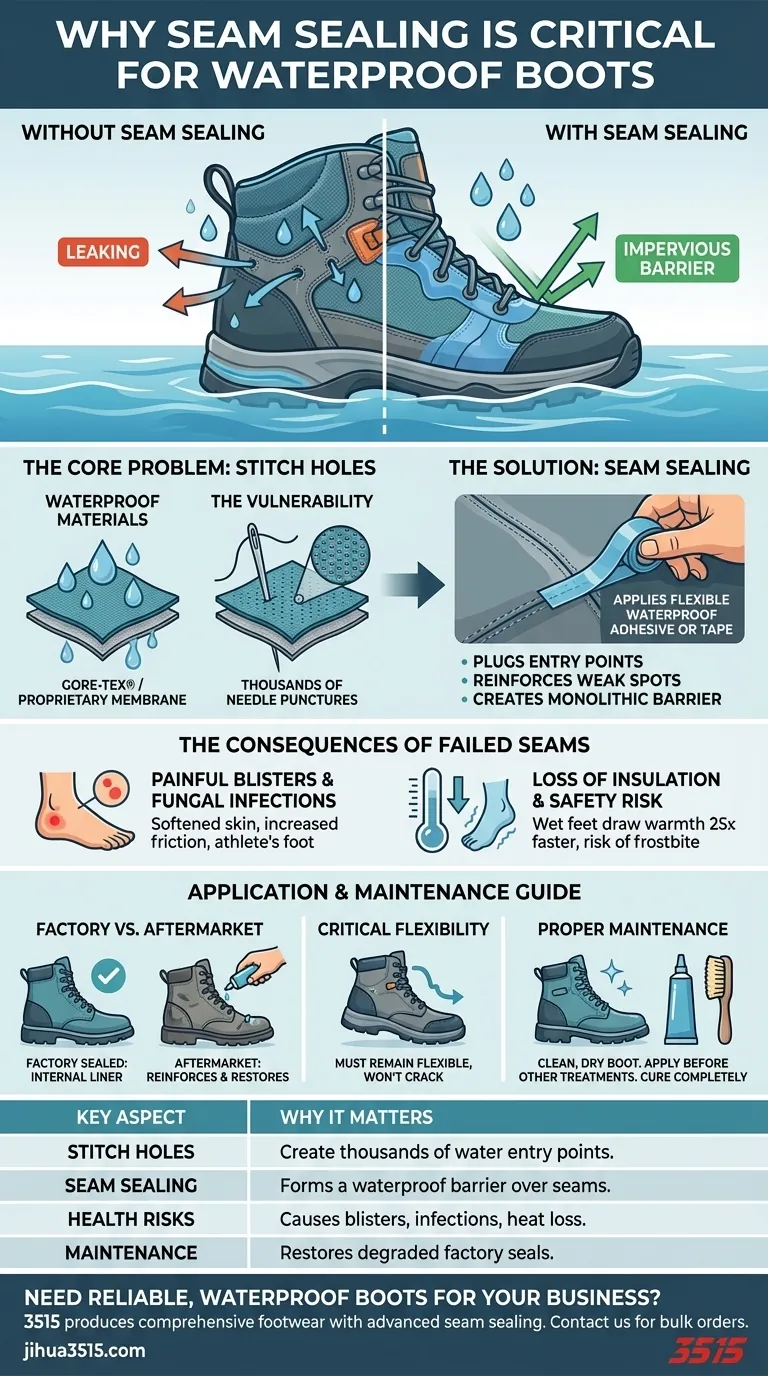

At its core, seam sealing is critical because it closes the biggest vulnerability in any waterproof boot: the stitch holes. While the materials used to construct a boot may be inherently waterproof, the process of stitching them together creates thousands of tiny punctures. Seam sealing applies a waterproof adhesive or tape over these seams, effectively plugging these entry points and preventing water from leaking through.

A waterproof boot is only as strong as its weakest point. Seam sealing addresses the thousands of needle holes created during manufacturing, transforming a collection of waterproof pieces into a single, truly impervious barrier against moisture.

The Anatomy of a "Waterproof" Boot

To understand the importance of seam sealing, you must first understand how a waterproof boot is constructed and where it can fail.

The Promise of Waterproof Materials

Most modern waterproof boots rely on advanced fabrics or liners, like Gore-Tex or other proprietary membranes. These materials are engineered to block liquid water from the outside while allowing water vapor (sweat) to escape from the inside.

The Inherent Problem with Stitching

The challenge arises when these waterproof materials are cut and stitched together to form the complex shape of a boot. Every single stitch from a sewing needle creates a small hole, compromising the integrity of the waterproof membrane.

Without treatment, these stitch holes act as direct channels for water to seep into the boot, bypassing the advanced waterproof material entirely.

How Seam Sealing Provides the Solution

Seam sealing is the essential process that neutralizes this vulnerability. A urethane-based adhesive or a special waterproof tape is applied over the seams, creating a durable and flexible barrier.

This seal covers the needle holes, reinforces what is often a weak spot in the boot's construction, and ensures the entire structure is monolithic against water intrusion.

The Consequences of Failed Seams

A boot with compromised seams isn't just slightly less effective; it fails its primary purpose and can introduce significant health and safety risks.

Beyond Simple Discomfort

Wet feet are far more than a minor inconvenience. They can lead to serious issues that can ruin a workday, a hike, or create long-term health problems.

The Health Risks of Wet Feet

Constant moisture inside a boot softens the skin, dramatically increasing friction and leading to painful blisters. Over time, this environment can cause swelling or foster fungal infections like athlete's foot.

Loss of Insulation and Safety

Water is a highly effective conductor of heat. Wet socks and feet will draw warmth away from your body 25 times faster than dry ones, severely compromising insulation. In cold weather, this can quickly lead to dangerously cold feet and increase the risk of frostbite.

Understanding Application and Maintenance

Seam sealing is not a one-time solution. It requires understanding how it's applied from the factory and how it should be maintained.

Factory vs. Aftermarket Sealing

High-quality waterproof boots come with factory-sealed or taped seams, typically on the interior waterproof liner. However, this sealant can degrade over time with wear and flexing.

Aftermarket seam sealers are liquid adhesives that you can apply externally to reinforce factory seals or restore waterproofing to older boots.

The Critical Role of Flexibility

A key property of any good seam sealer is its ability to remain flexible after it cures. Boots flex constantly with every step. A rigid sealant would quickly crack and fail, reopening the leaks it was meant to close.

Proper Maintenance is Key

When applying a seam sealer yourself, always start with a clean, dry boot. Apply the sealer directly to the seams before any other waterproofing sprays or conditioners. Allow it to cure completely according to the manufacturer's instructions for a strong, lasting bond.

How to Apply This to Your Boots

Your approach to seam sealing should match your intended use for the footwear.

- If your primary focus is casual wear in occasionally wet weather: Rely on the factory seam sealing of a reputable brand and visually inspect the seams for wear once or twice a year.

- If your primary focus is hiking or working in consistently wet environments: Choose boots with a high-quality, factory-taped internal liner and be prepared to apply an external seam sealer as a preventative maintenance step each season.

- If your primary focus is restoring an older pair of boots: Applying an aftermarket seam sealer to all stitched seams is the single most effective action you can take to bring back their waterproof performance.

Ultimately, paying attention to the seams is what transforms a water-resistant boot into a truly waterproof tool for keeping you dry, safe, and comfortable.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Stitch Holes | Thousands of tiny punctures created during manufacturing let water in. |

| Seam Sealing | Applies a waterproof barrier over seams to plug these entry points. |

| Health Risks | Wet feet lead to blisters, fungal infections, and loss of insulation. |

| Maintenance | Factory seals can degrade; aftermarket sealers restore protection. |

Need reliable, fully waterproof boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including models with advanced, factory-applied seam sealing for guaranteed waterproof performance. We ensure durability and comfort for your customers in any environment.

Contact us today to discuss your waterproof footwear needs and explore our extensive catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture