Yes, composite toe boots are inherently corrosion-resistant. This is one of their primary advantages over traditional steel toe boots. Because they are made from non-metallic materials like carbon fiber, Kevlar, or specialized plastics, they do not contain iron and are therefore completely immune to rust.

The core takeaway is that while both steel and composite toe caps must pass the same ASTM safety standards for impact, the material difference is critical. Composite toes offer complete corrosion resistance and electrical insulation, while steel toes provide maximum strength in a thinner profile.

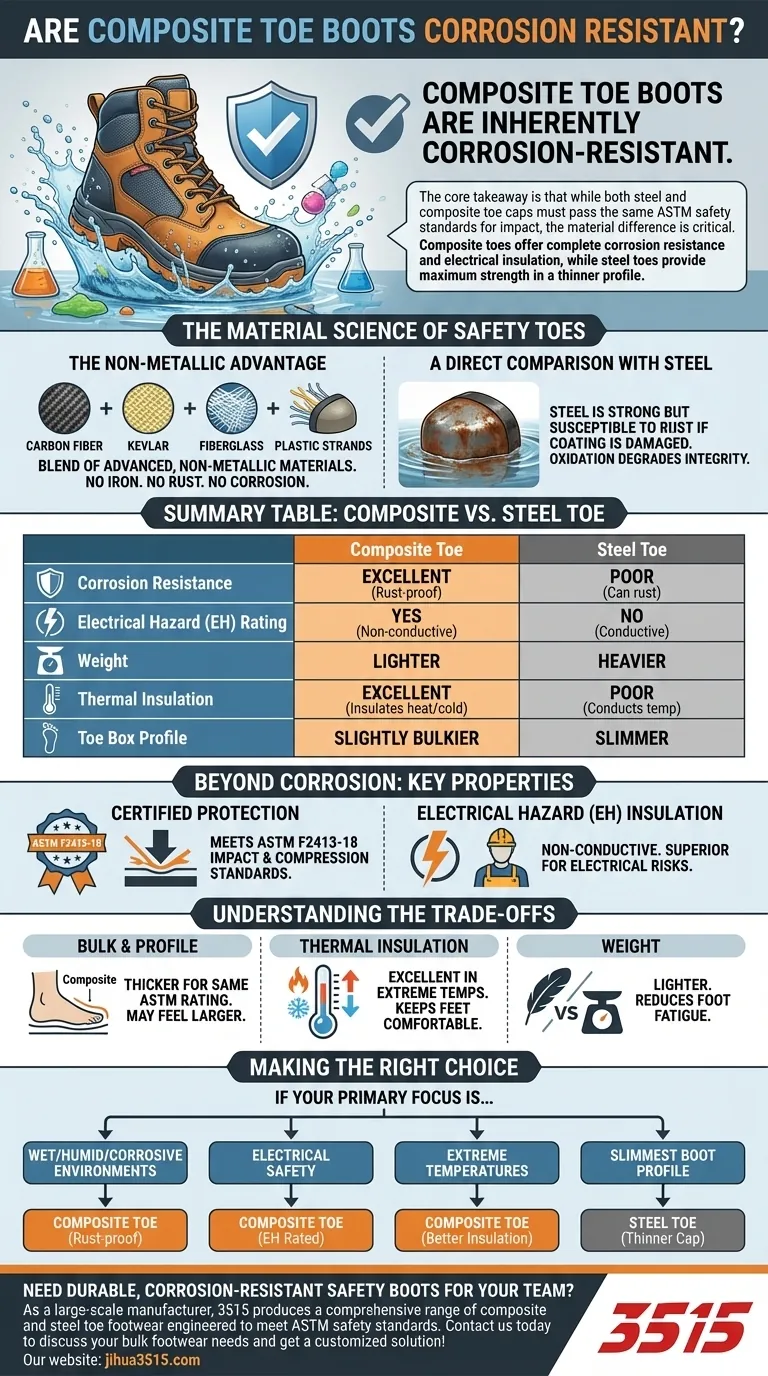

The Material Science of Safety Toes

Choosing the right safety boot goes beyond meeting a basic requirement. It's about understanding how the materials perform in your specific work environment. Corrosion is a significant factor in wet, humid, or chemical-heavy settings.

The Non-Metallic Advantage

Composite safety caps are crafted from a blend of advanced, non-metallic materials. These can include carbon fiber, fiberglass, Kevlar, and high-strength plastics.

The key property here is the complete absence of iron or other metals that oxidize. This means they cannot rust or corrode, regardless of exposure to water, moisture, or common industrial chemicals.

A Direct Comparison with Steel

Steel toe caps are incredibly strong but are susceptible to rust if their protective coating becomes scratched or worn away.

Once moisture reaches the underlying steel, oxidation begins. This can degrade the cap's integrity over time and is a particular concern for those working outdoors, in marine environments, or around corrosive substances.

Beyond Corrosion: Other Key Properties

While corrosion resistance is a major benefit, it's part of a larger safety ecosystem. Composite toes are engineered to meet the same stringent standards as their steel counterparts.

Certified Impact and Compression Protection

All legitimate safety footwear, regardless of material, must meet standards set by organizations like the American Society for Testing and Materials (ASTM).

Composite toe boots are rated to the ASTM F2413-18 standard, meaning they provide the same level of protection against falling objects (impact) and crushing forces (compression) as a certified steel toe boot.

Electrical Hazard (EH) Insulation

A significant advantage of the non-metallic construction is its inability to conduct electricity.

Many composite toe boots carry an Electrical Hazard (EH) rating. This makes them the superior choice for electricians or anyone working in environments with a risk of contact with live electrical circuits.

Understanding the Trade-offs

No single material is perfect for every application. Choosing between composite and steel involves weighing their respective strengths and weaknesses against the hazards of your job.

Bulk and Profile

To achieve the same ASTM impact rating as steel, a composite toe cap must often be slightly thicker and bulkier. This can make the toe box of the boot feel larger, which is a matter of personal fit and comfort.

Thermal Insulation

Composite materials do not conduct temperature well. This is a significant advantage in both extreme cold and hot environments, keeping your feet more comfortable than a steel toe cap, which will readily transfer the ambient temperature.

Weight

Composite toes are generally lighter than steel toes. While the difference may seem minor, it can reduce foot fatigue over the course of a long workday, particularly for those who do a lot of walking.

Making the Right Choice for Your Goal

Ultimately, the decision rests on a clear understanding of your daily work environment and its specific risks.

- If your primary focus is working in wet, humid, or corrosive environments: Composite toes are the superior choice due to their complete immunity to rust.

- If your primary focus is electrical safety: A composite toe boot with an EH rating is the only appropriate option as it does not conduct electricity.

- If your primary focus is working in extreme temperatures: Composite toes offer far better thermal insulation against both heat and cold.

- If your primary focus is finding the slimmest possible boot profile: A steel toe may be preferable, as it can meet safety standards with a thinner cap.

Choosing the right safety toe is about matching the material's inherent properties to the specific hazards you face every day.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Corrosion Resistance | Excellent (Rust-proof) | Poor (Can rust if coating is damaged) |

| Electrical Hazard (EH) Rating | Yes (Non-conductive) | No (Conductive) |

| Weight | Lighter | Heavier |

| Thermal Insulation | Excellent (Insulates against heat/cold) | Poor (Conducts temperature) |

| Toe Box Profile | Slightly bulkier | Slimmer |

Need durable, corrosion-resistant safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite and steel toe footwear for distributors, brand owners, and bulk clients. Our boots are engineered to meet ASTM safety standards and are built to withstand harsh environments—ensuring long-lasting performance and worker safety.

Contact us today to discuss your bulk footwear needs and get a customized solution!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions