Does this scenario sound familiar? You've invested a significant budget in high-quality tactical or combat boots for your team, expecting them to last for years. Yet, months later, you're looking at a pile of them with cracked leather, separated soles, and frayed seams, facing requests for premature replacements. It’s a frustrating cycle that strains budgets and raises questions about product quality.

But what if the boots aren't the problem?

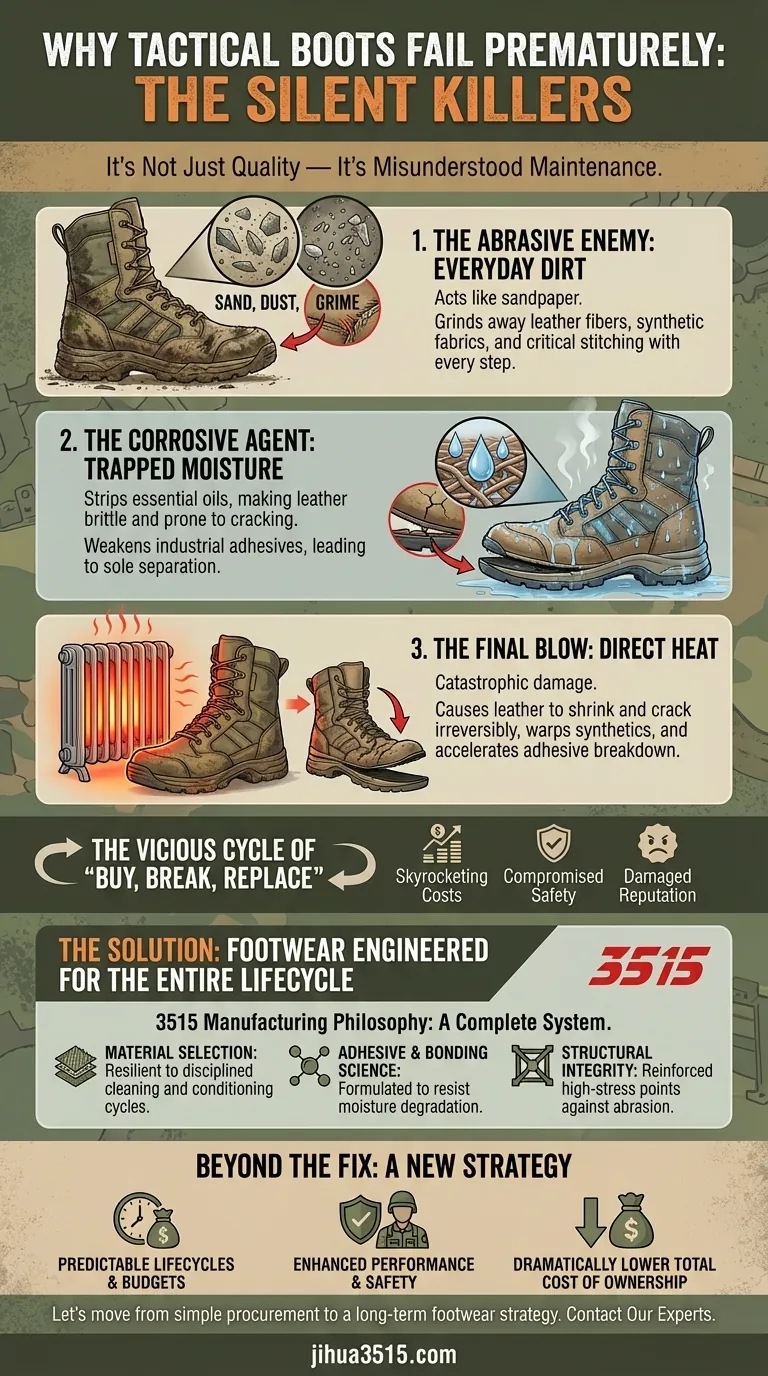

The Vicious Cycle of "Buy, Break, Replace"

When expensive, mission-critical footwear fails, the default assumption is a manufacturing defect. This leads to a costly and inefficient cycle: file a complaint, procure replacements, and hope the next batch fares better. Teams often resort to what seem like logical fixes: issuing stern memos about "taking better care of equipment" or simply budgeting for a higher-than-expected replacement rate.

The commercial consequences are significant and go beyond the simple cost of new boots:

- Skyrocketing Total Cost of Ownership (TCO): Constant replacements obliterate your budget, turning a one-time capital expense into a recurring operational drain.

- Compromised Operational Readiness: A team member with failed footwear in the field is a liability. It's a risk to their safety, comfort, and ability to perform their duties effectively.

- Damaged Reputation: For distributors and brand owners, a reputation for gear that doesn't last leads to customer dissatisfaction, returns, and lost business.

These "solutions" fail because they misdiagnose the problem. The issue isn't a single faulty batch; it's a fundamental misunderstanding of the forces that silently destroy high-performance footwear.

The Real Culprits: Three Silent Killers of Tactical Boots

The true cause of premature boot failure lies in the interaction between the boot’s advanced materials and their environment. Three seemingly harmless factors, when misunderstood, will consistently undermine even the most ruggedly built boot.

1. The Abrasive Enemy: Everyday Dirt

The Common Belief: "It's just a little mud. I'll clean it off this weekend."

The Harsh Reality: Dirt, sand, and dust are not passive grime. They are collections of microscopic, abrasive particles. With every step, these particles grind away at leather fibers, synthetic fabrics, and—most critically—the stitching that holds the boot together. Left unchecked, this constant friction acts like sandpaper, slowly but surely sawing through the boot's structural integrity.

2. The Corrosive Agent: Trapped Moisture

The Common Belief: "They're waterproof. I'll just let them dry out on their own."

The Harsh Reality: Moisture is the arch-nemesis of modern footwear construction. When water soaks into leather, it bonds with the natural oils. As the water evaporates, it draws these essential oils out, leaving the leather brittle and prone to cracking. More importantly, persistent dampness is a solvent for the industrial-strength adhesives used to bond the sole to the upper. It weakens the glue, leading to the dreaded sole separation.

3. The Final Blow: Direct Heat

The Common Belief: "The boots are soaked. I'll put them by the heater to dry them quickly."

The Harsh Reality: This is the single fastest way to destroy a pair of boots. Intense, direct heat is catastrophic. It causes leather to shrink and crack irreversibly. It can warp or even melt synthetic components. And it accelerates the breakdown of adhesives, guaranteeing that the sole will soon part ways with the rest of the boot. The common "fix" of quick-drying is, in fact, an act of destruction.

Trying to solve this problem by simply buying more boots is like trying to fix a leaky pipe by buying more buckets. You're managing the symptom, not curing the disease.

The Solution: Footwear Engineered for the Entire Lifecycle

A true solution doesn't just involve buying a "tough" boot. It involves investing in footwear that is designed from the ground up for durability, performance, and maintainability. The right boot is one built with an understanding of the challenges it will face not just in the field, but in the maintenance locker afterward.

This is where our manufacturing philosophy at 3515 makes a critical difference. We don't just assemble footwear; we engineer a complete system.

- Material Selection: We utilize leathers, synthetics, and textiles chosen not only for their field performance but for their resilience to disciplined cleaning and conditioning cycles.

- Adhesive and Bonding Science: Our construction methods use industrial-grade adhesives and bonding techniques specifically formulated to resist the degrading effects of moisture when boots are dried correctly.

- Structural Integrity: Our stitching patterns and construction designs reinforce the high-stress points that are most vulnerable to the abrasive effects of dirt and debris.

Our boots are not just built to be used; they are built to be maintained. They are the physical embodiment of the solution—a tool designed to thrive within a system of proper care.

Beyond the Fix: A New Strategy for Footwear Management

When you pair expertly manufactured footwear with a clear understanding of its maintenance needs, the entire dynamic changes. The cycle of "buy, break, replace" ends, and a new set of possibilities opens up.

- Predictable Lifecycles and Budgets: You can accurately forecast the service life of your footwear, transforming your budget from a reactive expense into a predictable investment.

- Enhanced Performance and Safety: Your teams are always equipped with reliable, structurally sound footwear, boosting their effectiveness, morale, and safety in any environment.

- Dramatically Lower Total Cost of Ownership: By extending the life of each pair and drastically reducing the replacement rate, you maximize the return on your initial investment.

This shifts your focus from constantly managing a problem to leveraging a reliable asset.

Your footwear shouldn't be a recurring headache. It should be a dependable foundation for your team's success. By understanding the true reasons for failure, you can implement a strategy that protects your people and your budget. We build the boots designed to make that strategy a success.

Let's move the conversation from simple procurement to a long-term footwear strategy that lowers costs and enhances performance. To discuss your organization's unique requirements, Contact Our Experts.

Visual Guide

Related Products

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

Related Articles

- Your Tactical Boots Are Failing. It’s Not Your Team's Fault.

- The Procurement Officer's Gamble: Why 'Tough Enough' Isn't Good Enough for Tactical Boots

- Beyond the Pattern: The Engineering That Separates True Tactical Boots from Costly Imitations

- The Hidden Cost of 'Good Enough': Why Your Tactical Footwear Fails and How to Fix It for Good

- The 'One-Boot-Fits-All' Fallacy: Why Your Tactical Footwear Isn't Selling—And How to Fix It