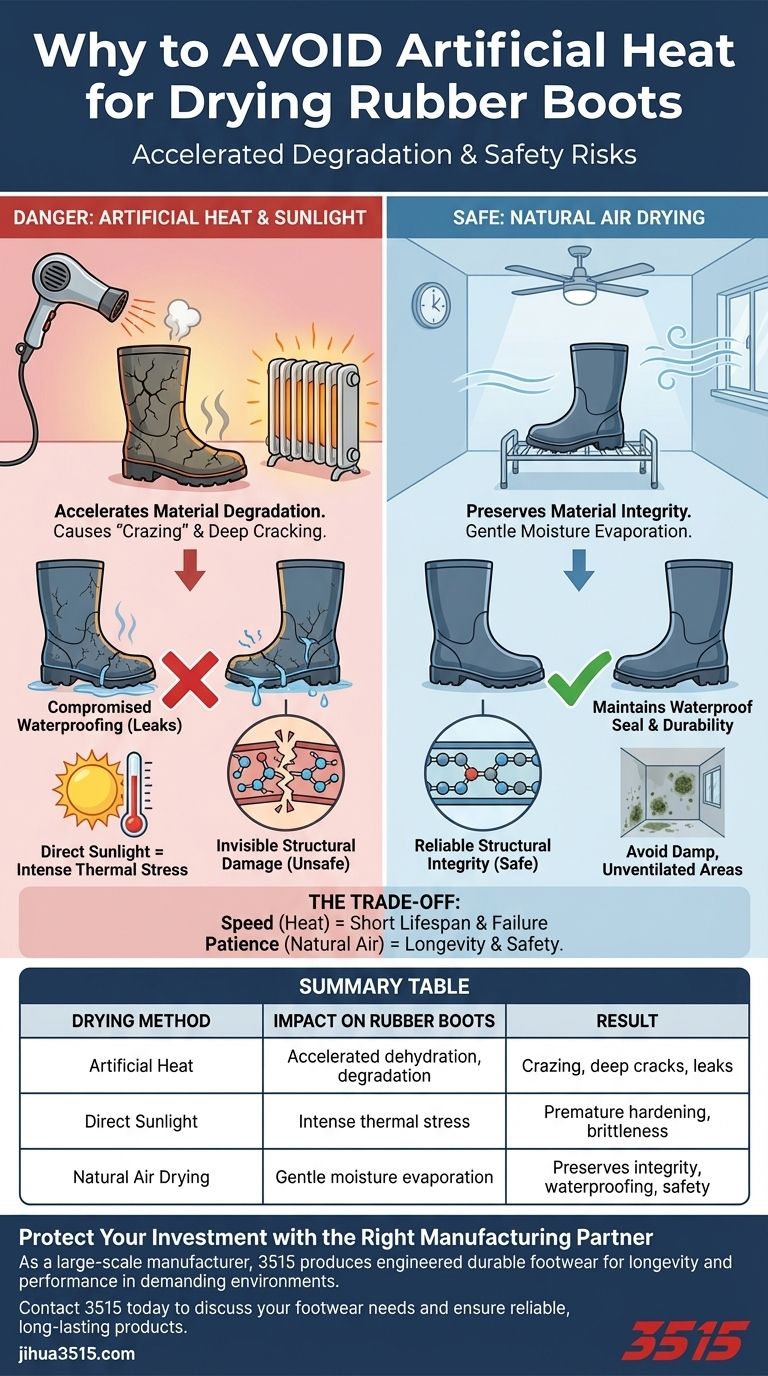

Artificial heat sources accelerate material degradation, causing rubber boots to dry out too aggressively. This rapid dehydration leads to "crazing" and deep cracking, which permanently destroys the boot's waterproof seal and structural integrity.

While artificial heat offers speed, it alters the material composition of the boot, rendering it brittle and unsafe. To maintain waterproof protection and durability, natural air drying is the only viable method.

The Mechanics of Material Failure

Compromised Waterproofing

Rubber boots function as a continuous, impermeable barrier against moisture.

Introducing artificial heat creates crazing, a network of fine cracks across the surface of the material.

Once these micro-fractures appear, the boot can no longer guarantee waterproof protection, causing leaks during future use.

Invisible Structural Damage

Not all heat damage is immediately visible to the naked eye.

Extreme heat degrades the material composition at a molecular level, even if the exterior looks intact.

This invisible weakening makes the boots unsafe for use in hazardous environments where foot protection is critical.

Understanding the Trade-offs

The Cost of Convenience

Using a radiator, hair dryer, or heater is often a reaction to the need for dry gear immediately.

However, you are making a distinct trade-off: saving time now at the expense of the asset's lifespan.

This "efficiency" leads to premature hardening and material failure, forcing you to replace expensive gear more frequently.

Environmental Risks

Heat damage is not limited to mechanical heaters; direct sunlight creates the same destructive effect and must be avoided.

Conversely, avoiding heat does not mean storing boots in damp, unventilated areas.

Damp environments encourage degradation from the inside out; the goal is a balance of dry air without thermal stress.

Making the Right Choice for Your Gear

To ensure your equipment remains reliable and safe, apply the following drying protocols:

- If your primary focus is longevity: Dry boots naturally at room temperature to prevent the material from hardening, shrinking, or cracking.

- If your primary focus is safety: Regularly inspect your boots for signs of crazing, as this indicates the material composition has already been compromised by heat.

Patience during the maintenance process is the single most important factor in preserving the integrity of your footwear.

Summary Table:

| Drying Method | Impact on Rubber Boots | Result |

|---|---|---|

| Artificial Heat (Radiator, Hair Dryer) | Accelerated dehydration, material degradation | Crazing, deep cracks, loss of waterproof seal |

| Direct Sunlight | Intense thermal stress, similar to heaters | Premature hardening, brittleness, structural failure |

| Natural Air Drying | Gentle moisture evaporation at room temperature | Preserves material integrity, waterproofing, and safety |

Protect Your Investment with the Right Manufacturing Partner

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and rubber boots, engineered for longevity and performance in demanding environments.

Don't let improper care shorten the life of your gear. Partner with a manufacturer who understands material science and builds durable protection from the ground up.

Contact 3515 today to discuss your footwear needs and ensure your clients receive reliable, long-lasting products.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

People Also Ask

- What are the UK sizes and corresponding insole lengths for children's wellies? A Simple Sizing Guide

- What are some outdoor activities kids can enjoy while wearing wellies? Unleash All-Weather Fun!

- What alternative boot types are mentioned for wet and muddy conditions? Find the Best Fit for Your Needs

- Should you size up in Wellington boots? A Guide to the Perfect Fit for Any Condition

- What are the key considerations when choosing wellies for babies and toddlers? Ensure Safety and Comfort for Active Play

- When should one wear gardening boots? Ensure Safety and Comfort in Wet, Muddy Conditions

- What are the advantages of PVC wellington boots? Discover the Perfect Blend of Affordability & Waterproofing

- How can customers get help or advice about wellington boot products? Get Expert Guidance for the Perfect Fit