Understanding the structural anatomy of oil and slip-resistant shoes is a critical safety imperative. Because footwear is the second leading cause of workplace slips and falls, each component—from the outsole's tread to the midsole's support—directly contributes to preventing injury. A failure to match the shoe's specific features to the work environment negates its protective purpose.

A shoe is not a single safety feature but a system of components. True slip resistance is achieved only when the outsole design, midsole support, and upper materials are correctly matched to the specific floor surfaces and contaminants in your workplace.

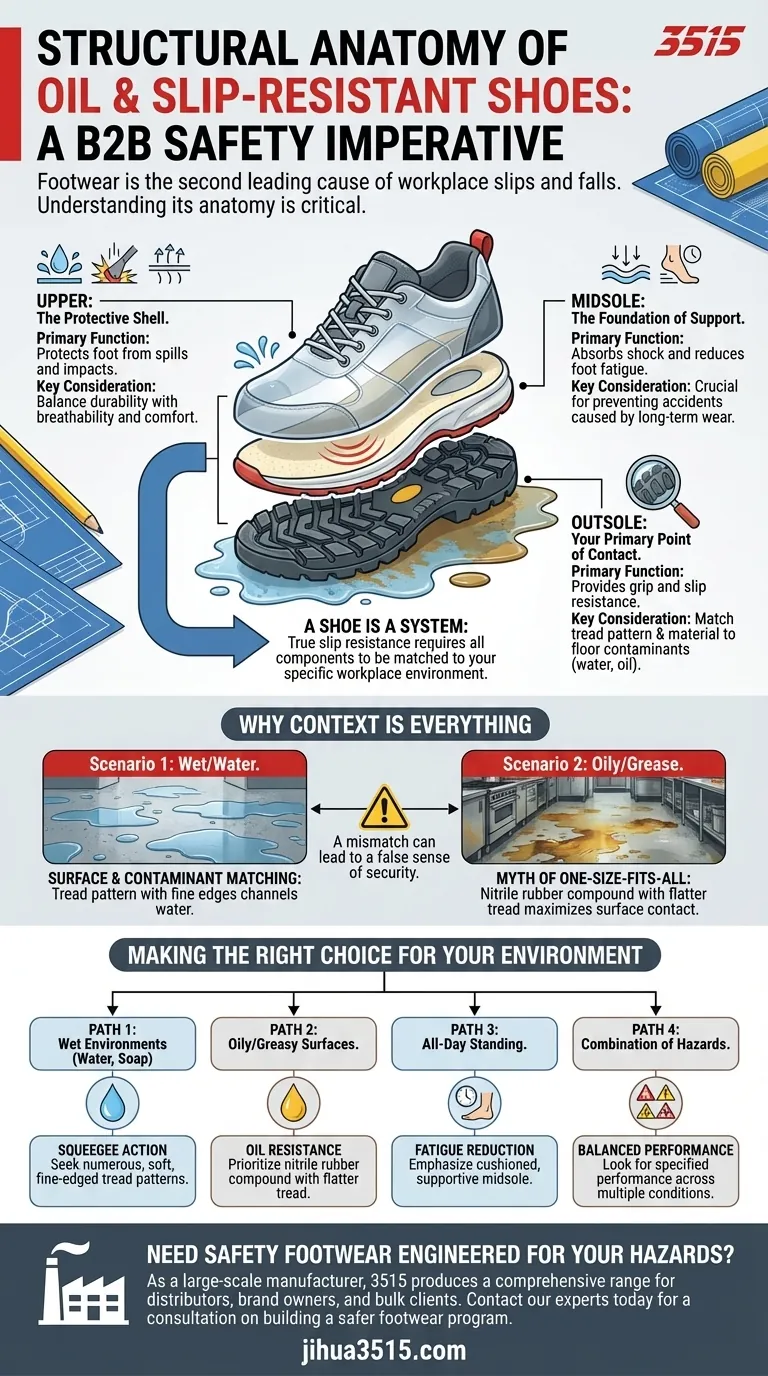

The Anatomy of a High-Performance Safety Shoe

To make an informed decision, you must evaluate a shoe as a complete system. Each part plays a distinct and vital role in ensuring both safety and performance.

The Outsole: Your Primary Point of Contact

The outsole is the layer that directly contacts the ground and is the most critical component for slip resistance. Its effectiveness is determined by its material composition and tread pattern. A rugged, well-designed outsole provides the necessary grip to maintain stability.

The Midsole: The Foundation of Support

Located between the insole and the outsole, the midsole provides cushioning and absorbs shock. A supportive midsole is crucial for reducing foot fatigue, which is a significant contributor to late-shift accidents and long-term musculoskeletal issues.

The Upper: The Protective Shell

The upper is the entire part of the shoe that covers the foot. In safety footwear, this component must be durable enough to protect against spills, splashes, and impacts while remaining breathable and comfortable enough for long-term wear.

Why Context is Everything

Simply choosing a shoe labeled "slip-resistant" is insufficient. The specific environment dictates which anatomical features are most important, and a mismatch can lead to a false sense of security.

Surface and Contaminant Matching

The most critical factor is the relationship between the shoe's outsole and the floor. A tread pattern with many fine edges designed to channel water may be ineffective on a floor with viscous oil.

Always check the shoe's specifications. Manufacturers often provide ratings for specific conditions, such as performance on water, oil, or a combination of contaminants.

The Myth of the "One-Size-Fits-All" Solution

There is no single shoe that provides maximum protection in every possible environment. A shoe that excels on a greasy kitchen floor may offer poor traction on a wet, uneven construction site.

This reality makes understanding your specific workplace hazards—the types of floors and the most common liquid contaminants—the first and most important step in developing a footwear safety program.

Making the Right Choice for Your Environment

To select the appropriate footwear, you must first define your primary operational hazard.

- If your primary focus is wet environments (water, soap): Seek outsoles with numerous, soft, and fine-edged tread patterns designed to squeegee liquid away from the sole.

- If your primary focus is oily or greasy surfaces: Prioritize shoes with a nitrile rubber compound outsole specifically rated for oil resistance and a flatter tread design that maximizes surface contact.

- If your primary focus is all-day standing on hard floors: Emphasize a cushioned, supportive midsole to combat fatigue, as this is a major indirect cause of accidents.

- If your primary focus is a combination of hazards: You must look for a shoe that specifies its performance across multiple conditions and accept the potential for compromised performance in any single area.

By treating shoe selection as a technical decision based on anatomy and environment, you can build a more effective and reliable safety program.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Outsole | Provides grip and slip resistance | Match tread pattern & material to floor contaminants (water, oil) |

| Midsole | Absorbs shock and reduces foot fatigue | Crucial for preventing accidents caused by long-term wear |

| Upper | Protects the foot from spills and impacts | Must balance durability with breathability and comfort |

Need safety footwear engineered for your specific hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of oil and slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed with the precise anatomical features to match your workplace environment—whether it's wet, oily, or requires all-day comfort.

Contact our experts today for a consultation on building a safer, more effective footwear program.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites