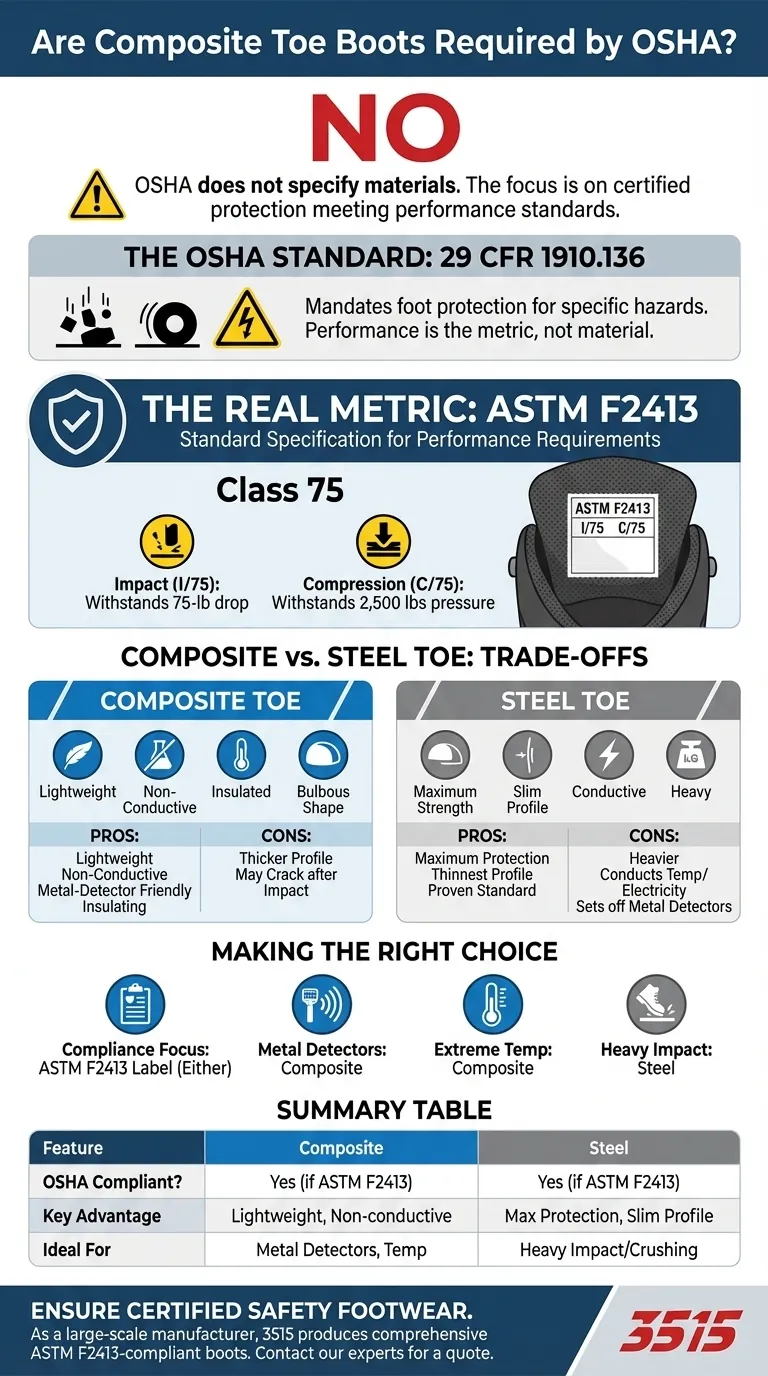

No, OSHA does not specifically require composite toe boots. Instead, OSHA mandates that employers ensure workers use protective footwear that meets a specific performance standard when they are exposed to foot injury risks. As long as a composite toe boot meets that required standard, it is fully compliant.

The core principle of OSHA's rule is about certified protection, not the specific material used in the safety toe cap. Compliance hinges on whether the footwear meets the performance criteria outlined in the ASTM F2413 standard, regardless of it being composite, steel, or alloy.

The OSHA Standard: From Hazard to Protection

OSHA’s regulations on foot protection are designed to be flexible enough to address a wide variety of workplace dangers. The focus is always on the level of protection needed for the specific hazards present.

The Rule is Based on Risk

OSHA standard 29 CFR 1910.136 requires protective footwear in workplaces where there is a danger of foot injuries. This includes risks from falling or rolling objects, objects piercing the sole, or electrical hazards.

The regulation does not name a specific material. It simply states that the footwear must be appropriate for the identified hazard.

Performance is the True Metric

The critical takeaway is that OSHA is concerned with what a boot does, not what it's made of. The agency relies on consensus standards from organizations like ASTM International to define what "protective" actually means in measurable terms.

The Standard That Actually Matters: ASTM F2413

To ensure footwear provides genuine protection, OSHA refers to the criteria established in ASTM F2413, the Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear.

What is ASTM F2413?

This is the current standard that safety footwear must meet to be considered OSHA-compliant. It establishes the minimum requirements for the design, performance, testing, and classification of protective footwear.

If you see a reference to ANSI Z41, that is an older, outdated standard that ASTM F2413 has since replaced.

Decoding the Safety Rating

Compliant boots are tested for both impact and compression resistance. The highest rating is Class 75.

- Impact (I/75): The toe cap can withstand a 75-pound object being dropped from a specified height.

- Compression (C/75): The toe cap can withstand 2,500 pounds of rolling pressure.

A boot that meets these requirements will be permanently marked with this information, typically on the inside of the tongue. This label is your proof of compliance.

Understanding the Trade-offs: Composite vs. Steel

While both materials can be fully OSHA-compliant by meeting the ASTM F2413 standard, they have different properties that make them suitable for different environments.

The Case for Composite Toes

Composite toes are made from non-metal materials like Kevlar, carbon fiber, plastic, or fiberglass. Their primary advantage is that they are lightweight and do not conduct electricity, heat, or cold. This makes them ideal for workers who need to pass through metal detectors or work in extreme temperatures.

The Downside of Composite Toes

To achieve the same strength rating as steel, a composite toe cap must be thicker and more bulbous. After a significant impact, a composite toe may crack, and the boot must be replaced immediately, even if the damage isn't obvious.

The Case for Steel Toes

Steel has been the industry standard for decades for a reason. It provides the maximum protection in the thinnest possible profile. For a given thickness, steel can withstand greater impacts than composite materials.

The Downside of Steel Toes

The main drawbacks of steel are its weight and its conductivity. Steel toe boots are heavier, will set off metal detectors, and will transfer cold or heat far more easily than composite materials.

Making the Right Choice for Your Goal

Your decision should be based on a combination of compliance requirements and the specific needs of your work environment.

- If your primary focus is OSHA compliance: Look for the ASTM F2413 I/75 C/75 rating inside the boot, regardless of whether the toe is composite or steel.

- If your workers pass through metal detectors: Choose composite toe boots to eliminate a daily inconvenience and improve workflow.

- If your environment involves extreme cold or heat: Select composite toes for their superior insulation and improved comfort.

- If your job has a high risk of heavy impact or crushing: Steel toes often provide the most robust protection in the slimmest profile.

Ultimately, choosing the right boot is about matching certified protection to your specific job-site hazards.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| OSHA Compliant? | Yes (if ASTM F2413 rated) | Yes (if ASTM F2413 rated) |

| Key Advantage | Lightweight, non-conductive | Maximum protection, slim profile |

| Ideal For | Metal detectors, extreme temperatures | Heavy impact/crushing hazards |

Ensure your team has the right certified safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant boots for distributors, brand owners, and bulk clients. Whether your priority is lightweight composite toes or robust steel toes, we can deliver the certified protection your workforce needs. Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What is the purpose of steel-toe moc toe boots? Achieve All-Day Safety and Comfort