It’s the call every distributor, brand manager, or procurement officer dreads. A major order of 10,000 tactical boots, delivered just months ago, is failing in the field. Zippers are jamming. Eyelets are popping out. Worse, soles are separating from the upper under routine stress. Now, a multi-million dollar contract is at risk, your brand’s reputation is on the line, and end-users are left with gear they can’t trust.

This isn't a hypothetical scenario; it's a costly reality for many who source high-volume tactical footwear. But why does it happen so often, even when the boots looked and felt tough during the selection process?

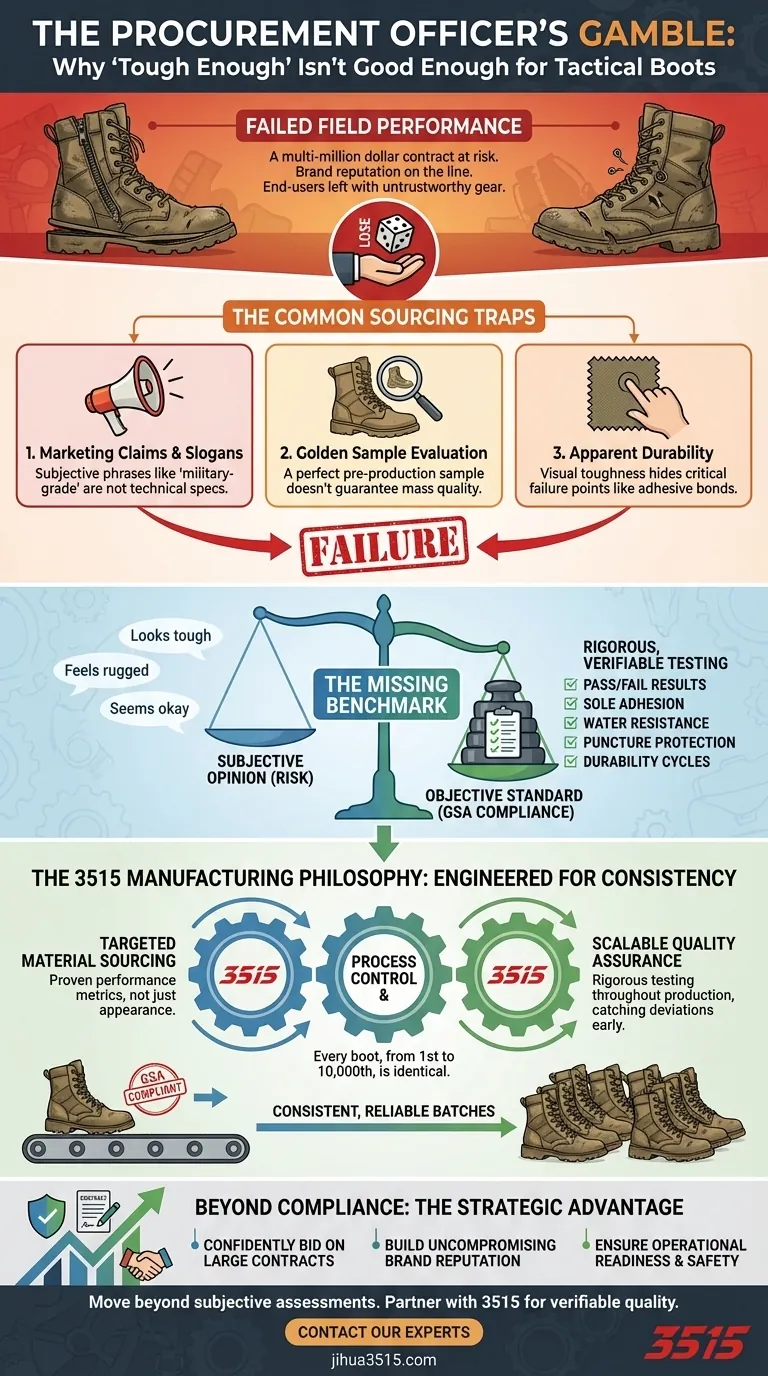

The Common Sourcing Traps: Why Good Intentions Lead to Bad Gear

When faced with sourcing tactical boots, most decision-makers follow a logical, yet flawed, process. They rely on a combination of three things:

- Brand Reputation & Marketing Claims: They choose a supplier based on their market presence or compelling slogans like “military-grade” or “battle-tested.”

- Sample Evaluation: They approve a production run based on the impressive quality of a few pre-production samples.

- Apparent Durability: They select boots made from materials that look and feel rugged, like thick leather or heavy-duty nylon.

The problem is that none of these indicators guarantee performance at scale. Marketing language is not a technical specification. A perfect "golden sample" doesn't ensure that the 5,000th pair off the assembly line will meet the same standard. And the visual toughness of a material says nothing about the quality of the stitching, the durability of the adhesive, or its resistance to environmental wear.

The business consequences are severe. A single bad batch can lead to massive return costs, breach of contract penalties, and irreparable damage to your reputation with government or institutional clients. You waste months on a procurement cycle only to end up back at square one, with less budget and less trust.

The Root of the Problem: The Missing Benchmark for 'Tough'

The core issue isn't a lack of good boots on the market. The root of the problem is the absence of a shared, objective, and verifiable standard for what "tough" actually means.

Without a common benchmark, every sourcing decision becomes a gamble. You are forced to translate subjective marketing into a procurement decision, hoping your interpretation matches reality. The “common solutions” fail because they are based on opinion, not evidence:

- Marketing claims fail because they are not standardized or audited.

- Sample testing fails because it doesn't account for the inevitable variations in large-scale production.

- Visual inspection fails because the most critical failure points—like the chemical bond of the sole—are invisible to the naked eye.

To solve this problem permanently, you need to stop guessing what quality looks like and start measuring it against an established, rigorous standard. You need a system designed to verify performance, not just promise it.

This is precisely the role of GSA (General Services Administration) compliance. It’s not just another label; it’s the objective benchmark the industry needs. GSA compliance means a boot has been subjected to a battery of standardized tests for everything from sole adhesion and water resistance to puncture protection and durability over thousands of flexes. It transforms the abstract idea of "quality" into a concrete, pass/fail result.

The Solution: From a Standard to a Manufacturing Philosophy

To truly de-risk your procurement, you need more than just a boot that passed a one-time test. You need a manufacturing partner whose entire process is built to deliver that level of quality consistently, across every single pair in a 10,000-unit order.

This is where 3515’s expertise becomes your strategic advantage. We don’t just manufacture boots that can pass a GSA test; we have engineered our production lines and quality control systems around the very principles that the GSA standard represents.

- Targeted Material Sourcing: We source materials that are proven to meet specific performance metrics, not just look the part.

- Process Control: Our assembly methods are standardized to ensure the bond strength, stitch integrity, and overall construction of the 10,000th boot is identical to the first.

- Scalable Quality Assurance: We implement rigorous testing throughout the production run, catching deviations long before they become a field problem.

Our capability isn't just a product; it's a system designed to solve the root cause of procurement failure. It provides the verifiable assurance that your investment is sound and your end-users are equipped with footwear that performs as promised.

Beyond Compliance: Building a Reputation on Reliability

Once you eliminate the guesswork and risk from your footwear supply chain, you unlock significant new potential.

Suddenly, you can bid on large-scale government and institutional contracts with confidence, knowing your product is backed by a verifiable standard. Brand owners can build a loyal following based on a reputation for uncompromising reliability, justifying premium positioning. Procurement managers can fulfill their duty of care, ensuring their personnel are safe, effective, and equipped for the mission.

You're no longer just buying boots. You're investing in operational readiness and building a brand promise that you can consistently keep.

The challenge of sourcing high-performance tactical footwear at scale is complex, but the solution is clear. It requires moving beyond subjective assessments and embracing an objective standard for quality, supported by a manufacturing partner who can deliver on that standard every time. If your organization's success depends on the reliability of the gear you provide, let's discuss how our manufacturing expertise can become your greatest asset. Contact Our Experts to start the conversation.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

Related Articles

- The Versatility Trap: Why Your "Do-It-All" Tactical Boot Is Failing Your Customers

- Why Most Tactical Boots Fail: It’s Not the Durability, It’s the System

- Why Even the Best Tactical Boots Fail—And How to Choose the Right Ones

- Tactical vs. Combat Boots: How the Wrong Choice Is Costing Your Organization

- Beyond the Spec Sheet: The Real Reason Your Tactical Footwear Fails