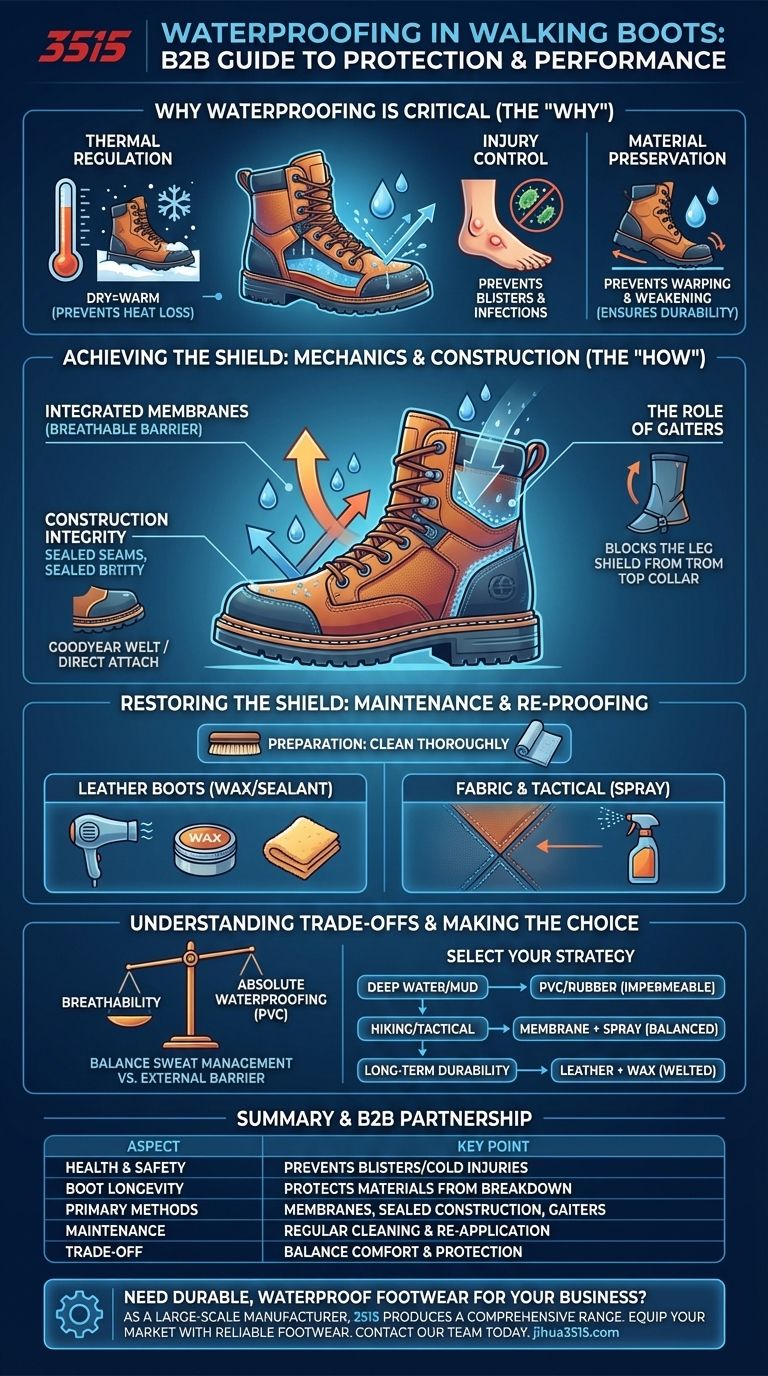

Waterproofing is the critical defense mechanism in footwear that preserves both the structural integrity of the boot and the physiological health of your foot. It is achieved through a multi-layered approach involving integrated membranes during manufacturing, precise construction techniques like sealed welts, and the regular application of hydrophobic treatments such as waxes or sprays.

True waterproofing is a system, not just a coating. It requires a balance of preventing external liquid intrusion while managing internal condensation to keep the foot dry, warm, and free from injury.

Why Dryness Equals Performance

To understand the importance of waterproofing, you must look beyond simply "getting wet." The implications of moisture penetration affect health, safety, and equipment longevity.

Thermal Regulation and Insulation

Water transmits heat significantly faster than air. If water saturates your boot, your feet lose heat rapidly, making it nearly impossible to stay warm in harsh winter weather.

Waterproof boots maintain a dry internal environment. This allows the insulation layers to trap heat effectively, preventing numbness or cold-related injuries.

Injury and Infection Control

Damp skin is soft, fragile, and highly susceptible to friction. Walking in wet socks is a primary cause of blisters and skin abrasion.

Furthermore, a warm, damp boot interior creates the perfect breeding ground for biological threats. Waterproofing prevents the bacterial and fungal growth that leads to unpleasant odors and infections like athlete's foot.

Material Preservation

Waterlogging is destructive to the boot itself. When leather or fabric becomes saturated, it expands, warps, and weakens.

By preventing saturation, waterproofing protects the fibers of the boot. This ensures the footwear remains durable and maintains its shape over years of use.

The Mechanics of Protection

Achieving a waterproof seal involves both the initial manufacturing of the boot and ongoing user maintenance.

Integrated Membranes

Most modern hiking and work boots utilize a waterproof membrane sandwiched between the outer layer and the inner lining.

This technology stops water droplets from entering but allows smaller sweat vapor molecules to escape. This breathability is vital to avoid condensation buildup from the inside.

Construction Integrity

Water often finds the path of least resistance, usually through seams or where the sole meets the upper.

High-quality boots utilize specific attachment methods, such as Goodyear welt construction or direct attachment, combined with internal waterproof seals. PVC boots take this further by offering a continuous, completely waterproof barrier, ideal for submersion.

The Role of Gaiters

Even the best boots cannot prevent water from pouring in over the collar.

Gaiters act as an external shield for the top of the boot. They are essential for preventing water entry when walking through deep snow, heavy rain, or wet grass.

Restoring the Shield: Maintenance and Re-proofing

Factory waterproofing is not permanent. You must re-establish protection using specific techniques based on your boot's material.

Preparation

You cannot seal a dirty boot. Dirt particles attract water and degrade coatings.

Clean the boots thoroughly with a stiff brush and rag before applying any treatment.

Treating Leather Boots

Leather requires conditioning to remain water-resistant.

- Warm the leather slightly with a hairdryer to open the pores.

- Apply a specialized sealant or wax evenly with a rag.

- Buff off the excess and allow it to dry.

Treating Fabric and Tactical Boots

Waxes are often too heavy for fabric or synthetic tactical boots.

Instead, use a waterproofing spray. Ensure you cover all weak spots, specifically targeting the seams and stitching where leaks are most likely to occur.

Understanding the Trade-offs

While waterproofing is essential, it introduces specific variables you must manage.

The Breathability Compromise

There is often a trade-off between absolute waterproofing and breathability. Materials like PVC provide a perfect barrier against external water but trap sweat completely.

If internal moisture (sweat) cannot escape, your feet will still end up wet. Membranes attempt to solve this, but high-exertion activities may still overwhelm the boot's ability to vent vapor.

Maintenance Dependency

"Waterproof" is a maintenance status, not a permanent feature.

Without regular cleaning and re-application of waxes or sprays, even expensive boots will eventually wet out. Neglecting this maintenance leads to material breakdown and waterlogging.

Making the Right Choice for Your Goal

Select your waterproofing strategy based on your specific environment.

- If your primary focus is deep water or mud: Prioritize PVC or rubber boots for a complete, impermeable barrier, accepting that sweat management will be lower.

- If your primary focus is hiking or tactical operations: Choose boots with breathable membranes and maintain them with sprays to balance weather protection with sweat release.

- If your primary focus is long-term durability: Opt for leather boots with welted construction and commit to a regular regimen of warming and waxing to seal the pores.

A proactive approach to waterproofing ensures that your footwear remains a tool for mobility rather than a source of discomfort.

Summary Table:

| Aspect | Key Point |

|---|---|

| Health & Safety | Prevents blisters, infections, and cold-related injuries by keeping feet dry and warm. |

| Boot Longevity | Protects materials from waterlogging, warping, and breakdown. |

| Primary Methods | Integrated membranes, sealed construction (e.g., Goodyear welt), and gaiters. |

| Maintenance | Regular cleaning and re-application of waxes (leather) or sprays (fabric/synthetics). |

| Trade-off | Balance between waterproofing and breathability is key for comfort. |

Need Durable, Waterproof Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof shoes and boots, from breathable membrane hiking boots to fully impermeable PVC work boots, ensuring your customers stay dry, safe, and comfortable.

Let us help you equip your market with reliable footwear.

Contact our team today to discuss your manufacturing needs and how we can add value to your product line.

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Who typically wears snake boots? Essential protection for hunters, hikers & field professionals

- Why is insulation important in snow boots? The Key to Warm, Dry Feet in Winter

- What are the main characteristics of traditional Western boots? Discover the Design Built for the Saddle

- What are the risks of inadequate snake protection? Avoid Six-Figure Medical Debt

- What materials are commonly used for the outsole of walking boots? Choose the Right Foundation for Your Journey

- What are the main types of tall riding boots? A Guide to Field, Dress, and Hunt Boots

- Why are walking boots important for walking or hiking? Essential Support for a Safe Adventure

- What are the main drawbacks mentioned about these boots? Avoid Costly Footwear Mistakes