At its core, a walking boot's outsole is most commonly made from rubber or specialized synthetic compounds like Polyurethane (PU) and Thermoplastic Polyurethane (TPU). These materials are selected for a precise balance of durability, traction, and stability, forming the critical connection between you and the ground.

The choice of an outsole material is not arbitrary; it's a deliberate engineering decision that balances the fundamental trade-offs between grip, long-term durability, and overall weight. Understanding these differences allows you to select a boot that is truly fit for your purpose.

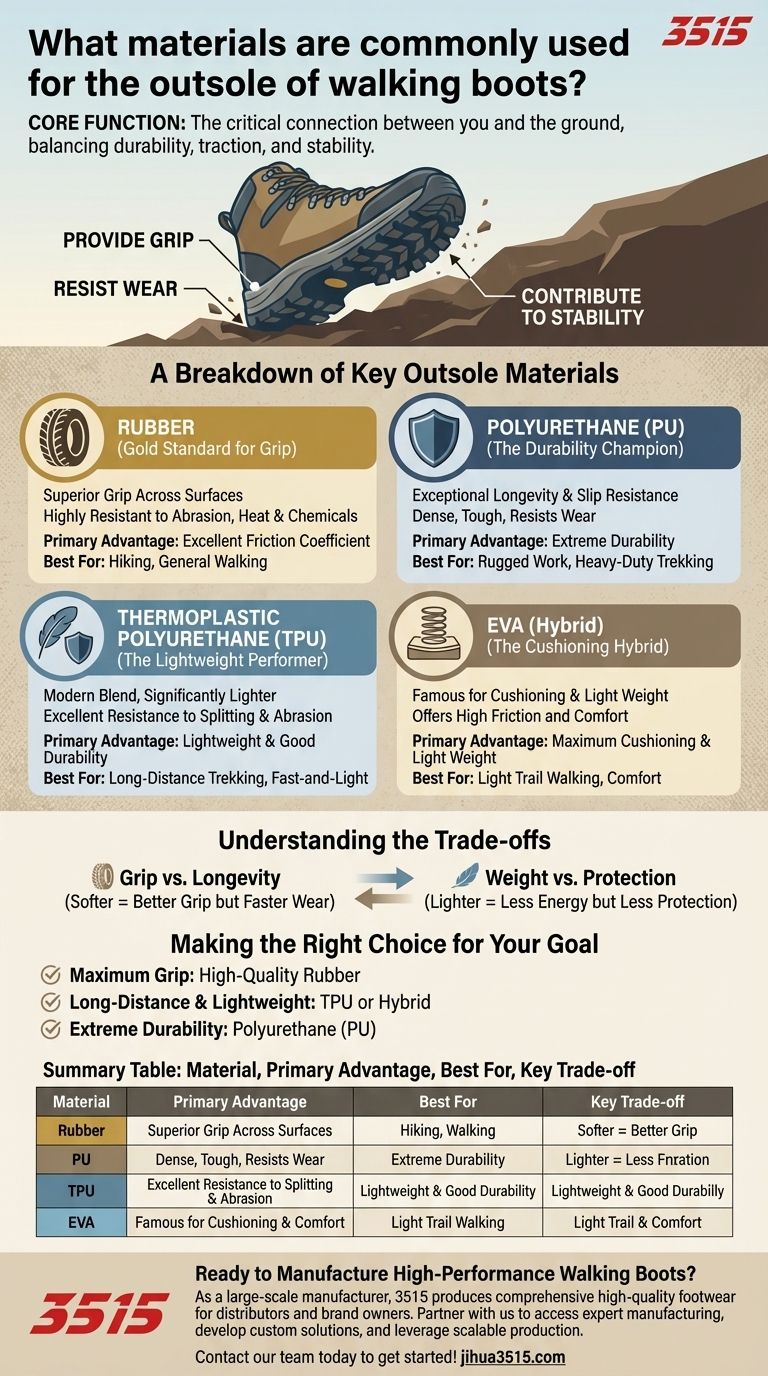

The Role of the Outsole: Your Foundation on the Trail

Before examining the materials, it's crucial to understand the outsole's function. It is the single point of contact with the terrain, responsible for three critical tasks: providing grip, resisting wear and tear, and contributing to the boot's overall stability.

The effectiveness of an outsole is determined by both its material composition and the design of its tread pattern, or lugs. The material dictates the inherent properties of grip and durability, while the lug pattern adapts that material to specific surfaces like mud, rock, or wet ground.

A Breakdown of Key Outsole Materials

Each material offers a distinct profile of strengths and weaknesses. The most advanced boots often use proprietary blends or dual-density constructions to optimize performance.

Rubber: The Gold Standard for Grip

Rubber is the most traditional and widely trusted outsole material. Its primary advantage is its excellent friction coefficient, which provides superior grip across a wide variety of surfaces.

It is highly resistant to abrasion, heat, and even chemicals like acids and alkalis, making it exceptionally durable for demanding use.

Polyurethane (PU): The Durability Champion

Polyurethane is a dense, strong polymer known for its exceptional longevity and slip resistance. Outsoles made from PU are incredibly tough and resist wear over long periods.

This durability often comes with slightly more weight, making PU a common choice for heavy-duty work boots or trekking boots designed for the most rugged environments.

Thermoplastic Polyurethane (TPU): The Lightweight Performer

TPU is a modern alternative that offers a compelling blend of properties. It is significantly lighter than traditional rubber or PU, which helps reduce fatigue on long hikes.

While providing good durability, its key advantage is its excellent resistance to splitting and abrasion in a lightweight package.

EVA: The Cushioning Hybrid

Ethylene Vinyl Acetate (EVA) is famous for its use in midsoles due to its fantastic cushioning and light weight. While less common as a primary outsole material, it is sometimes used in lighter walking shoes.

When used in outsoles, EVA provides high friction and comfort but typically offers less durability and protection than denser rubber or PU compounds.

Understanding the Trade-offs

There is no single "best" material; each one represents a compromise. Acknowledging these trade-offs is the key to making an informed choice.

Grip vs. Longevity

There is often an inverse relationship between grip and durability. Softer rubber compounds provide phenomenal traction because they conform to microscopic irregularities in the ground, but they also wear down faster.

Harder compounds, like those found in some PU outsoles, last longer but may offer less grip, especially on smooth, wet surfaces like rock or pavement.

Weight vs. Protection

Lighter materials like TPU and EVA are excellent for minimizing the energy you expend with each step. This makes them ideal for fast-and-light adventures or long-distance treks.

However, heavier and denser materials like rubber and PU provide more protection from sharp rocks and rough terrain, contributing to better foot stability and overall durability.

Making the Right Choice for Your Goal

Your intended use should be the ultimate guide in selecting an outsole material.

- If your primary focus is maximum grip and all-terrain reliability: Choose a boot with a high-quality rubber outsole, as its traction is the benchmark for performance.

- If your primary focus is long-distance trekking where weight is critical: Look for boots featuring lighter TPU or hybrid outsoles to reduce fatigue over many miles.

- If your primary focus is extreme durability for work or rugged off-trail use: A Polyurethane (PU) outsole will provide the best long-term resistance to wear and abrasion.

By understanding the properties of these core materials, you are empowered to choose a boot that performs as a reliable tool for your specific journey.

Summary Table:

| Material | Primary Advantage | Best For | Key Trade-off |

|---|---|---|---|

| Rubber | Superior Grip & All-Terrain Traction | Hiking, General Walking | Softer compounds wear faster |

| Polyurethane (PU) | Extreme Durability & Longevity | Rugged Work, Heavy-Duty Trekking | Heavier, can have less grip |

| Thermoplastic Polyurethane (TPU) | Lightweight & Good Durability | Long-Distance Trekking, Fast-and-Light | Less protection than denser materials |

| EVA (Hybrid) | Maximum Cushioning & Light Weight | Light Trail Walking, Comfort | Lower durability and protection |

Ready to Manufacture High-Performance Walking Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including specialized walking boots with outsoles engineered for specific performance needs—whether it's superior grip, extreme durability, or lightweight construction.

Partner with us to:

- Access expert manufacturing for rubber, PU, TPU, and hybrid outsoles.

- Develop custom solutions tailored to your target market's demands.

- Leverage scalable production to meet your volume requirements efficiently.

Let's discuss your next project. Contact our team today to get started!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the three main steps for proper cowboy boot care? Extend the Life of Your Boots

- What are the functional differences between winter boots and snow boots? Choose the Right Boot for Your Winter Needs

- What type of exercises are recommended during the non-weight bearing phase? Safely Maintain Strength While Healing

- Who are the Best Overall walking shoes recommended for? Ideal for Daily Comfort & Pain Relief

- What are the primary benefits of using horse boots? Enhance Performance & Prevent Injury

- What makes a winter boot suitable for extreme cold conditions? A Guide to Insulation, Waterproofing & Fit

- What is a CAM walker or walking boot? A Guide to Healing with Mobility

- What characteristics should walking shoes for bunions have? Find Relief with Spacious Toe Boxes & Flexible Uppers