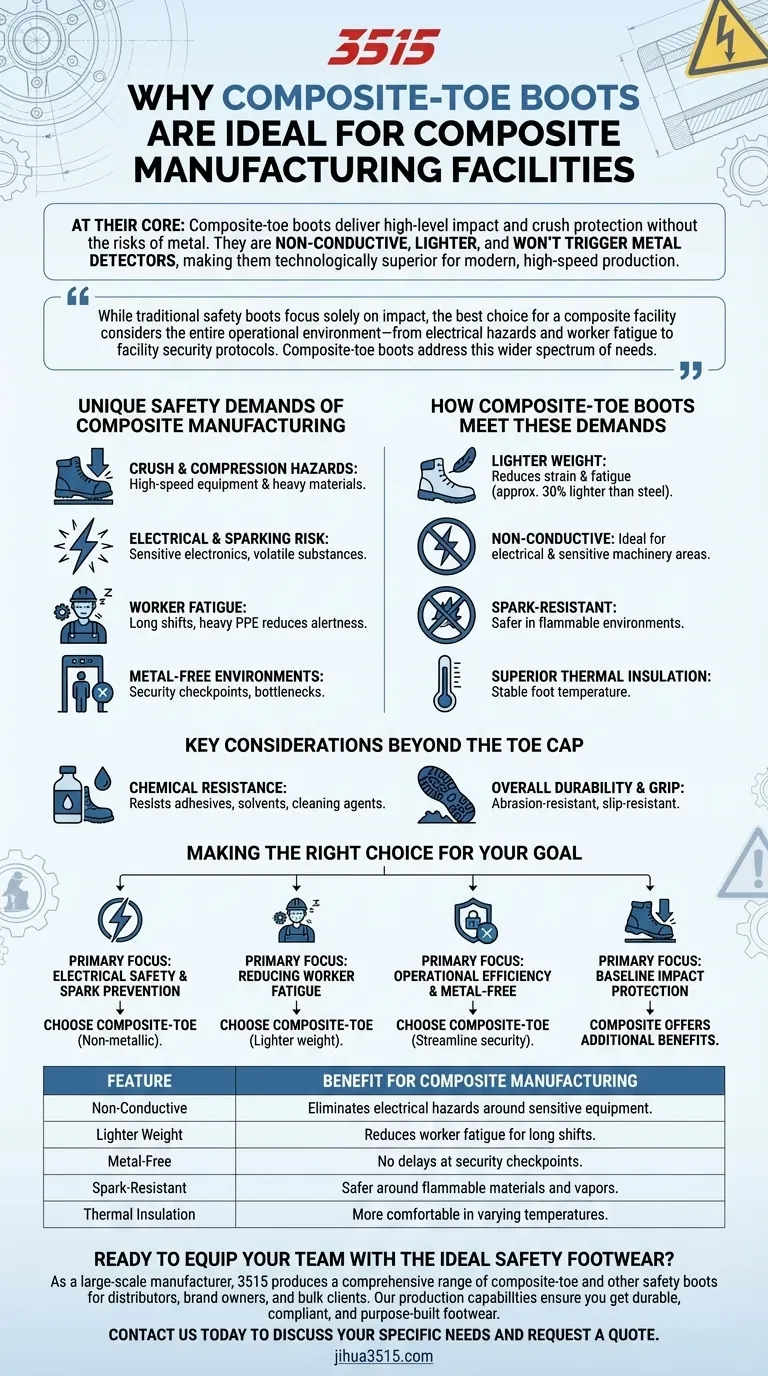

At their core, composite-toe boots are exceptionally suited for composite manufacturing facilities because they deliver the same high-level impact and crush protection as steel toes but eliminate the specific risks and inefficiencies associated with metal. They are non-conductive, lighter, and won't trigger metal detectors, making them a technologically superior choice for modern, high-speed production environments.

While traditional safety boots focus solely on impact, the best choice for a composite facility considers the entire operational environment—from electrical hazards and worker fatigue to facility security protocols. Composite-toe boots address this wider spectrum of needs.

The Unique Safety Demands of Composite Manufacturing

To understand the value of composite toes, we must first recognize that a composite manufacturing facility presents a more complex set of risks than a standard construction site. The required protection goes beyond just preventing crush injuries.

The Baseline: Crush and Compression Hazards

Like any industrial setting, composite manufacturing involves high-speed equipment and heavy materials. Reliable foot protection that meets or exceeds industry safety standards for impact and compression is the absolute minimum requirement.

The Electrical and Sparking Risk

These facilities often use sensitive electronic equipment and may involve volatile substances like adhesives, sealants, or cleaning agents. A boot containing metal introduces the risk of conducting electricity or creating a spark, which can be catastrophic in these environments.

The Factor of Worker Fatigue

Workers in manufacturing often spend entire shifts on their feet, moving constantly. The weight of personal protective equipment (PPE) directly contributes to physical fatigue, which can reduce alertness and increase the likelihood of accidents over a long day.

The Challenge of Metal-Free Environments

Many advanced manufacturing or high-security facilities utilize metal detectors at entry points. Metal-toed footwear creates an operational bottleneck, requiring removal or secondary screening for every worker, every day.

How Composite-Toe Boots Meet These Demands

Composite-toe boots are engineered specifically to overcome the limitations of traditional steel-toe boots in modern industrial settings. They are typically made from materials like Kevlar, carbon fiber, plastic, or fiberglass.

Lighter Weight for Enhanced Comfort

Composite-toe caps are significantly lighter than steel—often by about 30%. This weight reduction directly lessens strain on the wearer, reducing fatigue and improving comfort during extended periods of wear.

Non-Conductive for Electrical Safety

Because they contain no metal, composite-toe boots do not conduct electricity. This inherent property makes them the ideal choice for electricians, engineers, and anyone working near energized circuits or sensitive electronic machinery.

Spark-Resistant Properties

The non-metallic nature of composite materials also means they will not create a spark upon impact with another surface. This is a critical safety feature in any area where flammable materials or vapors may be present.

Superior Thermal Insulation

Metal is an excellent thermal conductor, meaning steel-toe boots can become uncomfortably cold or hot by absorbing the ambient temperature. Composite materials provide far better insulation, keeping the foot temperature more stable and comfortable.

Key Considerations Beyond the Toe Cap

While the toe cap is critical, the entire boot must be suited to the environment. A truly effective safety boot for composite manufacturing incorporates several other key features.

Chemical Resistance

The boot's upper and outsole materials must be able to resist degradation from the specific chemicals used in the facility, such as adhesives, solvents, and cleaning agents. This prevents chemical burns and preserves the structural integrity of the boot.

Overall Durability and Grip

Look for features that enhance the boot's lifespan and performance, such as full-grain leather, abrasion-resistant fabrics, and rugged outsoles with deep treads. A secure grip on potentially slick manufacturing floors is a non-negotiable safety feature.

Making the Right Choice for Your Goal

When selecting footwear, match the boot's primary strengths to your facility's most critical safety priorities.

- If your primary focus is electrical safety and spark prevention: Choose composite-toe boots, as their non-metallic construction is the only way to eliminate these risks.

- If your primary focus is reducing worker fatigue over long shifts: The lighter weight of composite-toe boots provides a distinct advantage for all-day comfort and alertness.

- If your primary focus is operational efficiency in a secure, metal-free site: Composite-toe boots are the clear choice to streamline movement through security checkpoints.

- If your primary focus is baseline impact protection: Both steel and composite toes meet the same safety requirements, but composite offers additional benefits that are highly relevant to a manufacturing environment.

Ultimately, choosing composite-toe footwear is about adopting a safety solution that is as advanced as the environment you work in.

Summary Table:

| Feature | Benefit for Composite Manufacturing |

|---|---|

| Non-Conductive | Eliminates electrical hazards around sensitive equipment. |

| Lighter Weight | Reduces worker fatigue for long shifts. |

| Metal-Free | No delays at security checkpoints. |

| Spark-Resistant | Safer around flammable materials and vapors. |

| Thermal Insulation | More comfortable in varying temperatures. |

Ready to equip your team with the ideal safety footwear for your composite manufacturing facility?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite-toe and other safety boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant, and purpose-built footwear that protects your workforce and enhances operational efficiency.

Contact us today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?