It’s the feedback every footwear brand manager or distributor dreads. A customer leaves a three-star review: “These boots are tough as nails, but after a 10-hour shift, my feet are destroyed.” Or worse, a one-star review: “Supposed to be lightweight, but they offered zero support and fell apart after two months of real work.”

Your team followed the spec sheet. You requested durability, protection, and comfort. Yet, the final product forces your end-users into an impossible compromise. This isn't just a product issue; it's a business problem that shows up as negative reviews, high return rates, and a damaged brand reputation.

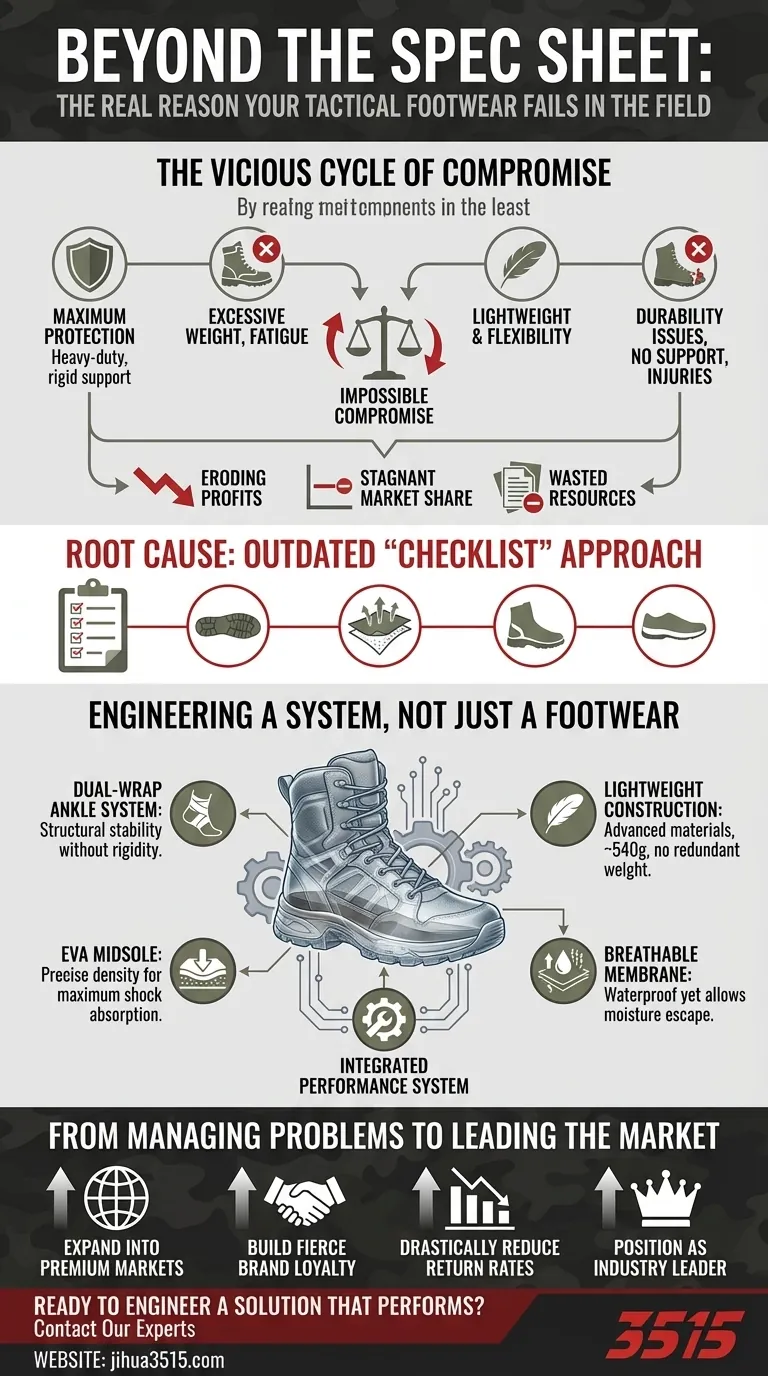

The Vicious Cycle of Compromise

For many brands, sourcing high-performance tactical footwear feels like a constant balancing act on a knife's edge.

You commission a boot built for maximum protection—heavy-duty construction, rigid ankle support—and the feedback rolls in about excessive weight and fatigue. Your customers are security guards, construction workers, and tactical operators who are on their feet all day. A boot that feels like a concrete block, no matter how protective, is a failure for them.

So, you adjust. You prioritize lightweight materials and flexibility. The initial feedback is positive, but then the durability issues surface. Seams split, soles wear out prematurely, and—most critically—the footwear fails to provide the necessary support on challenging terrain, leading to potential injuries.

This cycle has significant business consequences:

- Eroding Profits: Every return and warranty claim directly impacts your bottom line.

- Stagnant Market Share: Your brand becomes known as "good, but..." This "but" prevents you from penetrating premium markets where reliability is non-negotiable.

- Wasted Resources: Your team spends more time managing complaints and logistics than focusing on growth and innovation.

You're left wondering: is it truly impossible to create a boot that is both robustly protective and genuinely comfortable for all-day wear?

The Root of the Problem: A "Checklist" Approach to Design

The answer is no, it's not impossible. The problem isn't the boot; it's the outdated manufacturing philosophy behind it.

Most sourcing processes treat boot features like a checklist. You request a slip-resistant outsole, a waterproof membrane, ankle support, and a cushioned midsole. The manufacturer sources these individual components and assembles them. The result is a collection of parts, not an integrated system.

This is why the common "solutions" fail. They address symptoms, not the underlying cause.

The truth is, these features are often in direct opposition. A rigid, protective structure generates significant impact shock with every step. A soft, cushioned midsole absorbs that shock but can compromise stability. Simply adding a "tougher" material or a "softer" foam doesn't solve this conflict; it just shifts the problem elsewhere. The failure lies in treating the boot as a list of components rather than engineering it as a single, cohesive performance system.

Engineering a System, Not Just a Boot

To break the cycle of compromise, you need a manufacturing partner that understands how these elements must work in harmony. The solution isn't in a single feature, but in the intelligent integration of materials and design.

This is a fundamentally different approach. It's about engineering a system where each component enhances the others.

-

Solving the Shock vs. Stability Conflict: Instead of just using any generic foam, we engineer an EVA (ethylene vinyl acetate) midsole with the precise density to absorb maximum impact. This cushioning is then complemented by a dual-wrap ankle system that provides the structural stability the foam alone cannot, preventing twists and sprains without adding unnecessary rigidity underfoot.

-

Achieving Durability Without Weight: Protection doesn't have to mean heavy. By using advanced construction techniques and material science, we create boots that offer comprehensive protection while weighing as little as 540g. This isn't just about choosing lighter materials; it's about designing a structure where every element contributes to strength, eliminating redundant, heavy components.

-

Delivering True All-Weather Performance: A waterproof boot that doesn't breathe is a failure in warm conditions. Our expertise lies in integrating high-performance waterproof yet breathable membranes that are seamlessly bonded to the boot's upper. This ensures feet stay dry from outside rain and inside perspiration, a critical factor for long-term foot health and comfort.

This systems-based philosophy is what turns a list of specs into a genuinely high-performance product that your customers will trust, shift after shift.

From Managing Problems to Leading the Market

When you solve the core conflict between protection and comfort, you don't just reduce customer complaints; you unlock new potential for your brand.

Imagine launching a product line with the confidence that it will not only meet but exceed the expectations of the most demanding users. You can stop worrying about negative reviews and start building a reputation for uncompromising quality and reliability. This allows you to:

- Expand into premium markets that were previously out of reach.

- Build fierce brand loyalty from professionals who depend on their gear.

- Drastically reduce return rates, directly boosting your profitability.

- Position your brand as an industry leader, setting a new standard for performance footwear.

You can finally stop making compromises and start delivering the footwear your customers have always needed.

If you're ready to move beyond the spec sheet and deliver a superior product that strengthens your brand and grows your business, our team is here to help. We specialize in engineering and manufacturing footwear systems designed for the real-world demands of your customers. Let's discuss the specific challenges your brand is facing and build a solution that performs. Contact Our Experts.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

Related Articles

- Beyond the Spec Sheet: The Real Reason Your Tactical Footwear Fails

- Why Even the Best Tactical Boots Fail—And How to Choose the Right Ones

- Why Most Tactical Boots Fail: It’s Not the Durability, It’s the System

- The Versatility Trap: Why Your "Do-It-All" Tactical Boot Is Failing Your Customers

- Why Your ‘Best’ Tactical Boots Are Failing Your Team—And How to Fix Your Footwear Strategy