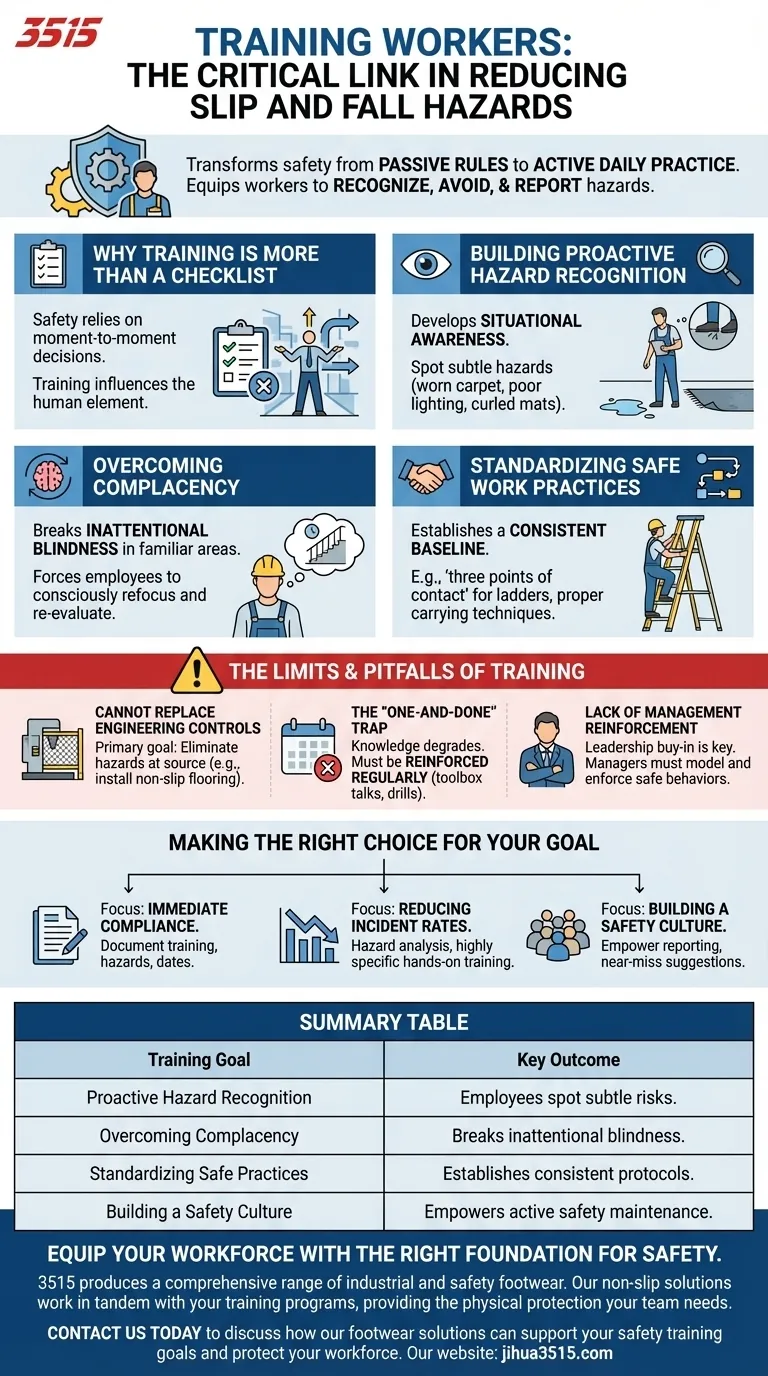

Training is a critical control measure because it transforms safety from a passive set of rules into an active, daily practice. It equips workers with the specific skills to recognize, avoid, and report slip, trip, and fall hazards before they can cause an injury, making each employee a vital part of the safety system.

The fundamental goal of training is not just to inform employees about dangers, but to change their behavior. It shifts their mindset from simply navigating their environment to constantly assessing it for potential risks.

Why Training is More Than a Checklist

Many workplaces have physical controls in place, yet incidents still occur. This is because a safe environment relies on the moment-to-moment decisions of the people within it. Effective training directly influences this human element.

Building Proactive Hazard Recognition

Training sharpens an employee's ability to see danger in everyday situations that might otherwise be ignored. This is often referred to as developing "situational awareness."

It moves employees beyond reacting to obvious problems, like a large spill, and trains them to spot subtle or developing hazards such as worn carpeting, a curled mat edge, or poor lighting in a stairwell.

Overcoming Complacency

In familiar environments, it is human nature to become complacent and stop actively scanning for risks. This is a cognitive bias known as "inattentional blindness."

Regular training sessions break this cycle. They force employees to consciously refocus their attention on their surroundings and re-evaluate areas they might otherwise take for granted.

Standardizing Safe Work Practices

Training establishes a clear, consistent baseline for safe behavior across the entire organization.

This includes specific protocols like the "three points of contact" rule for ladders, proper techniques for carrying objects to maintain a clear line of sight, and the immediate procedure for cleaning up a spill.

The Limits and Pitfalls of Training

While essential, training is not a cure-all. Viewing it as a standalone solution is a common and dangerous mistake. It is one part of a larger, comprehensive safety system.

Training Cannot Replace Engineering Controls

Training a worker to be careful around a machine with an unguarded moving part is far less effective than installing a proper guard on the machine itself. The safest systems are designed to be inherently safe, reducing reliance on human behavior.

Training is a secondary control. The primary goal should always be to eliminate or engineer out the hazard at its source, for instance, by installing non-slip flooring instead of just putting up "wet floor" signs.

The "One-and-Done" Trap

Safety knowledge degrades over time. A single orientation session or an annual video is insufficient to build a lasting safety culture.

Effective training must be reinforced regularly. This can be achieved through short daily toolbox talks, safety reminders, and periodic hands-on drills.

Lack of Management Reinforcement

If supervisors and managers do not model, enforce, and reward the safe behaviors taught in training, the entire program will fail.

Employees quickly learn which rules are taken seriously and which can be ignored. Leadership buy-in is the single most important factor in training effectiveness.

Making the Right Choice for Your Goal

To be effective, training must be tailored to the specific risks of your workplace and the goals of your safety program.

- If your primary focus is immediate compliance: Ensure your program documents who was trained, on what specific hazards, and on what date to satisfy regulatory requirements.

- If your primary focus is reducing incident rates: Conduct a hazard analysis to identify your top 2-3 slip and fall risks, then build highly specific, hands-on training around mitigating those exact issues.

- If your primary focus is building a long-term safety culture: Combine hazard identification training with programs that empower employees to report near-misses and suggest safety improvements without fear of reprisal.

Ultimately, a well-trained workforce doesn't just follow safety rules; they actively create and maintain a safer environment for everyone.

Summary Table:

| Training Goal | Key Outcome |

|---|---|

| Proactive Hazard Recognition | Employees spot subtle risks like worn flooring or poor lighting. |

| Overcoming Complacency | Regular sessions break the cycle of inattentional blindness. |

| Standardizing Safe Practices | Establishes consistent protocols like the 'three points of contact' rule. |

| Building a Safety Culture | Empowers employees to actively maintain a safer environment. |

Equip your workforce with the right foundation for safety.

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots designed to work in tandem with your training programs, providing the physical protection your team needs.

Contact us today to discuss how our footwear solutions can support your safety training goals and protect your workforce.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health