You’ve sourced a new line of tactical boots. They have the aggressive tread, the right height, and the perfect camouflage pattern. They look exactly like what your customers expect. But a few months after launch, the reports start trickling in: complaints of aching feet after a short hike, photos of soles peeling away from the upper, or worse, feedback from a bulk client about equipment failure during a critical training exercise.

Your promising new product is quickly becoming a liability, damaging your brand’s reputation one return at a time. Sound familiar?

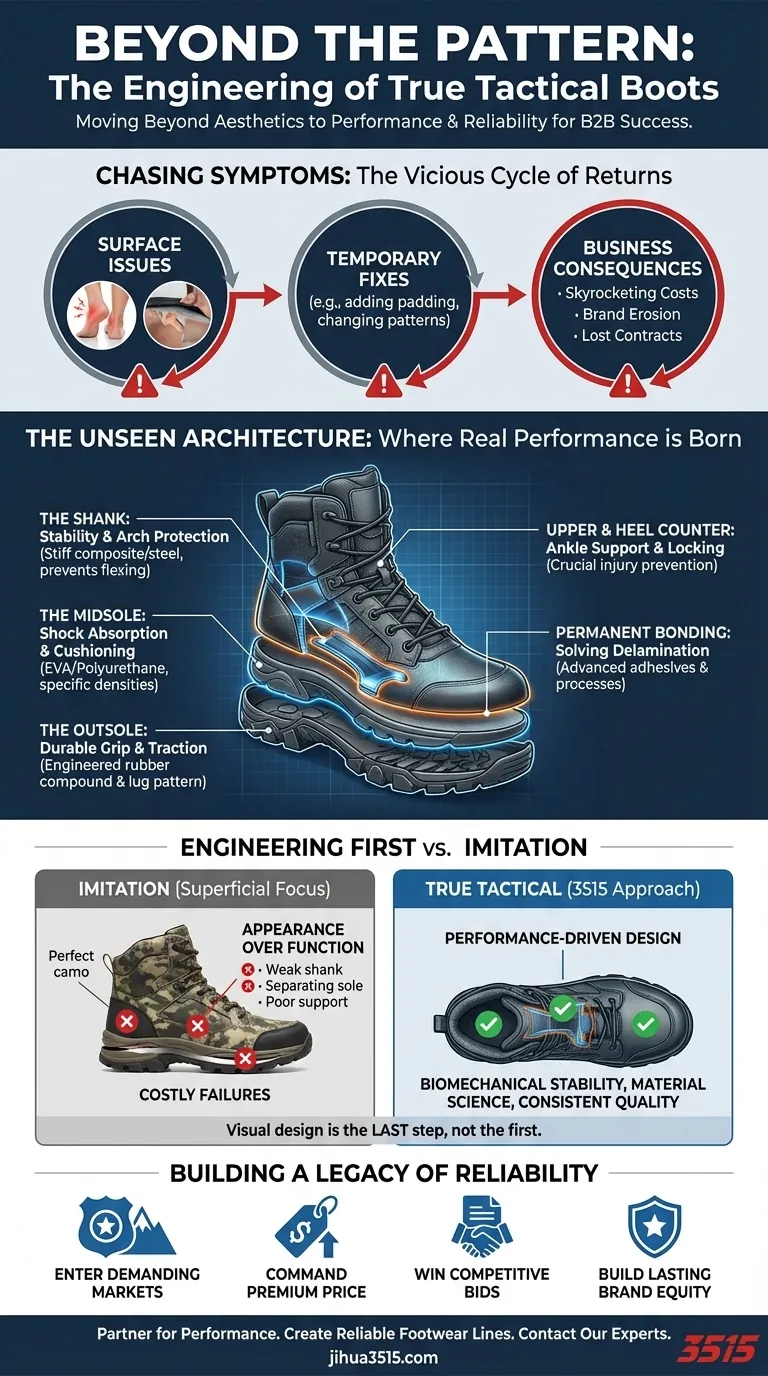

Chasing Symptoms: The Vicious Cycle of Returns and Reputation Damage

This scenario is frustratingly common in the tactical footwear market. For many brand owners and distributors, the immediate reaction is to treat the symptoms. Perhaps you switch to a supplier who offers a boot with a slightly different pattern, or you request more padding in the collar, believing it’s a comfort issue.

But these are temporary fixes for a much deeper problem. The cycle continues, leading to significant business consequences:

- Skyrocketing Costs: Every return, warranty claim, and replacement shipment directly erodes your profit margins.

- Brand Erosion: Customers who experience a product failure don't just return the boots; they lose trust in your brand. In the age of online reviews, a reputation for poor quality can be difficult to shake.

- Lost Contracts: For bulk clients in law enforcement, private security, or government contracting, equipment reliability is non-negotiable. A single product failure can jeopardize a multi-year contract and close the door on future opportunities.

You’re stuck in a loop of solving surface-level issues, all while the fundamental flaw remains unaddressed.

The Unseen Architecture: Where Real Performance is Born

Here is the critical turning point: The performance of a tactical boot is not defined by its color or pattern. Performance is engineered into its unseen architecture.

The real work of a boot happens at a biomechanical level. It must act as a stable platform to support the ankle and foot while carrying heavy loads over unpredictable terrain. It needs to absorb shock, provide torsional rigidity to prevent sprains, and offer a durable grip that won't fail under stress.

This is achieved through a system of carefully chosen materials and structural components:

- The Shank: A stiff piece of material (like steel or composite) embedded in the midsole that prevents the boot from flexing in the wrong places, protecting the arch of the foot from strain and sharp objects.

- The Midsole: The primary layer for shock absorption, often made from EVA or polyurethane foams with specific densities to balance cushioning and stability.

- The Outsole: The point of contact with the ground, requiring a durable rubber compound and a lug pattern engineered for grip, not just aesthetics.

- The Upper and Heel Counter: The components that lock the foot in place, providing the crucial ankle support needed to prevent injury.

The common "solutions"—like adding padding or changing the camo pattern—fail because they are like repainting a car with a cracked engine block. They ignore the boot's fundamental engineering. A boot with a flawless camouflage pattern but a weak shank and a poorly bonded sole is, by definition, a failed product.

Engineering First: Building Boots That Perform, Not Just Appear

To break the cycle of failure and build a truly reliable product, you need a manufacturing partner who understands that the visual design is the last step, not the first. The solution is to prioritize the boot's core construction above all else.

This is where our expertise at 3515 becomes your strategic advantage. We don't just assemble footwear; we engineer performance from the inside out.

- Targeting the Root Cause of Instability: Our designs are built around biomechanical principles, ensuring the ankle support, torsional rigidity, and arch protection are integrated into the boot's core structure. This directly prevents the common field injuries and fatigue that plague lesser boots.

- Solving Material Failure: We leverage our deep knowledge of material science to select the right polymers, adhesives, and composites. This means creating outsoles that withstand abrasion and soles that remain permanently bonded to the upper, eliminating the costly delamination issues that lead to returns.

- Delivering Consistent Quality at Scale: Our advanced manufacturing processes ensure that every single boot meets the exact same engineering specifications. The 10,000th pair is just as reliable as the first, giving you the consistency needed to build a trustworthy brand.

Only after this foundation of performance is perfected do we apply the aesthetic elements, including the precise camouflage pattern your market demands. We treat the pattern as the critical finishing touch on an already high-performance machine.

From Mitigating Risk to Building a Legacy of Reliability

When you partner with a manufacturer who gets this right, the conversation changes. You stop worrying about managing returns and start focusing on growth. Resolving the core engineering problem unlocks new potential for your business.

You can now confidently:

- Enter More Demanding Markets: Approach clients in specialized fields like law enforcement or high-end outdoor recreation who scrutinize performance and test equipment to its limits.

- Command a Premium Price: Justify a higher price point because your product's quality and durability are demonstrable, not just implied by a pattern.

- Win Competitive Bids: Provide bulk clients with footwear that measurably improves user safety and operational effectiveness, making your bid the most compelling choice.

- Build Lasting Brand Equity: Forge a reputation for uncompromising quality and reliability that turns first-time buyers into loyal customers.

Your brand's reputation is built from the ground up, starting with the quality of your products. Don't let a superficial focus on aesthetics undermine your promise to your customers. If you're ready to move beyond imitation and deliver footwear with engineered performance at its core, our team is here to help. We partner with brand owners and large-scale distributors to create footwear lines that are as reliable as they are visually striking. Let's discuss the specific performance requirements for your next project. Contact Our Experts.

Visual Guide

Related Products

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

Related Articles

- Why Even the Best Tactical Boots Fail—And How to Choose the Right Ones

- Beyond the Spec Sheet: The Real Reason Your Tactical Footwear Fails in the Field

- Why Your Tactical Boots Keep Failing—And Why 'Tougher' Isn't the Answer

- The 'Toughness' Trap: Why Choosing the Wrong Tactical Boot Undermines Team Performance

- Mission-Ready From Day One: Why the Tactical Boot "Break-In" Period Is a Sign of Outdated Design