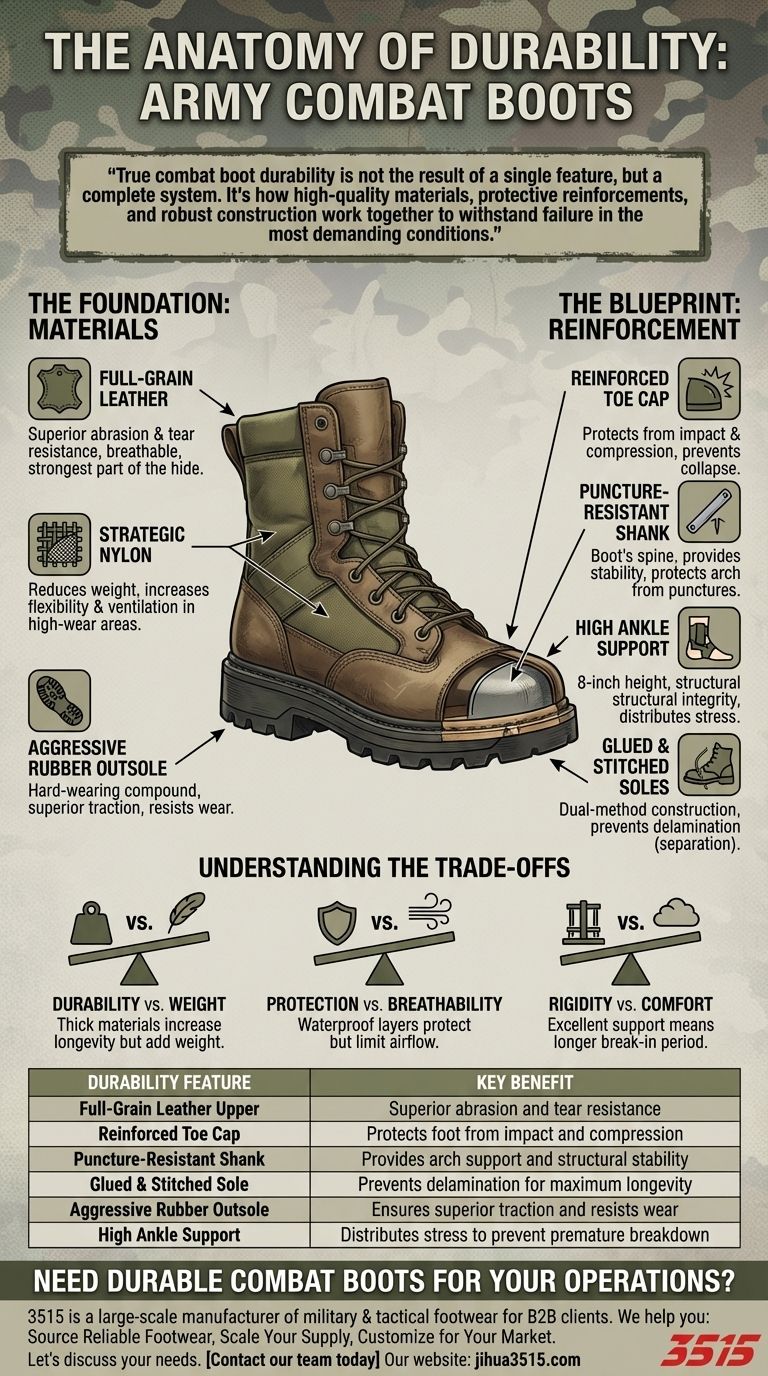

Beyond the tough exterior, the exceptional durability of army combat boots comes from a combination of specific materials, structural reinforcements, and proven construction methods. Key features include the use of full-grain cattlehide leather, reinforced toe caps and shanks, high ankle support, and rugged rubber outsoles that are both glued and stitched to the boot.

True combat boot durability is not the result of a single feature, but a complete system. It's how high-quality materials, protective reinforcements, and robust construction work together to withstand failure in the most demanding conditions.

The Foundation: Materials of Construction

The choice of material is the first and most critical step in building a durable boot. Each component is selected for its ability to resist wear, abrasion, and environmental stress.

Full-Grain Leather: The Gold Standard

Full-grain or flesh-out cattlehide leather is the primary material used for the boot's upper. Unlike corrected-grain leathers, it uses the strongest part of the hide, making it exceptionally resistant to tearing and abrasion while remaining breathable.

Strategic Use of Nylon

To reduce weight and increase flexibility without sacrificing strength, durable nylon panels are often integrated with the leather. This hybrid construction provides resilience in high-wear areas while allowing for better ventilation and a shorter break-in period.

The Aggressive Rubber Outsole

The outsole is made from a hard-wearing rubber compound designed for longevity and grip. The aggressive tread patterns, or lugs, provide superior traction on varied terrains like mud, rock, and sand, ensuring stable footing and resisting wear from constant friction.

The Blueprint: Structural Reinforcement

Beyond the base materials, a boot's longevity depends on its internal structure and how it is assembled. These reinforcements protect both the boot and the wearer from failure.

Reinforced Toe Caps

A reinforced toe cap, sometimes made of steel or a composite material, is built into the front of the boot. Its primary function is to protect the foot from impact and compression, but it also prevents the front of the boot from collapsing or splitting under stress.

Puncture-Resistant Shanks

A shank is a rigid piece of material, often steel, placed between the insole and outsole. It acts as the boot's spine, providing stability and protecting the arch of the foot from punctures from below. This structural element prevents the boot from flexing in the wrong places, which reduces long-term material fatigue.

High Ankle Support

The standard 8-inch height is not just for preventing ankle sprains. The tall, semi-rigid cuff provides structural integrity to the entire boot, distributing stress across a larger area and preventing the material around the ankle from breaking down prematurely.

Glued and Stitched Soles

One of the most critical durability features is how the outsole is attached to the upper. In high-quality combat boots, the sole is not only glued but also stitched on. This dual-method construction creates a powerful bond that is highly resistant to delamination (separation), a common point of failure in lesser boots.

Understanding the Trade-offs

No design is without its compromises. Acknowledging these trade-offs is key to understanding why certain features are chosen and what to expect from a genuine combat boot.

Durability vs. Weight

The features that make a boot durable—thick leather, steel shanks, and dense rubber soles—also make it heavy. While modern designs incorporate lighter materials like nylon, there is a direct correlation between maximum durability and increased weight.

Protection vs. Breathability

Waterproof membranes and thick, treated leather are excellent for keeping water out and protecting from hazards. However, they inherently limit airflow. This can lead to heat and moisture buildup inside the boot during strenuous activity in hot climates.

Rigidity vs. Comfort

The same features that provide excellent support and protection, like high ankle cuffs and rigid shanks, can feel restrictive. These boots often require a significant break-in period to conform to your foot and can lack the "out-of-the-box" comfort of lighter footwear.

Making the Right Choice for Your Goal

To select the right boot, you must align its features with your primary objective.

- If your primary focus is maximum protection and longevity: Prioritize boots with full-grain leather construction, a reinforced or steel toe, and dual-stitched soles.

- If your primary focus is mobility over long distances: Look for a hybrid leather-and-nylon design to save weight and improve breathability, while ensuring it still has a quality shank for support.

- If your primary focus is all-weather performance: Confirm the boot has a waterproof liner and an aggressively lugged outsole to handle wet and unpredictable terrain.

Understanding these core features allows you to look beyond marketing and select a boot built for genuine, long-lasting performance.

Summary Table:

| Durability Feature | Key Benefit |

|---|---|

| Full-Grain Leather Upper | Superior abrasion and tear resistance |

| Reinforced Toe Cap | Protects foot from impact and compression |

| Puncture-Resistant Shank | Provides arch support and structural stability |

| Glued & Stitched Sole | Prevents delamination for maximum longevity |

| Aggressive Rubber Outsole | Ensures superior traction and resists wear |

| High Ankle Support | Distributes stress to prevent premature breakdown |

Need Durable Combat Boots for Your Operations?

As a large-scale manufacturer, 3515 produces a comprehensive range of military and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable boots, built with the exact features detailed above to ensure they withstand the most demanding conditions.

We help you:

- Source Reliable Footwear: Get high-quality boots that meet your specific durability and performance requirements.

- Scale Your Supply: Benefit from our large-scale manufacturing capacity for consistent, bulk orders.

- Customize for Your Market: Work with us to develop or private-label boots tailored to your brand and customers.

Let's discuss your needs and how we can be your trusted manufacturing partner.

Contact our team today for a consultation

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- Why are army boots designed with high ankles? Essential Support & Protection for Demanding Environments

- How did punk culture in the 1980s reinterpret combat boots? From Military Gear to Symbol of Rebellion

- What are the key features of classic desert boots? A Guide to the Iconic Design

- What are the width measurements for men's boots in inches? Find Your Perfect Fit for All-Day Comfort

- What are the key features of army boots? Durability, Support & All-Terrain Traction Explained

- Why is polyurethane used in army combat boots? Superior Durability & Lightweight Support

- How will the jungle boots be distributed to soldiers? A Phased Rollout Plan Explained

- How did African-Americans in the 1960s use combat boots to symbolize their struggles? A Symbol of Black Power