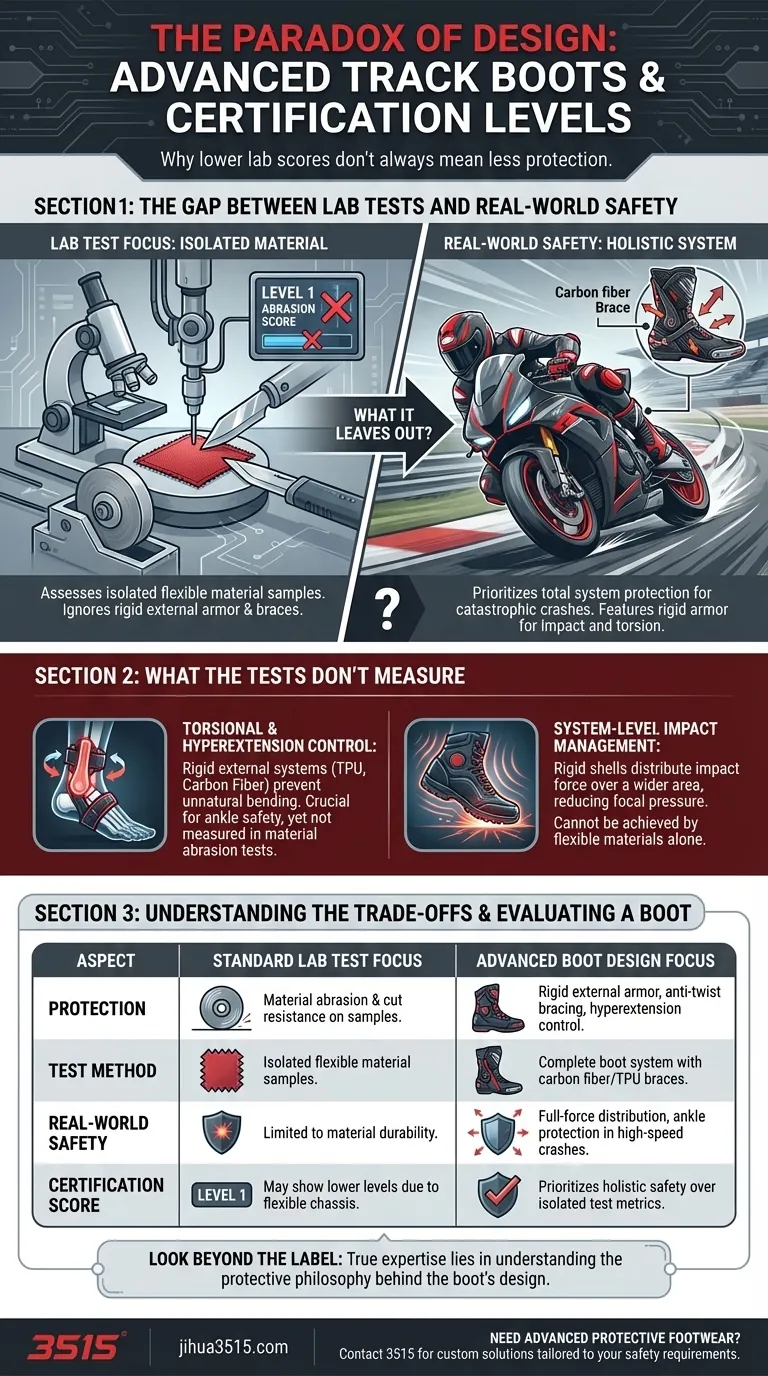

It's a paradox of design: advanced track boots can have lower certification levels in some specific tests precisely because their most advanced protective features are not measured by those tests. Standardized lab tests for abrasion or cutting often assess isolated samples of the boot's flexible upper material, completely ignoring the rigid external structures like carbon fiber braces that provide the highest level of protection in a real-world crash.

The core issue is the gap between standardized material testing and holistic, real-world performance. A lower score on a specific lab test for a boot's fabric does not mean the boot's overall protective system—including its rigid armor—is inferior.

The Gap Between Lab Tests and Rider Safety

To make an informed choice, you must understand what a certification label truly represents and, more importantly, what it leaves out. The numbers tell a part of the story, not the whole story.

How Certification Tests Are Designed

The prevailing standard for motorcycle boots, EN 13634, is designed to create a repeatable, fair benchmark. It breaks down protection into key categories, such as impact abrasion, cut resistance, and transverse rigidity.

To ensure consistency, some of these tests must be performed on standardized samples of a material, not the fully constructed, multi-layered boot.

The "Material Sample" Limitation

This is the central reason for the discrepancy. Tests for impact abrasion and cut resistance are often conducted on the primary material used in the boot's upper.

This method effectively measures the quality of the microfiber, leather, or textile itself. It completely disregards the protective value of any external armor or bracing layered on top of it.

Why Rigid Structures Are Ignored

Think of it like testing the strength of a single brick instead of the entire reinforced wall. The test is valid for the brick, but it tells you nothing about the performance of the complete system.

A high-end race boot might use a more flexible, comfortable material for the main chassis and then overlay a massive carbon fiber anti-torsion brace. The test only grades the flexible material, leading to a potentially lower score, while ignoring the feature that will actually save your ankle from shattering.

What the Tests Don't Measure

Advanced boots prioritize protection against the catastrophic injuries common in high-speed crashes. These protective systems are complex and not easily captured by simple material tests.

Torsional and Hyperextension Control

The most critical function of a top-tier track boot is to prevent the ankle from twisting, breaking, or bending in unnatural directions.

This is achieved with rigid external bracing systems, often made of TPU and carbon fiber. These structures are the boot's most important safety feature, yet they have no bearing on the abrasion score of the underlying material.

System-Level Impact Management

A rigid external shell does more than just block impacts. It distributes the force of an impact over a much wider area, reducing the focal pressure on your foot and ankle.

A boot that relies solely on a thick, abrasion-resistant material cannot offer this same level of impact force distribution.

Understanding the Trade-offs

Choosing the right gear is about understanding the design philosophy and its associated compromises. No single product can be perfect in every isolated metric.

Test Optimization vs. Real-World Safety

A manufacturer could easily design a boot that achieves the highest possible score (Level 2) in the abrasion test by using a single, thick, and stiff material throughout its construction.

However, this boot would likely be extremely uncomfortable, offer poor control feedback, and lack the advanced anti-twist systems needed for track riding. The truly advanced boot prioritizes the complete safety system over excelling in a single material test.

The Role of Comfort and Control

Advanced boots use a strategy of zonal protection. They place the most robust materials and rigid structures in high-risk areas while using more flexible materials elsewhere to allow for the fine motor control needed to operate the motorcycle at its limit. This intelligent design is not always reflected in a simple certification score.

How to Evaluate a Boot Beyond the Label

Use the certification as a baseline, but apply your critical understanding to see the full picture. Your goal should guide your interpretation of the data.

- If your primary focus is maximum track safety: Prioritize boots with robust, external anti-torsion and hyperextension brace systems, even if their abrasion score is Level 1 instead of 2.

- If your primary focus is all-around road and touring use: A boot that achieves a consistent Level 2 rating across all categories may be a more balanced choice, as it indicates high material durability throughout.

- When reading any certification label: Look beyond the single number and investigate the features that the tests do not and cannot measure.

True expertise lies in understanding not just the test score, but the protective philosophy behind the boot's design.

Summary Table:

| Aspect | Standard Lab Test Focus | Advanced Boot Design Focus |

|---|---|---|

| Protection | Material abrasion & cut resistance on isolated samples | Rigid external armor, anti-twist bracing, hyperextension control |

| Test Method | Isolated flexible material samples | Complete boot system with carbon fiber/TPU braces |

| Real-World Safety | Limited to material durability | Full-force distribution, ankle protection in high-speed crashes |

| Certification Score | May show lower levels due to flexible chassis | Prioritizes holistic safety over isolated test metrics |

Need advanced protective footwear designed for real-world safety, not just lab scores?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities include track boots with advanced anti-torsion bracing, carbon fiber reinforcement, and zonal protection systems—engineered for maximum safety and control.

Contact us today to discuss custom solutions tailored to your safety requirements.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What is the core function of professional safety boots within a construction Health and Safety (H&S) management system? Beyond Protection: Boost Safety & Productivity

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites